What Is a Cushion Tank and How It Works in Industrial Water Systems

When you spend enough time around industrial water systems, you start to see the same issues repeat themselves. Unstable pressure, nuisance valve leaks, noisy pipes, or equipment that just does not last as long as it should. In many of those cases, the root cause is not the pump or the controls. It is how the system handles change. Water expands, temperatures shift, and pressure has to go somewhere.

This is where a cushion tank quietly does its job. It gives the system room to breathe as conditions fluctuate, helping absorb pressure swings before they stress piping, valves, or connected equipment. When sized and applied correctly, it protects the entire system without calling attention to itself. When it is missing or overlooked, operators usually find out the hard way.What a Cushion Tank Is and What It Actually Does

At its core, a cushion tank is a pressure-management device. It is installed in a water system to absorb expansion and stabilize conditions as operating demands change. As system water heats up or experiences load shifts, its volume increases. Without somewhere to go, that expansion pushes directly against pipes, valves, and equipment, raising water pressure and stressing the system. This is why cushion tanks are often grouped with expansion tanks. They serve the same essential purpose, which is to create a controlled space for expansion instead of forcing it into the rest of the system. Inside the tank, an air cushion compresses as water volume increases, allowing the system to adjust smoothly rather than react violently. When a cushion tank is missing or undersized, operators tend to notice the symptoms quickly. Pressure relief valves weep, pumps cycle more often, and fixtures in potable systems can chatter or bang. These are not random issues. They are clear signs that expansion is happening with nowhere to be safely absorbed.Thermal Expansion and Pressure Changes Inside Water Systems

Thermal expansion is one of those concepts that sounds simple until you see what it does in the field. As water heats up, its volume increases. In a closed system, that expanded water has no natural place to go. The result is rising pressure that pushes outward on every connected component. Pipes, heat exchangers, pumps, and valves all feel those expansion forces whether they are designed for it or not. Teams often see the effects first during changes in operating temperature. A system that runs quietly at startup may begin to show pressure changes as it reaches normal load. Gauges creep higher, relief devices activate, or fittings start to seep. Over time, repeated stress like this shortens equipment life and increases the risk of unplanned outages. Operators usually notice the damage after it has already started. Seals harden, joints loosen, and control components lose reliability. Managing expansion early keeps pressure stable and protects the system from the slow, costly wear that thermal expansion can cause when it is left unchecked.Key Components Inside a Cushion Tank

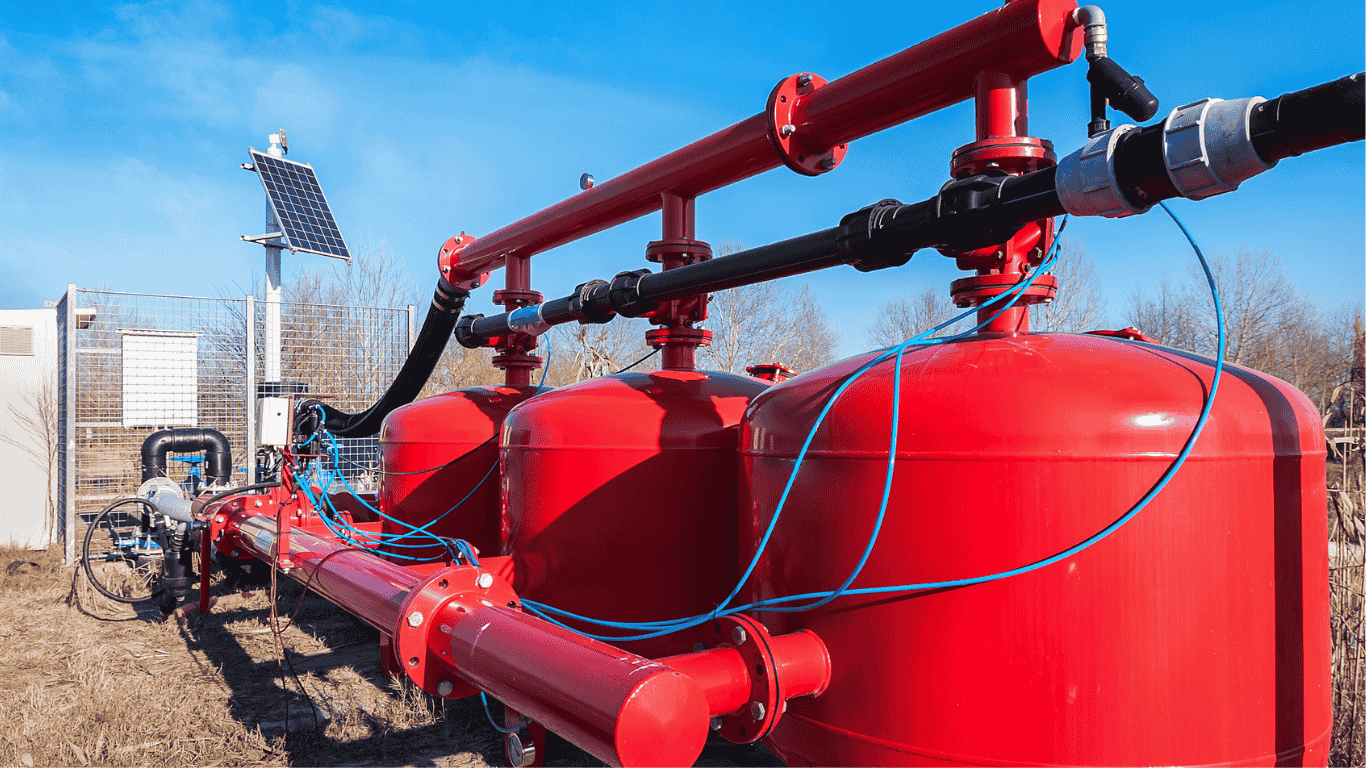

Inside a cushion tank, the real work happens where water and air are kept under control. Most tanks are designed with either a bladder or a diaphragm separating the system water from a sealed air or gas space. That separation matters. It allows the tank to manage changing volume without letting air dissolve into the water or migrate through the system. The air side of the tank is typically pre charged to a specific pressure before installation. That pre charged air compresses as water enters the tank, creating a flexible buffer that absorbs expansion. As system demand changes, the bladder or diaphragm moves back and forth, adjusting smoothly as gallons of water expand and contract. Failures usually show up when this balance breaks down. A damaged bladder can lose its ability to separate air from water, reducing effective volume and eliminating the cushion effect. Diaphragms can stiffen over time or rupture if operating conditions drift beyond what the tank was designed to handle. When that happens, the tank may still be installed and full of water, but it no longer protects the system the way it should.Where Cushion Tanks Are Used Across Heating, Cooling, and Potable Systems

Cushion tanks show up in more places than many teams realize. In heating applications, including hydronic heating loops, they manage expansion as water temperatures rise and fall throughout daily operation. Without that buffer, pressure swings can disrupt flow balance and strain components tied to the heating system. They also play a critical role in a cooling system, where temperature changes still occur even though the goal is heat removal. As loads shift and equipment cycles, expansion and contraction continue to happen. A properly applied cushion tank helps keep the system stable and prevents pressure-related issues that interfere with control and performance. In potable applications, cushion tanks are commonly installed near a water heater to protect pipes and fixtures from pressure spikes caused by heated water expanding. This is especially important in closed systems with backflow prevention, where pressure has nowhere else to relieve itself. When these tanks are integrated as part of a broader system design, such as those outlined in ProChem’s treatment system solutions, they support safer operation and help extend the life of connected equipment.Sizing, Installation, and Operating Conditions to Get Right

Sizing is where many cushion tank problems begin. Tanks range widely in capacity, and choosing the right size is not just about fitting what is available in the mechanical room. It depends on system volume, operating temperature, and how much expansion the system needs to absorb. When a tank is too small, it fills quickly and stops protecting the system, even though it may look fine from the outside. Installation details matter just as much. We often see tanks installed with the wrong diameter connection, isolated by closed valves, or tied into piping where they cannot respond effectively. In those cases, the tank exists, but it does not function as intended. Over time, that leads to unnecessary stress on pipes and control valves. Teams should also pay attention to working pressure limits and manufacturer instructions. Tanks should be tested periodically to confirm they are still operating within design conditions. A tank that is installed correctly but operated beyond its limits will fail just as surely as one that was undersized from the start.How Cushion Tanks Support Long-Term System Control and Reliability

A cushion tank is not a standalone fix. It works best when it is part of a broader approach to system control and reliability. By absorbing expansion and stabilizing pressure, the tank allows other components to operate the way they were designed to. Pumps cycle more predictably, valves seat properly, and controls respond consistently instead of chasing pressure swings. Over the long term, this stability reduces the risk of premature failure. Systems that manage expansion effectively tend to experience fewer leaks, fewer nuisance shutdowns, and better overall safety. Periodically tested tanks give operators confidence that expansion protection is still in place, even as system conditions evolve. Water quality plays an important role in maintaining that control. Corrosion, scale, and debris can interfere with valves and sensors, undermining otherwise sound control strategies. Pairing mechanical protection with well-designed chemical programs, such as those described in ProChem’s chemical program features, helps keep the entire system operating smoothly and reliably.Supporting System Performance with ProChem’s Services and Expertise

Over the years, we have seen that cushion tanks perform best when they are supported by consistent oversight and practical system knowledge. At ProChem, our services are built around helping customers understand how each component fits into the bigger picture, not just how a single product functions. That perspective allows teams to spot issues early and apply the right solution before small problems turn into larger ones. We work alongside operators to evaluate how tanks are sized, installed, and used within the system. This often includes reviewing operating conditions, water quality, and maintenance practices to make sure everything is aligned. When needed, we help facilities meet performance goals through ongoing support rather than one-time fixes. If you are looking for a more structured approach, our operations and maintenance services focus on protecting equipment, improving reliability, and supporting long-term system performance without unnecessary complexity.Practical Steps Operators Can Take to Avoid Cushion Tank Issues

Operators can prevent most cushion tank problems by staying observant and proactive. Regularly inspect the tank and surrounding piping for leaks, corrosion, or isolation valves that may have been left closed. Pay attention to system pressure trends during startup and normal operation. Sudden spikes or frequent fluctuations often signal that expansion is no longer under control. Do not ignore noise. Banging, hissing, or vibration near the tank or valves is usually an early warning that water expansion is stressing the system. When cushion tanks are undersized or overlooked, the entire system feels it. If you want to confirm that your expansion protection is aligned with current operating demands, connect with our experts for guidance grounded in real-world system performance.Frequently Asked Questions (FAQs)

How are expansion tanks designed to manage pressure in water systems?

Expansion tanks are designed to absorb the extra volume created when water heats up and expands. By providing a controlled space for that expanded water, they help cancel pressure spikes that would otherwise push into pipes, valves, and fixtures. This design keeps pressure within a manageable range and protects connected equipment from unnecessary stress.Are cushion tanks required in potable water systems?

In many potable water systems, cushion tanks are strongly recommended, especially when backflow prevention devices create a closed system. Without a tank, pressure can rise quickly when water is heated, leading to issues at the faucet, such as banging or intermittent flow. While requirements vary by location in the USA, most systems benefit from having expansion protection in place.How do I know how many gallons my system needs?

The gallons needed depend on total system volume, operating temperature range, and allowable pressure limits. Small tanks may seem adequate at first, but they often fill too quickly and stop providing effective expansion control. Reviewing system conditions before installation helps ensure expectations align with real operating demands.What should be checked before installing or replacing a cushion tank?

Before installation, teams should review prior system performance, pressure readings, and any history of relief valve discharge or leaks. Confirm that the tank size, working pressure rating, and connection points match the system. Tanks should also meet tested industry standards to ensure long-term reliability.Is it worth the money to upgrade or replace an older tank?

From a reliability standpoint, replacing a failing or undersized tank is often a smart investment. The cost to buy and install the right tank is usually far less than the expense of repairing pressure-related damage or dealing with unexpected downtime. Setting clear expectations around system performance helps guide better decisions and avoid recurring issues.How to Choose the Right Industrial Water Treatment Company

Choosing the right water treatment company is one of those decisions that tends to affect everything downstream. From system reliability to operating costs and long-term water quality, the partner you work with sets the tone for how your water is managed day to day.

In our experience, water treatment is rarely about a single product or quick fix. It is about understanding how water behaves in your facility and making informed choices that support performance, safety, and consistency over time.What a Water Treatment Company Really Does

A water treatment company should do much more than sell equipment and walk away. The real value comes from understanding how your water systems operate, where problems tend to show up, and which water treatment solutions actually make sense for your application. Over the years, we have seen facilities invest in systems that look good on paper but fail to solve the underlying water problems they were meant to address. Strong providers focus on listening first. They spend time learning how water moves through your operation, how it impacts equipment, and where risks or inefficiencies exist. From there, services are built around practical solutions, not just product catalogs. When systems are designed with real operating conditions in mind, customers see fewer surprises, more stable performance, and better long-term results.Understanding Your Water Before Choosing Solutions

Before selecting any equipment or treatment approach, teams need a clear picture of their water quality. Every source is different, and assumptions often lead to the wrong fix. Proper testing helps identify contaminants that cause scaling, corrosion, or performance loss. Hard water, elevated iron, sulfur compounds, or excess chlorine each create their own set of challenges, and they rarely show up the same way from site to site. Operators often notice early warning signs before data confirms them. A persistent water smell, staining, or unexplained water issues are usually symptoms of a deeper imbalance. Taking the time to analyze results and trace problems back to their source allows treatment strategies to be targeted and effective, rather than reactive or overbuilt.Treatment Systems Should Match Real-World Use

One of the most common mistakes we see is selecting water treatment systems based on trends instead of actual operating needs. What works well in one facility can create unnecessary complexity in another. The goal is to match treatment systems to how your water systems are used, how demand fluctuates, and what level of control operators realistically have day to day. Filtration and water filtration play a critical role here, but not every application needs the same water filter or level of equipment redundancy. Overengineering often leads to higher costs, maintenance headaches, and underutilized assets. A practical approach starts with performance requirements and builds outward. If you want a closer look at how different treatment systems are designed and applied, you can read more on our overview of industrial water treatment systems.Softening, Filtration, and Point-of-Use Decisions

Water softening is often misunderstood, especially when it is confused with general filtration. A water softener is designed to address calcium and other minerals that cause scale buildup. Softening protects pipes, plumbing fixtures, and appliances by reducing deposits that restrict flow and shorten equipment life. In many industrial facilities and operations, this alone can resolve recurring maintenance issues. Filtration serves a different role. It targets suspended particles and specific impurities, while softening focuses on mineral balance. Knowing where each approach fits helps avoid overlap or gaps in protection. When softening and filtration are applied intentionally, systems stay cleaner, maintenance becomes more predictable, and long-term operating costs stay under control. For a closer look at how these technologies work, explore our ion exchange and water softening systems.Drinking Water, Taste, and Daily Use Considerations

Water quality directly affects the people and processes within a facility. From employee drinking water stations to process and utility use, clarity and consistency matter. Hard water or lingering contaminants can impact taste, contribute to buildup, and create avoidable strain on equipment and downstream operations. A well-designed water treatment solution helps ensure drinking water within a facility is safe, reliable, and consistent. Teams often notice subtle improvements, such as better taste or fewer complaints, as early indicators that systems are operating as intended. Maintaining balanced facility water supports day-to-day operations and reinforces a safer, healthier work environment.Long-Term Support, Training, and Accountability

Installation is only the first step in a successful water treatment program. The systems themselves are important, but ongoing support and training are what keep them performing consistently. A knowledgeable team ensures operators understand how equipment works, when maintenance is needed, and how to respond to early warning signs before they become bigger problems. Access to services, whether routine check-ins or emergency support, helps customers protect their investment and avoid costly downtime. Facilities that prioritize long-term guidance often see smoother operations, fewer surprises, and better overall water quality. To explore how ongoing operations and maintenance services can support your systems, visit our O&M services overview.Building a Smarter Water Management Strategy

A strong water management strategy starts with a clear understanding of your facility’s unique needs. A trusted water treatment company will evaluate your systems, recommend water treatment solutions that address real challenges, and offer a complete line of options tailored to your operations. Partnering with experts ensures that your equipment is protected, maintenance is predictable, and resources are used efficiently, ultimately saving time and money. Teams often find that small adjustments, like aligning treatment schedules with usage patterns or updating filtration components, can have a big impact on system performance. Unsure about the right approach for your facility? Contact us today to discuss how our ProChem experts can help protect your systems, optimize performance, and improve long-term efficiency.Frequently Asked Questions (FAQs)

What should I look for in an industrial water system?

When evaluating an industrial water system, focus on water quality requirements, operational demands, and long-term maintainability. Systems should be designed to address hardness, filtration, or specific contaminants that impact equipment, processes, or compliance. Starting with a clear understanding of your water characteristics helps teams select effective filtration solutions without adding unnecessary complexity.Can water treatment improve the quality of drinking water in a facility?

Yes. Proper filtration and softening remove minerals, chlorine, and other contaminants that affect drinking water quality in commercial and industrial environments. Many facilities notice improvements at drinking stations or employee use points once treatment systems are operating correctly. These changes often indicate that the system is performing as intended.Is water treatment environmentally responsible for industrial operations?

Modern water treatment solutions are increasingly designed with environmental impact in mind. Systems that reduce waste, optimize chemical use, and improve water efficiency help facilities protect resources while meeting operational goals. Working with a recognized provider or global leader in innovation helps ensure sustainability is built into the treatment strategy.Can treatment systems support specialty or process-specific water needs?

Yes. Many water treatment companies offer a broad range of solutions tailored to specialty applications, including process water, cooling systems, or other industry-specific requirements. The right combination of equipment and filtration solutions helps maintain consistent water quality without creating additional operational risk.How do I know if I’m getting the right support from my water treatment provider?

Support should extend well beyond installation. A reliable provider offers training, routine service, and responsive assistance so teams can operate with confidence. Look for partners that deliver full-line solutions, proactive guidance, and consistent access to expertise when issues arise.Reverse Osmosis System Cost: What You Should Know

When evaluating a reverse osmosis system, it’s easy to focus on the sticker price of the equipment. We’ve seen many facility managers do this, only to be surprised later by hidden costs in installation, pre-treatment, and long-term operation. The true reverse osmosis system cost goes well beyond the RO unit itself, encompassing energy, maintenance, chemical use, and system monitoring.

Understanding these factors early helps operators and decision-makers plan budgets more accurately, avoid surprises, and select a system that meets both capacity and water quality requirements. Whether you’re considering a commercial RO system or exploring reverse osmosis water filters for industrial use, it’s essential to look at the complete picture.Industrial and Commercial RO System Costs

Understanding the industrial reverse osmosis system costs starts with recognizing how system type and capacity influence pricing. Industrial systems for manufacturing or large-scale water treatment typically range from $50,000 to $500,000, depending on production capacity and water quality requirements. Smaller commercial RO systems, used in hotels, restaurants, or office buildings, generally cost $10,000 to $150,000. A key factor in cost is gallons per day (GPD) capacity. Larger systems benefit from economies of scale, reducing cost per GPD. For example, a 1,000 GPD commercial RO system may cost $15–25 per gallon, while a 50,000 GPD industrial system drops to $5–10 per gallon. Water quality also plays a role. Systems treating variable feed water with high hardness or contaminants require more extensive pre-treatment, driving up costs. Selecting the right system type for your application ensures both efficiency and longevity. For a closer look at system options and features, check out our ProChem Systems Overview.Capital Expenses (CAPEX) Overview

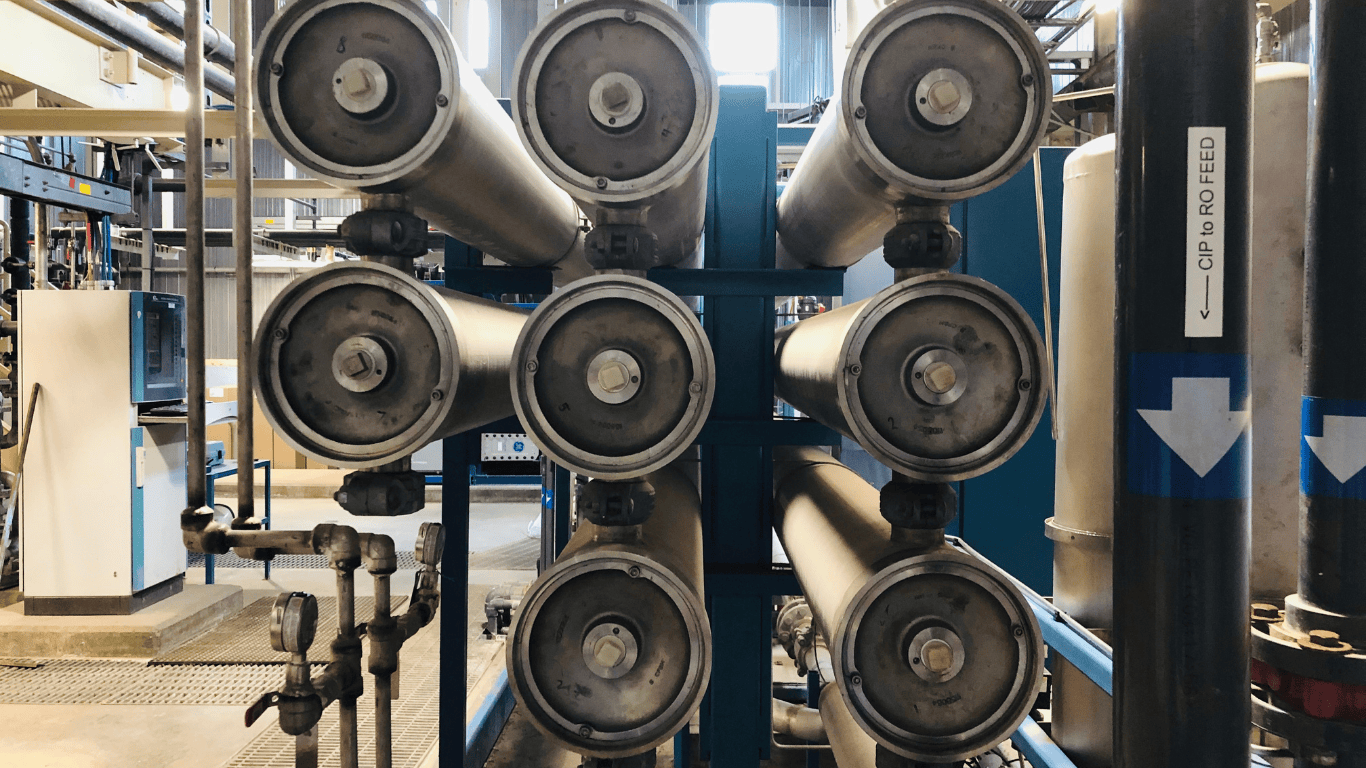

When planning a reverse osmosis system, understanding capital expenses (CAPEX) is crucial. The main components include core equipment like high-pressure pumps and RO membranes, pre-treatment systems, control instrumentation, and storage tanks. Installation costs can vary significantly based on system capacity, site conditions, and whether the project is a new installation or a retrofit. Smaller systems have lower absolute costs, but larger systems often offer better value per gallon treated due to economies of scale. Pre-treatment systems like multimedia filters and softeners, along with automation and controls, add upfront investment but protect membranes and extend system life. For a deeper look at membrane filtration systems and features, see our Membrane Filtration Systems page.Pre-Treatment and Post-Treatment Costs

Effective pre-treatment is essential to protect RO membranes and maintain long-term system performance. Multimedia filters, carbon filters, and water softeners remove suspended solids, chlorine, and hardness minerals that can foul membranes or reduce efficiency. Chemical dosing systems for scale inhibition and pH adjustment further safeguard the system while optimizing water recovery. On the post-treatment side, investment in storage tanks, disinfection, and remineralization ensures consistent water quality for end use. Stainless steel tanks offer superior durability and sanitary characteristics, while UV or ozone systems provide microbiological safety. Remineralization restores essential minerals removed during the RO process, producing treated water suitable for drinking, industrial applications, or food and beverage use. Properly designed pre- and post-treatment systems reduce maintenance costs, extend membrane life, and support reliable operation over the system’s lifespan.Operational Expenses (OPEX)

Once a reverse osmosis system is up and running, operational expenses (OPEX) become a significant part of total cost. Energy costs typically account for 40–60% of OPEX, driven by high-pressure pumps and recovery rates. Membrane replacement and filter replacements add ongoing expenses, with RO membranes typically replaced every 2–5 years depending on water quality. Chemicals for cleaning, scale inhibition, and pH adjustment further contribute to operating costs. Routine annual maintenance and system monitoring are critical. Operators often catch early issues by monitoring pressure and water quality trends, preventing costly downtime and membrane damage. Regular water testing ensures consistent water produced meets quality standards while avoiding regulatory issues. Investing in proactive maintenance and monitoring can significantly reduce long-term costs and extend system life. For tailored operational support, including preventive maintenance and troubleshooting, check out our ProChem Services offerings.Energy Efficiency and Recovery Optimization

Optimizing energy use is a key factor in managing reverse osmosis system cost. Recovery rates, which indicate how much feed water is converted into treated water, directly impact both water efficiency and energy consumption. Higher recovery reduces waste but may increase membrane fouling, so careful recovery rate optimization is essential for balancing efficiency and system longevity. Energy recovery devices, such as pressure exchangers, capture hydraulic energy from concentrate streams, reducing electricity demand by 30–60% in large systems. Variable frequency drives (VFDs) further enhance efficiency by adjusting pump speed to match demand, cutting energy costs while reducing mechanical stress. Modern RO systems increasingly include smart features that monitor performance in real time, providing alerts on pressure, flow, and water quality variations. These capabilities enable operators to make proactive adjustments, improving water efficiency, protecting membranes, and lowering overall operating expenses.Industrial vs. Commercial Systems

When comparing industrial and commercial RO systems, differences in system type and operational requirements are significant. Industrial systems prioritize reliability and continuous operation, often featuring redundant pumps, automated controls, and robust construction to handle high-capacity demands. These systems may include dual-train configurations and backup components, reducing downtime but increasing initial cost. Commercial systems, such as point of use systems or whole house RO systems, focus on space efficiency and integration with building infrastructure. Compact designs minimize installation complexity and disruption while meeting daily water quality needs. Regulatory considerations also vary. Industrial applications may require extensive monitoring, permitting, and compliance with discharge standards, whereas commercial systems primarily ensure safe potable water. Understanding these distinctions helps operators select the right system for their facility, balancing performance, cost, and long-term maintenance requirements.Real-World Applications and Costs

Understanding how industrial reverse osmosis systems and commercial RO systems perform in real-world settings helps guide budgeting and system selection. In pharmaceutical manufacturing, USP-grade water production requires validated systems with sanitary construction, often costing $100,000 to $750,000. Food and beverage processing systems emphasize clean-in-place capability and stainless steel materials, adding 40–80% to baseline costs while ensuring consistent water quality. Power generation facilities invest $200,000 to $2 million in RO systems for boiler feedwater, including degasifiers and polishing stages. Semiconductor manufacturing demands ultra-pure water with multiple treatment stages, driving costs above $500,000. On the commercial side, restaurants and hotels use RO systems to protect equipment and provide safe drinking water, typically costing $15,000 to $100,000 depending on capacity. Healthcare and educational facilities require reliable, high-quality water for laboratories, cafeterias, and patient care, influencing system size and complexity. Evaluating these examples highlights how application-specific requirements affect both upfront costs and long-term operation.Cost Optimization Strategies

Making your RO system cost effective requires planning beyond the initial purchase. Modular or phased implementation allows facilities to expand capacity over time while learning how to operate smaller systems efficiently. Standardizing equipment and components across multiple units reduces spare parts inventory, training needs, and simplifies filter changes. A proactive preventive maintenance program extends system life and minimizes unexpected downtime. Regular water audits help identify opportunities for improved recovery, energy savings, and better overall water efficiency. Choosing professional installation ensures proper setup and integration, preventing costly mistakes that can arise from improper commissioning. Partnering with experienced water treatment companies also provides access to expertise and optimization strategies tailored to your system 12 or other RO configurations. For additional support with chemicals, dosing, and pre-treatment optimization, see our Chemical Programs.Lifecycle and Total Cost of Ownership

When evaluating a reverse osmosis system, the total cost extends far beyond initial capital expenses. Over a 15–20 year lifecycle, operational expenses such as energy, maintenance, and membrane replacement often exceed the upfront investment, making it a big investment that requires careful planning. Financial analysis tools like net present value (NPV), internal rate of return (IRR), and payback period calculations help operators compare system options, quantify long-term savings, and justify investments. Considering residual value at the end of a system’s life, such as recoverable stainless steel or other materials, further refines cost projections. Choosing high-quality equipment at premium prices may seem costly initially, but it often reduces maintenance, extends system life, and lowers total lifecycle costs. Approaching RO system planning with a long-term perspective ensures informed decisions, reliable performance, and optimal return on investment.Steps to Reduce Reverse Osmosis System Cost

Here’s how I guide teams to manage reverse osmosis system cost without compromising water quality. Start by selecting the right system type for your application, balancing capacity, recovery, and complexity. Conduct thorough water testing to identify necessary pre-treatment and optimize chemical use. Implement preventive maintenance schedules and monitor water treatment performance to catch early issues, reducing unexpected downtime and costly repairs. Consider modular or phased expansions to spread capital investment over time. Standardizing components and filters simplifies maintenance and reduces operational overhead. Taking these steps ensures efficiency, reliability, and long-term savings. For a detailed assessment tailored to your facility’s needs, contact ProChem today for expert guidance and system analysis.Frequently Asked Questions (FAQs)

What are the benefits of installing a whole house RO system?

A whole house system treats all water entering your home, protecting plumbing, appliances, and fixtures from scale, chlorine, and other contaminants. It improves tap water tastes, ensures consistent water quality, and reduces reliance on bottled water. Unlike point of use systems, a whole house approach addresses water quality for showers, laundry, and cooking, providing comprehensive protection.How often should reverse osmosis filters and replacement filters be changed?

Filter life depends on water quality and usage. Pre-filters typically require replacement every 6–12 months, while RO membranes last 2–5 years. Keeping up with reverse osmosis filter and replacement filter schedules prevents fouling, maintains water efficiency, and extends system life. Monitoring water quality trends helps anticipate filter changes before performance declines.Can a countertop system provide the same quality as a home system?

Countertop systems are compact and convenient but usually treat smaller volumes than full home systems. They are suitable for drinking and cooking water but may not address whole house needs or post-treatment requirements. Consider your water demand and quality goals when choosing between a countertop or home system.Does RO water replace bottled water effectively?

Yes, a well-maintained RO system can produce purified water comparable to bottled water in taste and safety. Post-treatment, such as remineralization, can enhance flavor and ensure balanced mineral content, making it a sustainable and cost-effective alternative.What post-treatment options improve water quality?

Post treatment can include remineralization, UV disinfection, or activated carbon polishing. These steps enhance water taste, restore essential minerals, and provide microbiological safety. Proper post-treatment ensures that drinking water from your RO system is both safe and enjoyable.Reverse Osmosis Water Filtration System for Clean Water

After decades of working with facilities that depend on consistent water performance, one thing has stayed true. When teams need predictable results, flexibility, and confidence in what is coming out of the tap, reverse osmosis continues to stand apart. A reverse osmosis water filtration system is not a trend or a shortcut. It is a proven foundation that many industrial and commercial operations quietly rely on every day.

What makes reverse osmosis so valuable is its ability to adapt. It works across industries, across building sizes, and across very different water sources. Whether you are dealing with variable municipal supplies or trying to stabilize process water, it offers a level of control that other water filtration systems often struggle to match. Water quality affects more than compliance or taste. It influences equipment reliability, operating costs, and the consistency of finished products. For facilities responsible for delivering safe drinking water at scale, those details matter. Reverse osmosis gives teams a way to manage those variables instead of reacting to them. In the sections ahead, we will walk through how reverse osmosis fits into real-world operations and what teams should think about before putting it to work.What a Reverse Osmosis Water Filtration System Actually Does

At a practical level, a reverse osmosis water filtration system is designed to give operators control over what stays in the water and what gets removed. Instead of relying on chemical reactions or basic screens, it uses pressure and precision separation to consistently improve water quality. This approach is why reverse osmosis has become a cornerstone technology in facilities where variability in incoming water can create real operational headaches. The process itself is straightforward once you break it down.- Pressure drives separation. Incoming water is pressurized and directed toward a reverse osmosis membrane. This pressure is strong enough to overcome natural osmotic forces and push water molecules through the membrane surface.

- The membrane does the real work. The reverse osmosis membrane acts as a selective barrier. It allows water molecules to pass while rejecting most dissolved solids, including salts and other microscopic impurities that standard filters cannot reliably remove.

- Contaminants are concentrated and flushed away. Materials that cannot pass through the membrane are carried away in a separate stream, preventing buildup and helping maintain consistent system performance.

- Total dissolved solids are significantly reduced. Because separation happens at a molecular level, total dissolved solids drop dramatically, often by more than 95 percent when systems are properly designed and operated.

- Results stay stable even when conditions change. Reverse osmosis filtration delivers predictable output even if source water fluctuates. That consistency matters when downstream equipment or processes depend on tight water quality ranges.

Why Reverse Osmosis Delivers Consistent Water Quality

When operators talk about water problems, they are rarely talking about one bad day. The real challenge is inconsistency. Changes in source water show up as scaling, corrosion, taste complaints, or unexpected maintenance. Reverse osmosis addresses that issue by producing a stable output that facilities can rely on, shift after shift. By separating impurities instead of masking them, the system delivers purified water with predictable characteristics, even when incoming conditions fluctuate. The benefits show up in practical, measurable ways.- Water quality becomes repeatable. Reverse osmosis produces pure water by removing dissolved and suspended material at a molecular level. That consistency allows processes to be designed around the water, rather than constantly adjusting to it.

- Filtered water is safer to use across applications. Harmful contaminants such as heavy metals are rejected by the membrane, reducing the risk of long-term equipment damage and potential exposure concerns. The system also limits harmful microorganisms, which is especially important in applications tied to consumption or hygiene.

- Water tastes cleaner and more neutral. When excess dissolved material is removed, water tastes noticeably better. This matters in food service, beverage production, and anywhere users interact directly with the water.

- Downstream equipment stays protected. Stable, low-impurity water reduces scaling and fouling inside heat exchangers, boilers, and process equipment. Over time, this translates to fewer failures and more predictable maintenance schedules.

- Pure water supports operational confidence. Teams can trust that the water entering their systems meets the same standard every day, regardless of changes in the supply.

Industrial Applications Where RO Makes the Biggest Impact

In industrial settings, water is rarely just water. It is feedstock, a cleaning agent, a heat transfer medium, and sometimes a critical part of the final product. Over the years, we have seen that the facilities getting the most value from a reverse osmosis system are the ones using it to stabilize their operations, not just to meet a specification on paper. Different industries rely on RO for different reasons, but the underlying driver is always control.- Manufacturing and general process water. Many plants rely on municipal water or city water that fluctuates in quality. Changes in dissolved solids or chemistry can throw off production or damage equipment. RO systems create a predictable water supply, giving operators confidence that feed water conditions will not disrupt daily operations.

- Pharmaceutical and biotech facilities. These environments demand tight process control. Osmosis systems are often used as a core treatment step to produce consistent, high-purity water that supports formulation, cleaning, and validation requirements. Reliability matters here, because any deviation can shut down production.

- Food and beverage processing. Taste, safety, and equipment protection all intersect in this space. RO systems allow facilities to start with a neutral baseline, then adjust mineral content if needed. This approach protects boilers and heat exchangers while delivering consistent product quality batch after batch.

- Power generation and energy facilities. Boilers and turbines are unforgiving when it comes to water quality. A properly designed reverse osmosis system removes dissolved solids that lead to scaling and corrosion, helping extend asset life and reduce forced outages.

- Industrial reuse and recovery applications. Some facilities also use RO to treat waste water for reuse, reducing freshwater demand and easing discharge limits. When designed correctly, this can significantly lower operating costs tied to the overall water supply.

Commercial Uses That Depend on Clean, Predictable Water

In commercial facilities, water quality is something people notice right away. Guests taste it, staff use it constantly, and equipment depends on it to function properly. When water is inconsistent, complaints increase and operating costs rise. This is why many commercial teams rely on reverse osmosis to deliver dependable drinking water while reducing waste, simplifying operations, and supporting sustainability goals. The value of reverse osmosis shows up across a range of commercial environments.- Hotels and hospitality facilities. Guests expect clean, great-tasting drinking water throughout the property. Relying on bottled water often leads to storage challenges, recurring delivery costs, and excess plastic waste. By producing water on site, facilities reduce the need for purchasing bottled water and managing water bottles, while improving consistency and guest satisfaction.

- Healthcare environments. Hospitals and clinics require reliable water for patient care, food service, and sanitation. Reverse osmosis supports these needs by delivering consistent water quality and feeding systems that dispense hot water and instant hot water for beverages, cleaning, and clinical support, without consuming valuable counter space.

- Office buildings and corporate campuses. Providing high-quality drinking water encourages healthier habits and reduces reliance on bottled water programs. Centralized filtration gives employees easy access to clean water while lowering long-term operating costs tied to delivery and disposal.

- Food service and breakroom applications. Coffee machines, tea stations, and kitchen equipment perform more reliably when supplied with consistent hot water and filtered water. Stable water quality improves performance and extends equipment life.

- Sustainability and cost control. Producing water on site reduces plastic use, transportation emissions, and ongoing supply costs, while giving teams more control over water quality across the facility.

Pre-Treatment and Multi-Stage Filtration Matter More Than You Think

One thing we consistently see in facilities is that most reverse osmosis problems begin upstream. Even the most advanced membranes will struggle or fail prematurely if feed water isn’t properly prepared. That’s why effective pre filtration and multiple stages of protection are critical for keeping RO systems running smoothly. Proper upstream treatment ensures consistent water quality, extends membrane life, and reduces unexpected downtime. Here’s how pre-treatment and multi-stage filtration make a difference:- Sediment filters protect the membrane. A properly sized sediment filter removes dirt, silt, and other particles before they reach the reverse osmosis membrane. This prevents fouling, maintains efficiency, and reduces the frequency of membrane replacement.

- Carbon filters remove chemical threats. A carbon filter or carbon prefilter eliminates chlorine, chloramines, and other chemicals that can degrade membrane materials. Together with sediment filtration, these steps shield the system from the harmful effects of organic material and other contaminants.

- Multiple stages tackle diverse water challenges. Many facilities incorporate several pre filters in series to handle site-specific issues such as iron, manganese, hardness, or unusual organic material. Each stage contributes to cleaner feed water, ensuring the RO membrane operates under ideal conditions.

- Performance monitoring prevents surprises. Operators often track pressure drops and inspect upstream filtration components regularly. Doing so helps identify early issues before they impact water quality or membrane performance.

- Longevity and reliability pay off. Properly maintained multi-stage filtration keeps reverse osmosis systems producing consistent, high-quality water while minimizing operating costs and unplanned downtime.

System Design Factors Operators Should Pay Attention To

Even the most robust reverse osmosis water filtration system can underperform if key design factors aren’t carefully considered. While it’s easy to get lost in technical specifications, the elements that make the biggest difference are those that impact uptime, efficiency, and day-to-day operation. Here are the critical factors operators should watch:- Storage and water tanks. Proper sizing of the storage tank, water tank, or water reservoir ensures consistent availability of purified water during peak demand. Undersized tanks can cause frequent cycling, reduce system efficiency, and create pressure fluctuations.

- Feed pressure and flow. The RO membrane relies on adequate feed pressure to drive the filtration process effectively. Too low, and production slows; too high, and membranes experience unnecessary stress. Balancing pressure helps maintain steady output and extends membrane life.

- Waste ratio management. Modern RO systems can recover 75–85% of feed water, but the waste ratio is still an important factor. Efficient drain flow, often using a drain saddle, prevents backpressure and ensures consistent water quality while minimizing wasted water.

- Power consumption considerations. Energy use can vary with system design, feed water quality, and recovery targets. Understanding how design choices influence power consumption helps facilities manage operating costs and environmental impact.

- Operator interface and monitoring. Features like a digital display make it easier to track performance metrics, identify issues early, and schedule preventive maintenance. Clear, accessible controls reduce operator workload and improve response times when adjustments are needed.

- Accessibility for maintenance. Thoughtful placement of tanks, filters, and valves affects how quickly operators can perform routine cleaning, filter replacement, or membrane inspection. Easy access reduces downtime and keeps water quality consistent.

Maintenance Expectations and Long-Term Performance

Owning a reverse osmosis water filtration system is not just about installing the equipment and walking away. Long-term performance depends on routine care, preventive habits, and understanding how much maintenance the system truly requires. By setting realistic expectations, operators can protect both water quality and system longevity. Key maintenance considerations include:- Regular filter replacement. Replacement filters and timely filter replacement are critical for keeping the RO system functioning efficiently. Pre-filters remove sediment and chemical contaminants that would otherwise foul the RO membrane, so staying on schedule prevents performance drops and reduces the risk of premature membrane failure.

- RO membrane care. The ro membrane is the heart of the system. Depending on feed water quality and pre-treatment effectiveness, membranes generally last 2–5 years, but they require monitoring for signs of fouling, scaling, or chemical attack. Proper cleaning and periodic inspection help extend membrane life and maintain consistent RO water quality.

- Monitoring system performance. Tracking pressure differentials, flow rates, and water quality indicators allows operators to catch small issues before they escalate. Early detection of changes in performance minimizes downtime and keeps the system operating at peak efficiency.

- Preventive maintenance habits. Teams often overlook simple preventive steps, like flushing lines, inspecting seals, or checking storage tanks. These small habits can dramatically reduce emergency repairs and ensure steady output.

- Professional support when needed. Engaging expert services helps optimize schedules, troubleshoot complex issues, and ensure that the system continues delivering high-quality water. Facilities can learn more about these strategies in our Operations & Maintenance guide, which provides practical insights for keeping RO systems running reliably.

Reverse Osmosis in Broader Water and Wastewater Strategies

Reverse osmosis is often thought of as a standalone solution, but its real value shines when integrated into a larger water management strategy. By treating both incoming and outgoing streams, RO systems help facilities optimize fresh water use, reduce waste water, and protect against water contamination throughout the process. The RO process produces high-quality water, but it also generates leftover water that contains concentrated impurities. Rather than discarding this stream, many facilities find ways to treat or repurpose it, turning a potential waste product into a resource. For example, water that would normally go to drain can be used for non-product applications, cooling, or cleaning, depending on treatment levels and regulatory requirements. Incorporating reverse osmosis into a comprehensive strategy offers multiple benefits:- Conservation of fresh water. By recycling water through the RO process, facilities reduce reliance on municipal supply and protect valuable freshwater resources.

- Minimized wastewater impact. Proper management of leftover water helps facilities meet discharge regulations while supporting sustainability initiatives.

- Enhanced protection against contamination. RO serves as a critical barrier for both chemicals and microorganisms, reducing the risk of contamination downstream in processes, storage, or final product use.

- Process integration opportunities. RO can work in tandem with pre-treatment systems, chemical programs, and other filtration technologies to create a fully optimized water management system.

Building the Right Reverse Osmosis Strategy for Your Facility

Creating a reliable reverse osmosis water filtration system starts with understanding your facility’s unique water needs. Not all water is created equal, and neither are filtration systems. Evaluating the quality of your feed water, anticipated flow rates, and the types of contaminants present lays the groundwork for a system that delivers consistent results over time. Effective planning goes beyond the RO membrane itself. Water filters, pre filters, and other filters work together to protect the system, extend component life, and maintain stable water quality. In larger or multi-point applications, even whole house considerations come into play, ensuring that water reaches all points of use with the same consistency and reliability. Operators often find the biggest gains by pairing proper system design with proactive maintenance practices. Regular monitoring, scheduled filter replacement, and attention to upstream water quality are small steps that prevent large issues down the line. Unsure about how to balance design, pre-treatment, and maintenance for your facility’s RO system? ProChem provides guidance and expertise to help operators develop a strategy that fits their operational goals. Start by reviewing your water quality needs, mapping your system requirements, and identifying areas where pre-treatment or additional filtration will make a measurable difference. Taking these steps ensures your facility benefits from reliable, high-quality water while minimizing downtime and operational risk.Frequently Asked Questions (FAQs)

What are the benefits of using alkaline filters with reverse osmosis systems?

Alkaline filters can be added after the RO membrane to restore essential minerals and beneficial minerals that may be removed during filtration. This improves the taste of RO water and can contribute to healthier mineral content in drinking water, helping facilities provide a more balanced and enjoyable water experience.Can a reverse osmosis system remove harmful bacteria from drinking water?

Yes, the RO process is highly effective at reducing microorganisms. While membranes remove the vast majority of bacteria, pairing the system with proper pre-treatment and routine maintenance ensures consistent performance and minimizes risks, helping facilities kill bacteria before water reaches users.Are there point-of-use options like pitcher filters or glass pitchers?

For smaller or individual needs, pitcher filters and glass pitchers equipped with RO or carbon filtration provide convenient, high-quality drinking water. These options are ideal for breakrooms, offices, or situations where installing a full system isn’t practical, while still offering improvements in taste and purity.How can RO systems help facilities save money?

By reducing or eliminating the need for bottled water deliveries, facilities can significantly save money over time. Centralized RO systems, combined with well-maintained water filters, provide consistent, purified water on demand, lowering operational costs and reducing reliance on single-use plastics.Does RO water remove healthy minerals, and should that be a concern?

Reverse osmosis removes many dissolved solids, including healthy minerals naturally present in water. While this can slightly reduce certain nutrients, many systems include remineralization options to reintroduce beneficial minerals and improve taste. Facilities can balance purification with mineral content to meet both quality and health objectives.Efficient Solutions in the Wastewater Treatment Process

Every day, facilities generate wastewater that carries more than just used water. It contains solids, organic material, chemicals, and pollutants that can impact equipment, people, and the surrounding environment if left unmanaged. The wastewater treatment process exists to control those risks and to ensure water is handled responsibly before it is released, reused, or returned to the natural system.

At its core, wastewater treatment is about protecting water quality while keeping operations stable and compliant. When treatment steps work together as intended, they reduce environmental impact, support regulatory requirements, and help facilities operate more efficiently over the long term. In this guide, we'll walk through how wastewater moves through a treatment system, from the first point of entry to final discharge. Each stage plays a specific role, and understanding how they connect makes it easier to identify issues early, improve performance, and make informed decisions about system design and operation.What Is Industrial Wastewater and Why It Requires Treatment

Industrial wastewater is the by-product of everyday operations across manufacturing, food processing, power generation, and chemical production. Unlike domestic sewage, this wastewater can vary widely in temperature, flow, and composition depending on the process that created it. One shift change, a new raw material, or a cleaning cycle can quickly change what is entering the system. This water often carries a mix of suspended solids, oils, chemicals, and other pollutants that cannot be discharged safely without treatment. If left untreated, these materials can damage downstream equipment, disrupt biological activity, and degrade water quality in rivers, lakes, and other receiving bodies. Operators usually see the early warning signs first, unusual odors, excessive foaming, or solids settling where they should not. Proper wastewater treatment addresses these risks by removing contaminants in a controlled, predictable way. It protects infrastructure, helps facilities meet discharge limits, and reduces the environmental impact of industrial waste. More importantly, it gives operators consistency, which is critical when process conditions change and systems are pushed to perform every day.Preliminary Treatment – Protecting the Treatment Plant

Preliminary treatment is the first stage where incoming wastewater is physically controlled before it reaches the core of the treatment plant. The goal here is simple but critical, protect downstream equipment and create stable conditions for every step that follows. When this stage is overlooked or undersized, operators usually feel the impact quickly through clogged lines, damaged pumps, or inconsistent flow. At this point, wastewater passes through screening equipment designed to remove large solid materials such as rags, plastics, wood, and debris. These items do not break down and can cause serious mechanical issues if they move deeper into the system. Floating grease and oils are also separated early, reducing buildup in pipes and tanks and helping maintain consistent hydraulic performance. Well-designed preliminary treatment depends on selecting the right headworks layout and system capacity for real operating conditions. Facilities that invest in properly configured treatment systems are better equipped to handle flow variation and debris loading without disruption, ensuring this first stage consistently protects downstream processes and equipment.Screening and Grit Removal Equipment

The effectiveness of screening equipment goes beyond simply catching debris. The type, spacing, and maintenance of screens directly influence how smoothly the rest of the system operates. When screenings are inconsistent or overloaded, downstream tanks and pumps tend to absorb the stress, leading to uneven flow and higher wear on mechanical components. After larger debris is removed, grit removal focuses on dense materials such as sand and small inorganic particles that settle quickly. These materials may seem harmless, but over time they erode pumps, valves, and piping. Grit chambers are designed to slow the water just enough to separate these heavy particles without allowing organic material to settle with them. When grit removal is undersized or poorly tuned, operators often see buildup in tanks and reduced hydraulic capacity. Grease removal also plays a role at this stage, especially in industrial systems with variable loading. Oils and grease that are not separated early can coat surfaces and interfere with flow distribution. By selecting the right screening and grit removal equipment, facilities reduce mechanical strain, improve reliability, and keep wastewater moving predictably as it is pumped to the next treatment stages.Primary Treatment – Slowing the Water to Let Solids Settle

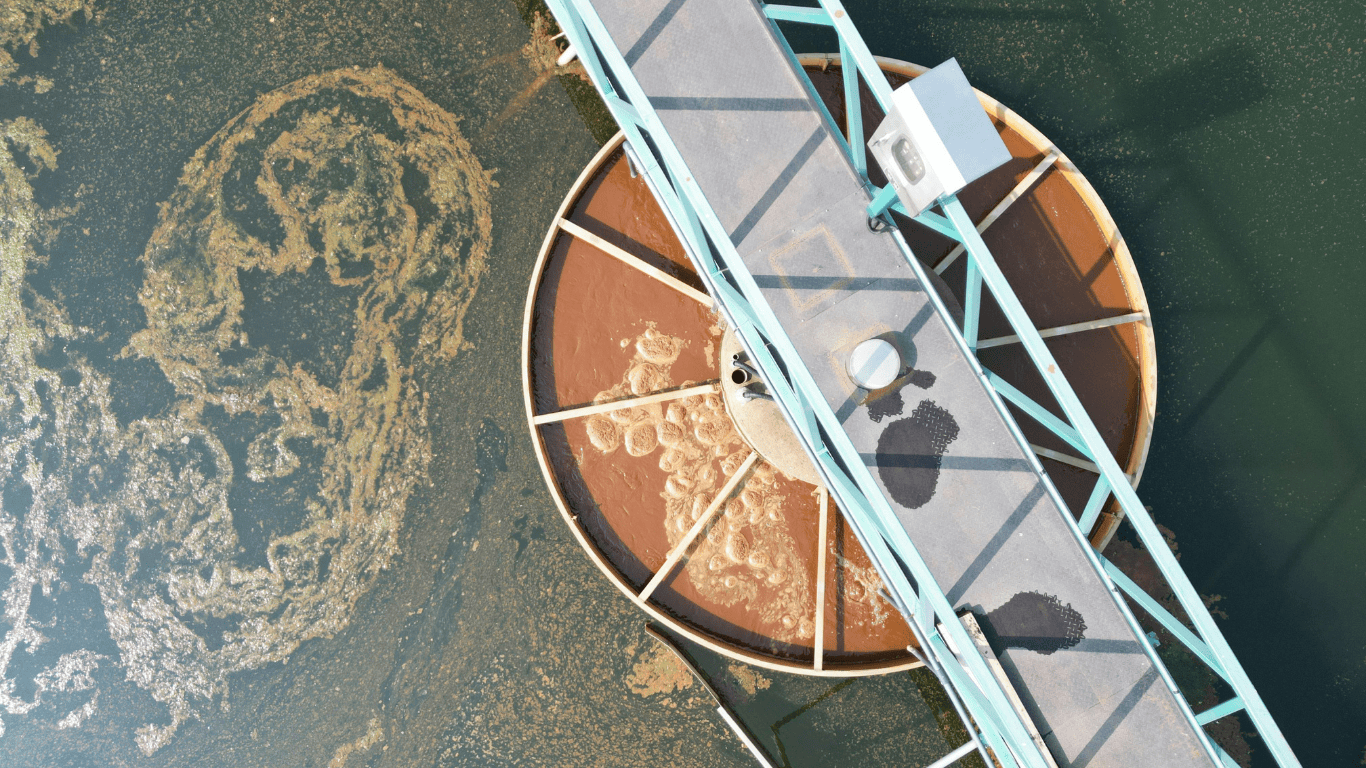

Primary treatment is where the wastewater treatment process begins to rely on time and gravity rather than mechanical separation alone. After preliminary steps, wastewater enters the primary treatment stage and is directed into a settling tank designed to slow the flow. As water slows, heavier solids naturally sink to the bottom while lighter materials move to the surface, creating clear separation zones within the tank. This stage is especially effective at removing suspended solids and a portion of the organic matter that would otherwise place unnecessary load on downstream biological systems. The goal is not to remove everything, but to take out what can be separated easily and efficiently. When primary settling is working properly, it creates more consistent conditions for secondary treatment and reduces energy demand later in the process. Operators often notice the impact of primary treatment in how stable the system feels day to day. Poor settling leads to solids carryover, while well-managed tanks deliver predictable performance. Maintaining proper detention time, sludge removal rates, and flow balance ensures that solids are captured where they belong, setting up the rest of the treatment process for success.Primary Settling Tanks and Sludge Collection

Once wastewater enters primary settling tanks, gravity takes over as the main driver of separation. These tanks are designed to create calm, controlled conditions where solids can settle without disruption. Operators rely on this stage to consistently remove material that would otherwise overload downstream processes, so attention to detail here makes a noticeable difference in overall plant stability.- In primary clarifiers, flow is distributed evenly to prevent short-circuiting, allowing heavier particles to sink and form primary sludge at the bottom of the tank. When distribution is uneven, solids tend to escape before they have time to settle.

- The sludge collected in these tanks must be removed at the right rate. If sludge sits too long, it can go septic and float, reducing separation efficiency and creating odors that operators recognize immediately.

- These tanks called settling basins also require routine inspection of scrapers, weirs, and hoppers. Small mechanical issues often show up first as rising sludge blankets or inconsistent effluent quality.

Secondary Treatment – Letting Biology Do the Heavy Lifting

Secondary treatment is where the wastewater treatment process shifts from physical separation to biological work. At this stage, the focus is on removing dissolved and finely suspended organic material that primary treatment cannot capture. Instead of relying on equipment alone, the system uses carefully managed biological processes to stabilize the wastewater before it moves forward. Bacteria and other microorganisms are introduced or encouraged to grow in controlled environments where they can consume organic material as a food source. As these microorganisms grow, they convert waste into new biomass and simpler compounds that are easier to separate from the water. Operators often think of this stage as keeping the biology healthy, because when conditions are right, the system largely takes care of itself. What matters most here is balance. Too little food, oxygen, or mixing slows biological activity, while too much loading can overwhelm the system. Temperature shifts, flow swings, and chemical upsets are usually felt first in secondary treatment. By understanding how these biological systems respond, operators can make small adjustments early and prevent larger disruptions that affect effluent quality and overall plant performance.Aeration Tanks and Activated Sludge Systems

Aeration tanks are the heart of secondary treatment, where wastewater and microorganisms meet under carefully controlled conditions. In these tanks, activated sludge systems use helpful microorganisms to break down organic material, transforming it into biomass that can later be separated from the treated water. Proper operation of these tanks is essential to maintaining a healthy biological population and ensuring the efficiency of the overall treatment process.- Wastewater is thoroughly mixed to keep microorganisms in contact with the organic material they consume. This ensures that the biological processes are consistent and complete, rather than leaving untreated pockets in the tank.

- Air is pumped into the tanks through diffusers or mechanical aerators, supplying oxygen that microorganisms need to thrive. Adequate aeration maintains microbial activity, supports the breakdown of organic matter, and prevents anaerobic conditions that can produce odors.

- Activated sludge, rich in bacteria and other helpful microorganisms, circulates within the tank. Operators monitor the sludge to ensure the right balance of organisms, solids, and oxygen is maintained, allowing the system to handle variable flows and loads without losing efficiency.

Secondary Clarifiers and Biomass Separation

After aeration tanks, treated wastewater flows into secondary clarifiers, where the focus shifts from biological activity to solid-liquid separation. These clarifiers allow biological sludge to settle, separating it from the clearer effluent above. Proper settling ensures that the treated wastewater leaving the system meets quality standards and is ready for further polishing or discharge. Secondary clarifiers are designed to provide enough detention time for solids to settle naturally. As the biological sludge sinks to the bottom, it can be collected and either returned to the aeration tanks to maintain microbial populations or sent to sludge treatment for further processing. Operators watch closely for signs of poor settling, such as floating solids or turbid effluent, which indicate imbalances in the system. By effectively separating biomass, secondary clarifiers protect downstream processes, maintain effluent quality, and support the continuous performance of the wastewater treatment plant. Settling in these tanks is a critical step, turning the biological work from the aeration tanks into a manageable, concentrated form.Tertiary Treatment – Polishing Treated Water

Tertiary treatment is the final stage of the wastewater treatment process, focusing on refining treated water to a level suitable for reuse or safe discharge. While secondary treatment removes most organic material, tertiary treatment targets residual contaminants and ensures the highest water quality. This stage is essential when water must meet stricter standards for industrial reuse, irrigation, or environmental release.- Filtration systems are commonly used to remove remaining suspended solids, fine particles, and microorganisms. Options include sand filters, activated carbon, and advanced membrane systems, each tailored to the specific needs of the facility. Proper filtration ensures that treated water reaches a purified state without leaving unwanted particles behind.

- Nutrient and contaminant removal is another key component, targeting substances like phosphorus and nitrogen that can cause ecological problems if discharged. This step often combines physical, chemical, and biological processes to achieve consistent results.

- Facilities aiming for high-quality reuse often employ membrane filtration or ion exchange technologies, which provide precise control over water purity. You can explore ProChem’s advanced membrane filtration and ion exchange solutions for polishing treated water and achieving reuse-ready standards.

Filtration and Nutrient Removal

Filtration and nutrient removal are critical steps in ensuring that treated water meets environmental and operational standards. After secondary treatment, some fine solids and dissolved substances remain, along with nutrients such as nitrogen and phosphorus that can harm aquatic ecosystems if discharged untreated. Effective filtration and nutrient removal protect surface waters and help facilities comply with regulatory requirements.- Filtration systems remove residual solids and particles from the treated water, ensuring clarity and improving overall water quality. Options range from sand and media filters to advanced membrane systems, which target even the smallest suspended materials.

- Nitrogen removal processes, including nitrification and denitrification, convert ammonia and other nitrogen compounds into harmless nitrogen gas. This step reduces the risk of eutrophication in lakes, rivers, and other surface waters.

- Phosphorus removal is equally important. Specialized treatment steps or chemical dosing help remove phosphorus from wastewater, preventing excessive nutrient loads that can trigger algae blooms and disrupt aquatic ecosystems.

Disinfection and Final Effluent Quality

Disinfection is the final step before treated wastewater is released or reused, ensuring that any remaining harmful organisms are effectively neutralized. This stage is crucial for maintaining water quality and protecting public health, particularly when water enters rivers, lakes, or other surface waters. Sodium hypochlorite is one of the most commonly used disinfectants, providing reliable control of bacteria, viruses, and other microorganisms. Proper dosing and contact time are essential to achieve effective disinfection without leaving excessive residual chemicals in the treated water. Other methods, such as ozonation or ultraviolet treatment, may also be used depending on facility requirements and regulatory standards. Operators monitor disinfection closely, checking both chemical levels and biological indicators to ensure the final effluent meets water quality standards. When performed correctly, disinfection guarantees that treated wastewater is safe for release or reuse, completing the wastewater treatment process and closing the loop on environmental protection.Sludge Treatment – Managing What’s Removed

Sludge treatment is an essential part of the wastewater treatment process, focusing on managing the solids removed during primary and secondary treatment. These solids, often rich in organic and biological material, must be stabilized and reduced in volume to prevent odors, reduce health risks, and enable safe disposal or reuse. The first step in sludge treatment is thickening, which concentrates the solids and separates excess water. This makes subsequent processing more efficient and reduces the load on dewatering equipment. Following thickening, biological processes such as anaerobic digestion break down organic material in the sludge, producing stabilized biological solids and generating biogas as a by-product. This biogas can be captured and converted into renewable energy, helping wastewater treatment plants offset operational costs while supporting sustainability goals. Dewatering systems, including centrifuges or belt presses, further remove water from the stabilized sludge, producing a manageable solid material. The resulting biosolids can be safely handled or reused in applications such as agriculture. Effective sludge treatment ensures that the wastewater treatment plant operates efficiently, reduces environmental impact, and maximizes the value of resources recovered from what was once considered waste.Thickening, Digestion, and Dewatering

After primary and secondary treatment, sludge undergoes further processing to reduce volume and stabilize organic material. Thickening is the first step, concentrating primary sludge and other solids to make subsequent treatment more efficient. By allowing solids to settle and water to be removed, thickening prepares the sludge for digestion without overloading downstream equipment. Digestion, often anaerobic, relies on the growth of specialized organisms to break down organic matter in the sludge. These microorganisms convert complex compounds into simpler substances, reducing odor, stabilizing the material, and producing biogas that can be used as a renewable energy source. Properly managed digestion also ensures that sludge is safe and manageable before final processing. Dewatering follows digestion, removing most of the remaining water from the treated sludge. The resulting material, called biosolids, is easier to handle, transport, and repurpose. Dewatering systems, such as centrifuges or belt presses, maximize solids recovery while minimizing moisture content. Through thickening, digestion, and dewatering, wastewater treatment plants transform sludge into a stabilized, resource-ready form that supports both operational efficiency and environmental sustainability.Waste-to-Energy Opportunities in Modern Treatment Plants

Modern wastewater treatment plants are increasingly turning sludge and biogas into valuable energy, transforming what was once considered waste into a resource. By capturing biogas produced during digestion, treatment plants can generate electricity and heat, offsetting energy costs and reducing reliance on fossil fuels. This approach not only improves the sustainability of the treatment plant but also demonstrates the growing potential of wastewater facilities to contribute to energy efficiency on a global level. Advanced systems can even upgrade biogas to biomethane, which can be injected into natural gas grids or used as vehicle fuel, further extending the energy benefits.Environmental Compliance and Protecting the Surrounding Environment

Maintaining environmental compliance is a critical responsibility for any wastewater treatment plant. Properly treated water protects the surrounding environment, including rivers, lakes, and other water bodies that are part of the local water cycle. Discharging untreated or poorly treated wastewater can disrupt ecosystems, harm aquatic life, and create long-term environmental damage. Operators play a key role in ensuring that effluent consistently meets regulatory standards. Monitoring water quality, maintaining treatment equipment, and adjusting processes as needed helps prevent pollutants from entering natural waterways. Regular testing and reporting also provide transparency and accountability for environmental stewardship.A Practical, Integrated Approach to Wastewater Treatment Programs

Managing a wastewater treatment plant effectively requires a practical, integrated perspective on the entire treatment process. Operators know that each stage, starting from preliminary screening up to sludge management, affects overall water treatment performance. Seeing the system as a cohesive program rather than isolated steps ensures consistent effluent quality and smoother operations.- Holistic monitoring: Observing flow rates, solids separation, and biological activity helps operators identify inefficiencies early, preventing minor issues from impacting the entire treatment process.

- Proactive maintenance: Routine inspections, equipment upkeep, and calibration of sensors and pumps ensure the plant runs reliably and minimizes downtime.

- Data-driven adjustments: Using operational data to optimize aeration, sludge removal, and chemical dosing supports both regulatory compliance and efficient water treatment.

- Professional support: Partnering with experienced service providers for operation and maintenance or periodic evaluation and diagnostics strengthens plant performance and reliability. ProChem’s O&M and PEDI services offer structured support, ensuring your wastewater treatment plant achieves long-term efficiency, compliance, and sustainable results.