Efficient Solutions in the Wastewater Treatment Process

Every day, facilities generate wastewater that carries more than just used water. It contains solids, organic material, chemicals, and pollutants that can impact equipment, people, and the surrounding environment if left unmanaged. The wastewater treatment process exists to control those risks and to ensure water is handled responsibly before it is released, reused, or returned to the natural system.

At its core, wastewater treatment is about protecting water quality while keeping operations stable and compliant. When treatment steps work together as intended, they reduce environmental impact, support regulatory requirements, and help facilities operate more efficiently over the long term. In this guide, we'll walk through how wastewater moves through a treatment system, from the first point of entry to final discharge. Each stage plays a specific role, and understanding how they connect makes it easier to identify issues early, improve performance, and make informed decisions about system design and operation.What Is Industrial Wastewater and Why It Requires Treatment

Industrial wastewater is the by-product of everyday operations across manufacturing, food processing, power generation, and chemical production. Unlike domestic sewage, this wastewater can vary widely in temperature, flow, and composition depending on the process that created it. One shift change, a new raw material, or a cleaning cycle can quickly change what is entering the system. This water often carries a mix of suspended solids, oils, chemicals, and other pollutants that cannot be discharged safely without treatment. If left untreated, these materials can damage downstream equipment, disrupt biological activity, and degrade water quality in rivers, lakes, and other receiving bodies. Operators usually see the early warning signs first, unusual odors, excessive foaming, or solids settling where they should not. Proper wastewater treatment addresses these risks by removing contaminants in a controlled, predictable way. It protects infrastructure, helps facilities meet discharge limits, and reduces the environmental impact of industrial waste. More importantly, it gives operators consistency, which is critical when process conditions change and systems are pushed to perform every day.Preliminary Treatment – Protecting the Treatment Plant

Preliminary treatment is the first stage where incoming wastewater is physically controlled before it reaches the core of the treatment plant. The goal here is simple but critical, protect downstream equipment and create stable conditions for every step that follows. When this stage is overlooked or undersized, operators usually feel the impact quickly through clogged lines, damaged pumps, or inconsistent flow. At this point, wastewater passes through screening equipment designed to remove large solid materials such as rags, plastics, wood, and debris. These items do not break down and can cause serious mechanical issues if they move deeper into the system. Floating grease and oils are also separated early, reducing buildup in pipes and tanks and helping maintain consistent hydraulic performance. Well-designed preliminary treatment depends on selecting the right headworks layout and system capacity for real operating conditions. Facilities that invest in properly configured treatment systems are better equipped to handle flow variation and debris loading without disruption, ensuring this first stage consistently protects downstream processes and equipment.Screening and Grit Removal Equipment

The effectiveness of screening equipment goes beyond simply catching debris. The type, spacing, and maintenance of screens directly influence how smoothly the rest of the system operates. When screenings are inconsistent or overloaded, downstream tanks and pumps tend to absorb the stress, leading to uneven flow and higher wear on mechanical components. After larger debris is removed, grit removal focuses on dense materials such as sand and small inorganic particles that settle quickly. These materials may seem harmless, but over time they erode pumps, valves, and piping. Grit chambers are designed to slow the water just enough to separate these heavy particles without allowing organic material to settle with them. When grit removal is undersized or poorly tuned, operators often see buildup in tanks and reduced hydraulic capacity. Grease removal also plays a role at this stage, especially in industrial systems with variable loading. Oils and grease that are not separated early can coat surfaces and interfere with flow distribution. By selecting the right screening and grit removal equipment, facilities reduce mechanical strain, improve reliability, and keep wastewater moving predictably as it is pumped to the next treatment stages.Primary Treatment – Slowing the Water to Let Solids Settle

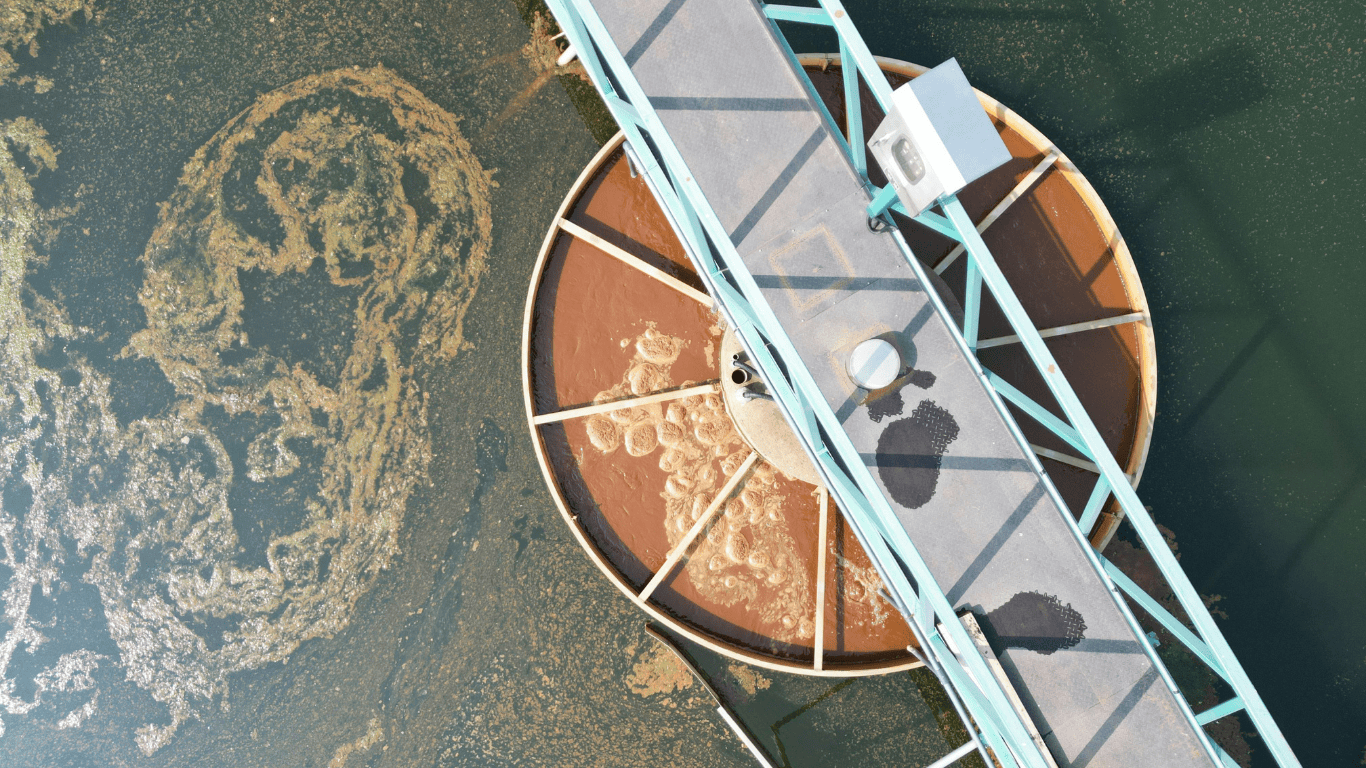

Primary treatment is where the wastewater treatment process begins to rely on time and gravity rather than mechanical separation alone. After preliminary steps, wastewater enters the primary treatment stage and is directed into a settling tank designed to slow the flow. As water slows, heavier solids naturally sink to the bottom while lighter materials move to the surface, creating clear separation zones within the tank. This stage is especially effective at removing suspended solids and a portion of the organic matter that would otherwise place unnecessary load on downstream biological systems. The goal is not to remove everything, but to take out what can be separated easily and efficiently. When primary settling is working properly, it creates more consistent conditions for secondary treatment and reduces energy demand later in the process. Operators often notice the impact of primary treatment in how stable the system feels day to day. Poor settling leads to solids carryover, while well-managed tanks deliver predictable performance. Maintaining proper detention time, sludge removal rates, and flow balance ensures that solids are captured where they belong, setting up the rest of the treatment process for success.Primary Settling Tanks and Sludge Collection

Once wastewater enters primary settling tanks, gravity takes over as the main driver of separation. These tanks are designed to create calm, controlled conditions where solids can settle without disruption. Operators rely on this stage to consistently remove material that would otherwise overload downstream processes, so attention to detail here makes a noticeable difference in overall plant stability.- In primary clarifiers, flow is distributed evenly to prevent short-circuiting, allowing heavier particles to sink and form primary sludge at the bottom of the tank. When distribution is uneven, solids tend to escape before they have time to settle.

- The sludge collected in these tanks must be removed at the right rate. If sludge sits too long, it can go septic and float, reducing separation efficiency and creating odors that operators recognize immediately.

- These tanks called settling basins also require routine inspection of scrapers, weirs, and hoppers. Small mechanical issues often show up first as rising sludge blankets or inconsistent effluent quality.

Secondary Treatment – Letting Biology Do the Heavy Lifting

Secondary treatment is where the wastewater treatment process shifts from physical separation to biological work. At this stage, the focus is on removing dissolved and finely suspended organic material that primary treatment cannot capture. Instead of relying on equipment alone, the system uses carefully managed biological processes to stabilize the wastewater before it moves forward. Bacteria and other microorganisms are introduced or encouraged to grow in controlled environments where they can consume organic material as a food source. As these microorganisms grow, they convert waste into new biomass and simpler compounds that are easier to separate from the water. Operators often think of this stage as keeping the biology healthy, because when conditions are right, the system largely takes care of itself. What matters most here is balance. Too little food, oxygen, or mixing slows biological activity, while too much loading can overwhelm the system. Temperature shifts, flow swings, and chemical upsets are usually felt first in secondary treatment. By understanding how these biological systems respond, operators can make small adjustments early and prevent larger disruptions that affect effluent quality and overall plant performance.Aeration Tanks and Activated Sludge Systems

Aeration tanks are the heart of secondary treatment, where wastewater and microorganisms meet under carefully controlled conditions. In these tanks, activated sludge systems use helpful microorganisms to break down organic material, transforming it into biomass that can later be separated from the treated water. Proper operation of these tanks is essential to maintaining a healthy biological population and ensuring the efficiency of the overall treatment process.- Wastewater is thoroughly mixed to keep microorganisms in contact with the organic material they consume. This ensures that the biological processes are consistent and complete, rather than leaving untreated pockets in the tank.

- Air is pumped into the tanks through diffusers or mechanical aerators, supplying oxygen that microorganisms need to thrive. Adequate aeration maintains microbial activity, supports the breakdown of organic matter, and prevents anaerobic conditions that can produce odors.

- Activated sludge, rich in bacteria and other helpful microorganisms, circulates within the tank. Operators monitor the sludge to ensure the right balance of organisms, solids, and oxygen is maintained, allowing the system to handle variable flows and loads without losing efficiency.

Secondary Clarifiers and Biomass Separation

After aeration tanks, treated wastewater flows into secondary clarifiers, where the focus shifts from biological activity to solid-liquid separation. These clarifiers allow biological sludge to settle, separating it from the clearer effluent above. Proper settling ensures that the treated wastewater leaving the system meets quality standards and is ready for further polishing or discharge. Secondary clarifiers are designed to provide enough detention time for solids to settle naturally. As the biological sludge sinks to the bottom, it can be collected and either returned to the aeration tanks to maintain microbial populations or sent to sludge treatment for further processing. Operators watch closely for signs of poor settling, such as floating solids or turbid effluent, which indicate imbalances in the system. By effectively separating biomass, secondary clarifiers protect downstream processes, maintain effluent quality, and support the continuous performance of the wastewater treatment plant. Settling in these tanks is a critical step, turning the biological work from the aeration tanks into a manageable, concentrated form.Tertiary Treatment – Polishing Treated Water

Tertiary treatment is the final stage of the wastewater treatment process, focusing on refining treated water to a level suitable for reuse or safe discharge. While secondary treatment removes most organic material, tertiary treatment targets residual contaminants and ensures the highest water quality. This stage is essential when water must meet stricter standards for industrial reuse, irrigation, or environmental release.- Filtration systems are commonly used to remove remaining suspended solids, fine particles, and microorganisms. Options include sand filters, activated carbon, and advanced membrane systems, each tailored to the specific needs of the facility. Proper filtration ensures that treated water reaches a purified state without leaving unwanted particles behind.

- Nutrient and contaminant removal is another key component, targeting substances like phosphorus and nitrogen that can cause ecological problems if discharged. This step often combines physical, chemical, and biological processes to achieve consistent results.

- Facilities aiming for high-quality reuse often employ membrane filtration or ion exchange technologies, which provide precise control over water purity. You can explore ProChem’s advanced membrane filtration and ion exchange solutions for polishing treated water and achieving reuse-ready standards.

Filtration and Nutrient Removal

Filtration and nutrient removal are critical steps in ensuring that treated water meets environmental and operational standards. After secondary treatment, some fine solids and dissolved substances remain, along with nutrients such as nitrogen and phosphorus that can harm aquatic ecosystems if discharged untreated. Effective filtration and nutrient removal protect surface waters and help facilities comply with regulatory requirements.- Filtration systems remove residual solids and particles from the treated water, ensuring clarity and improving overall water quality. Options range from sand and media filters to advanced membrane systems, which target even the smallest suspended materials.

- Nitrogen removal processes, including nitrification and denitrification, convert ammonia and other nitrogen compounds into harmless nitrogen gas. This step reduces the risk of eutrophication in lakes, rivers, and other surface waters.

- Phosphorus removal is equally important. Specialized treatment steps or chemical dosing help remove phosphorus from wastewater, preventing excessive nutrient loads that can trigger algae blooms and disrupt aquatic ecosystems.

Disinfection and Final Effluent Quality

Disinfection is the final step before treated wastewater is released or reused, ensuring that any remaining harmful organisms are effectively neutralized. This stage is crucial for maintaining water quality and protecting public health, particularly when water enters rivers, lakes, or other surface waters. Sodium hypochlorite is one of the most commonly used disinfectants, providing reliable control of bacteria, viruses, and other microorganisms. Proper dosing and contact time are essential to achieve effective disinfection without leaving excessive residual chemicals in the treated water. Other methods, such as ozonation or ultraviolet treatment, may also be used depending on facility requirements and regulatory standards. Operators monitor disinfection closely, checking both chemical levels and biological indicators to ensure the final effluent meets water quality standards. When performed correctly, disinfection guarantees that treated wastewater is safe for release or reuse, completing the wastewater treatment process and closing the loop on environmental protection.Sludge Treatment – Managing What’s Removed

Sludge treatment is an essential part of the wastewater treatment process, focusing on managing the solids removed during primary and secondary treatment. These solids, often rich in organic and biological material, must be stabilized and reduced in volume to prevent odors, reduce health risks, and enable safe disposal or reuse. The first step in sludge treatment is thickening, which concentrates the solids and separates excess water. This makes subsequent processing more efficient and reduces the load on dewatering equipment. Following thickening, biological processes such as anaerobic digestion break down organic material in the sludge, producing stabilized biological solids and generating biogas as a by-product. This biogas can be captured and converted into renewable energy, helping wastewater treatment plants offset operational costs while supporting sustainability goals. Dewatering systems, including centrifuges or belt presses, further remove water from the stabilized sludge, producing a manageable solid material. The resulting biosolids can be safely handled or reused in applications such as agriculture. Effective sludge treatment ensures that the wastewater treatment plant operates efficiently, reduces environmental impact, and maximizes the value of resources recovered from what was once considered waste.Thickening, Digestion, and Dewatering

After primary and secondary treatment, sludge undergoes further processing to reduce volume and stabilize organic material. Thickening is the first step, concentrating primary sludge and other solids to make subsequent treatment more efficient. By allowing solids to settle and water to be removed, thickening prepares the sludge for digestion without overloading downstream equipment. Digestion, often anaerobic, relies on the growth of specialized organisms to break down organic matter in the sludge. These microorganisms convert complex compounds into simpler substances, reducing odor, stabilizing the material, and producing biogas that can be used as a renewable energy source. Properly managed digestion also ensures that sludge is safe and manageable before final processing. Dewatering follows digestion, removing most of the remaining water from the treated sludge. The resulting material, called biosolids, is easier to handle, transport, and repurpose. Dewatering systems, such as centrifuges or belt presses, maximize solids recovery while minimizing moisture content. Through thickening, digestion, and dewatering, wastewater treatment plants transform sludge into a stabilized, resource-ready form that supports both operational efficiency and environmental sustainability.Waste-to-Energy Opportunities in Modern Treatment Plants

Modern wastewater treatment plants are increasingly turning sludge and biogas into valuable energy, transforming what was once considered waste into a resource. By capturing biogas produced during digestion, treatment plants can generate electricity and heat, offsetting energy costs and reducing reliance on fossil fuels. This approach not only improves the sustainability of the treatment plant but also demonstrates the growing potential of wastewater facilities to contribute to energy efficiency on a global level. Advanced systems can even upgrade biogas to biomethane, which can be injected into natural gas grids or used as vehicle fuel, further extending the energy benefits.Environmental Compliance and Protecting the Surrounding Environment

Maintaining environmental compliance is a critical responsibility for any wastewater treatment plant. Properly treated water protects the surrounding environment, including rivers, lakes, and other water bodies that are part of the local water cycle. Discharging untreated or poorly treated wastewater can disrupt ecosystems, harm aquatic life, and create long-term environmental damage. Operators play a key role in ensuring that effluent consistently meets regulatory standards. Monitoring water quality, maintaining treatment equipment, and adjusting processes as needed helps prevent pollutants from entering natural waterways. Regular testing and reporting also provide transparency and accountability for environmental stewardship.A Practical, Integrated Approach to Wastewater Treatment Programs

Managing a wastewater treatment plant effectively requires a practical, integrated perspective on the entire treatment process. Operators know that each stage, starting from preliminary screening up to sludge management, affects overall water treatment performance. Seeing the system as a cohesive program rather than isolated steps ensures consistent effluent quality and smoother operations.- Holistic monitoring: Observing flow rates, solids separation, and biological activity helps operators identify inefficiencies early, preventing minor issues from impacting the entire treatment process.

- Proactive maintenance: Routine inspections, equipment upkeep, and calibration of sensors and pumps ensure the plant runs reliably and minimizes downtime.

- Data-driven adjustments: Using operational data to optimize aeration, sludge removal, and chemical dosing supports both regulatory compliance and efficient water treatment.

- Professional support: Partnering with experienced service providers for operation and maintenance or periodic evaluation and diagnostics strengthens plant performance and reliability. ProChem’s O&M and PEDI services offer structured support, ensuring your wastewater treatment plant achieves long-term efficiency, compliance, and sustainable results.