What Is a Cushion Tank and How It Works in Industrial Water Systems

When you spend enough time around industrial water systems, you start to see the same issues repeat themselves. Unstable pressure, nuisance valve leaks, noisy pipes, or equipment that just does not last as long as it should. In many of those cases, the root cause is not the pump or the controls. It is how the system handles change. Water expands, temperatures shift, and pressure has to go somewhere.

This is where a cushion tank quietly does its job. It gives the system room to breathe as conditions fluctuate, helping absorb pressure swings before they stress piping, valves, or connected equipment. When sized and applied correctly, it protects the entire system without calling attention to itself. When it is missing or overlooked, operators usually find out the hard way.

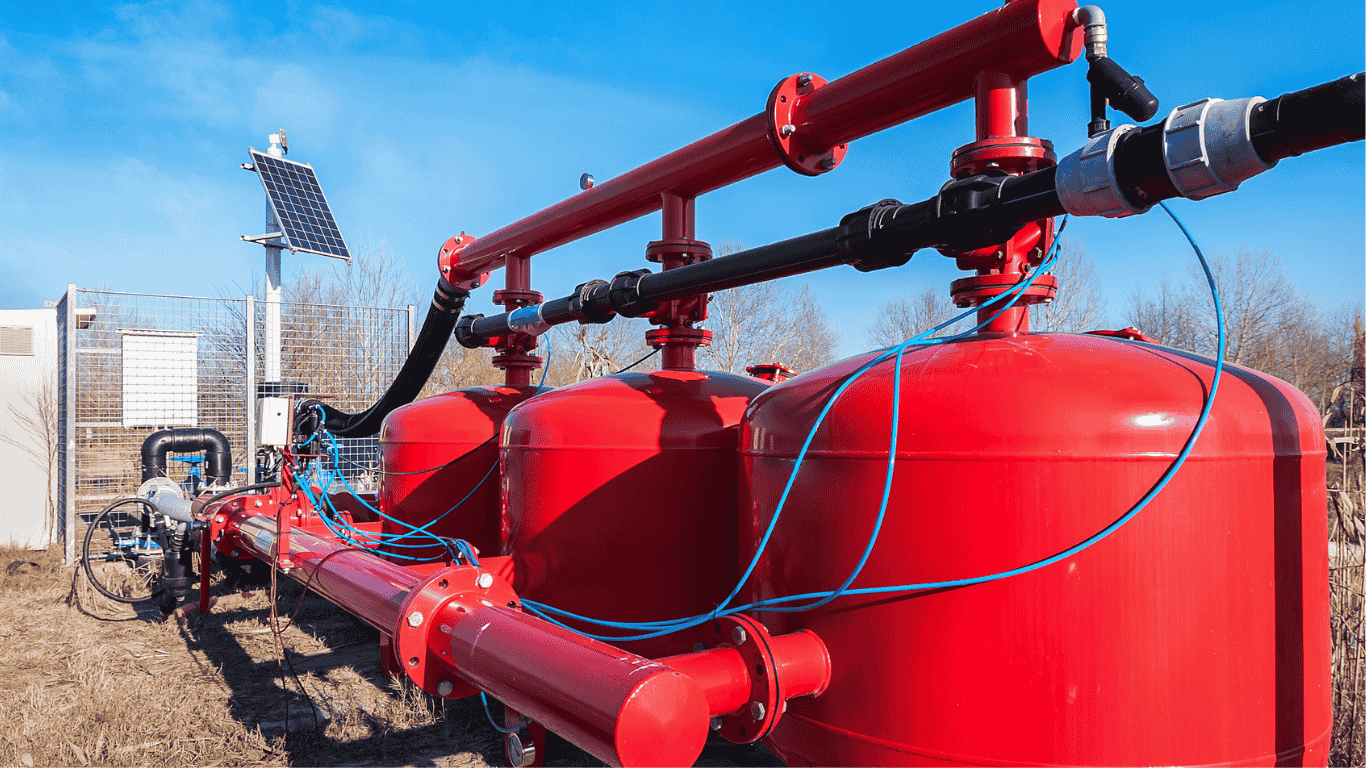

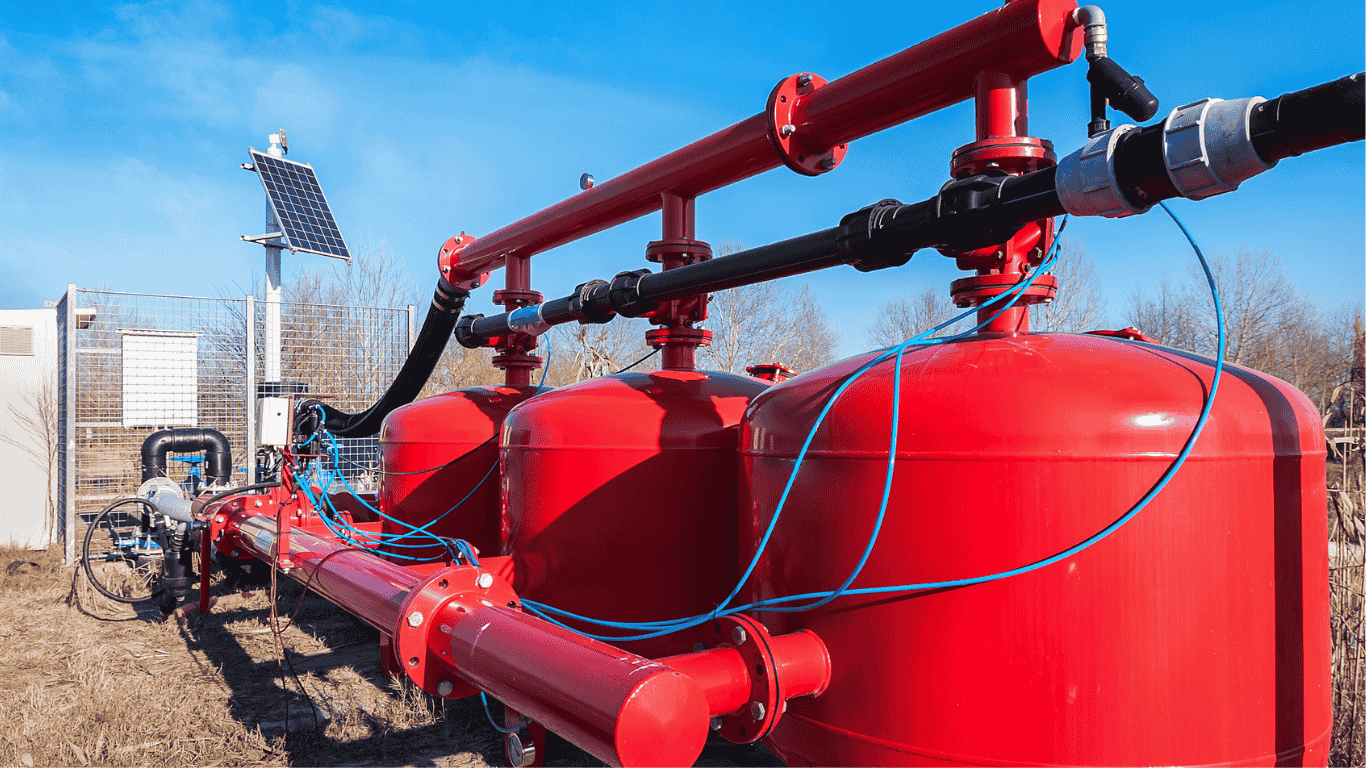

What a Cushion Tank Is and What It Actually Does

At its core, a cushion tank is a pressure-management device. It is installed in a water system to absorb expansion and stabilize conditions as operating demands change. As system water heats up or experiences load shifts, its volume increases. Without somewhere to go, that expansion pushes directly against pipes, valves, and equipment, raising water pressure and stressing the system.

This is why cushion tanks are often grouped with expansion tanks. They serve the same essential purpose, which is to create a controlled space for expansion instead of forcing it into the rest of the system. Inside the tank, an air cushion compresses as water volume increases, allowing the system to adjust smoothly rather than react violently.

When a cushion tank is missing or undersized, operators tend to notice the symptoms quickly. Pressure relief valves weep, pumps cycle more often, and fixtures in potable systems can chatter or bang. These are not random issues. They are clear signs that expansion is happening with nowhere to be safely absorbed.

Thermal Expansion and Pressure Changes Inside Water Systems

Thermal expansion is one of those concepts that sounds simple until you see what it does in the field. As water heats up, its volume increases. In a closed system, that expanded water has no natural place to go. The result is rising pressure that pushes outward on every connected component. Pipes, heat exchangers, pumps, and valves all feel those expansion forces whether they are designed for it or not.

Teams often see the effects first during changes in operating temperature. A system that runs quietly at startup may begin to show pressure changes as it reaches normal load. Gauges creep higher, relief devices activate, or fittings start to seep. Over time, repeated stress like this shortens equipment life and increases the risk of unplanned outages.

Operators usually notice the damage after it has already started. Seals harden, joints loosen, and control components lose reliability. Managing expansion early keeps pressure stable and protects the system from the slow, costly wear that thermal expansion can cause when it is left unchecked.

Key Components Inside a Cushion Tank

Inside a cushion tank, the real work happens where water and air are kept under control. Most tanks are designed with either a bladder or a diaphragm separating the system water from a sealed air or gas space. That separation matters. It allows the tank to manage changing volume without letting air dissolve into the water or migrate through the system.

The air side of the tank is typically pre charged to a specific pressure before installation. That pre charged air compresses as water enters the tank, creating a flexible buffer that absorbs expansion. As system demand changes, the bladder or diaphragm moves back and forth, adjusting smoothly as gallons of water expand and contract.

Failures usually show up when this balance breaks down. A damaged bladder can lose its ability to separate air from water, reducing effective volume and eliminating the cushion effect. Diaphragms can stiffen over time or rupture if operating conditions drift beyond what the tank was designed to handle. When that happens, the tank may still be installed and full of water, but it no longer protects the system the way it should.

Where Cushion Tanks Are Used Across Heating, Cooling, and Potable Systems

Cushion tanks show up in more places than many teams realize. In heating applications, including hydronic heating loops, they manage expansion as water temperatures rise and fall throughout daily operation. Without that buffer, pressure swings can disrupt flow balance and strain components tied to the heating system.

They also play a critical role in a cooling system, where temperature changes still occur even though the goal is heat removal. As loads shift and equipment cycles, expansion and contraction continue to happen. A properly applied cushion tank helps keep the system stable and prevents pressure-related issues that interfere with control and performance.

In potable applications, cushion tanks are commonly installed near a water heater to protect pipes and fixtures from pressure spikes caused by heated water expanding. This is especially important in closed systems with backflow prevention, where pressure has nowhere else to relieve itself. When these tanks are integrated as part of a broader system design, such as those outlined in ProChem’s

treatment system solutions, they support safer operation and help extend the life of connected equipment.

Sizing, Installation, and Operating Conditions to Get Right

Sizing is where many cushion tank problems begin. Tanks range widely in capacity, and choosing the right size is not just about fitting what is available in the mechanical room. It depends on system volume, operating temperature, and how much expansion the system needs to absorb. When a tank is too small, it fills quickly and stops protecting the system, even though it may look fine from the outside.

Installation details matter just as much. We often see tanks installed with the wrong diameter connection, isolated by closed valves, or tied into piping where they cannot respond effectively. In those cases, the tank exists, but it does not function as intended. Over time, that leads to unnecessary stress on pipes and control valves.

Teams should also pay attention to working pressure limits and manufacturer instructions. Tanks should be tested periodically to confirm they are still operating within design conditions. A tank that is installed correctly but operated beyond its limits will fail just as surely as one that was undersized from the start.

How Cushion Tanks Support Long-Term System Control and Reliability

A cushion tank is not a standalone fix. It works best when it is part of a broader approach to system control and reliability. By absorbing expansion and stabilizing pressure, the tank allows other components to operate the way they were designed to. Pumps cycle more predictably, valves seat properly, and controls respond consistently instead of chasing pressure swings.

Over the long term, this stability reduces the risk of premature failure. Systems that manage expansion effectively tend to experience fewer leaks, fewer nuisance shutdowns, and better overall safety. Periodically tested tanks give operators confidence that expansion protection is still in place, even as system conditions evolve.

Water quality plays an important role in maintaining that control. Corrosion, scale, and debris can interfere with valves and sensors, undermining otherwise sound control strategies. Pairing mechanical protection with well-designed chemical programs, such as those described in ProChem’s

chemical program features, helps keep the entire system operating smoothly and reliably.

Supporting System Performance with ProChem’s Services and Expertise

Over the years, we have seen that cushion tanks perform best when they are supported by consistent oversight and practical system knowledge. At ProChem, our services are built around helping customers understand how each component fits into the bigger picture, not just how a single product functions. That perspective allows teams to spot issues early and apply the right solution before small problems turn into larger ones.

We work alongside operators to evaluate how tanks are sized, installed, and used within the system. This often includes reviewing operating conditions, water quality, and maintenance practices to make sure everything is aligned. When needed, we help facilities meet performance goals through ongoing support rather than one-time fixes.

If you are looking for a more structured approach, our

operations and maintenance services focus on protecting equipment, improving reliability, and supporting long-term system performance without unnecessary complexity.

Practical Steps Operators Can Take to Avoid Cushion Tank Issues

Operators can prevent most cushion tank problems by staying observant and proactive. Regularly inspect the tank and surrounding piping for leaks, corrosion, or isolation valves that may have been left closed. Pay attention to system pressure trends during startup and normal operation. Sudden spikes or frequent fluctuations often signal that expansion is no longer under control. Do not ignore noise. Banging, hissing, or vibration near the tank or valves is usually an early warning that water expansion is stressing the system.

When cushion tanks are undersized or overlooked, the entire system feels it. If you want to confirm that your expansion protection is aligned with current operating demands,

connect with our experts for guidance grounded in real-world system performance.

Frequently Asked Questions (FAQs)

How are expansion tanks designed to manage pressure in water systems?

Expansion tanks are designed to absorb the extra volume created when water heats up and expands. By providing a controlled space for that expanded water, they help cancel pressure spikes that would otherwise push into pipes, valves, and fixtures. This design keeps pressure within a manageable range and protects connected equipment from unnecessary stress.

Are cushion tanks required in potable water systems?

In many potable water systems, cushion tanks are strongly recommended, especially when backflow prevention devices create a closed system. Without a tank, pressure can rise quickly when water is heated, leading to issues at the faucet, such as banging or intermittent flow. While requirements vary by location in the USA, most systems benefit from having expansion protection in place.

How do I know how many gallons my system needs?

The gallons needed depend on total system volume, operating temperature range, and allowable pressure limits. Small tanks may seem adequate at first, but they often fill too quickly and stop providing effective expansion control. Reviewing system conditions before installation helps ensure expectations align with real operating demands.

What should be checked before installing or replacing a cushion tank?

Before installation, teams should review prior system performance, pressure readings, and any history of relief valve discharge or leaks. Confirm that the tank size, working pressure rating, and connection points match the system. Tanks should also meet tested industry standards to ensure long-term reliability.

Is it worth the money to upgrade or replace an older tank?

From a reliability standpoint, replacing a failing or undersized tank is often a smart investment. The cost to buy and install the right tank is usually far less than the expense of repairing pressure-related damage or dealing with unexpected downtime. Setting clear expectations around system performance helps guide better decisions and avoid recurring issues.