Selecting an Industrial Reverse Osmosis System

Water is one of the most critical resources in industrial operations, and managing its quality can make or break production efficiency. An industrial reverse osmosis system provides a reliable solution, turning raw water into purified water that meets the demanding needs of heavy industry. These reverse osmosis systems are engineered for continuous, large-scale operation, offering industrial water solutions that protect equipment, reduce downtime, and maintain consistent product quality across power plants, automotive facilities, and wood processing operations.

In this article, we’ll guide you through the key aspects of industrial reverse osmosis systems, from understanding how reverse osmosis systems work to selecting the right system size and maintaining peak performance. You’ll discover practical insights on industrial water solutions that help facilities remove dissolved solids, optimize water use, and ensure reliable operations, all while reducing costs and extending the life of critical equipment.What is an Industrial Reverse Osmosis System?

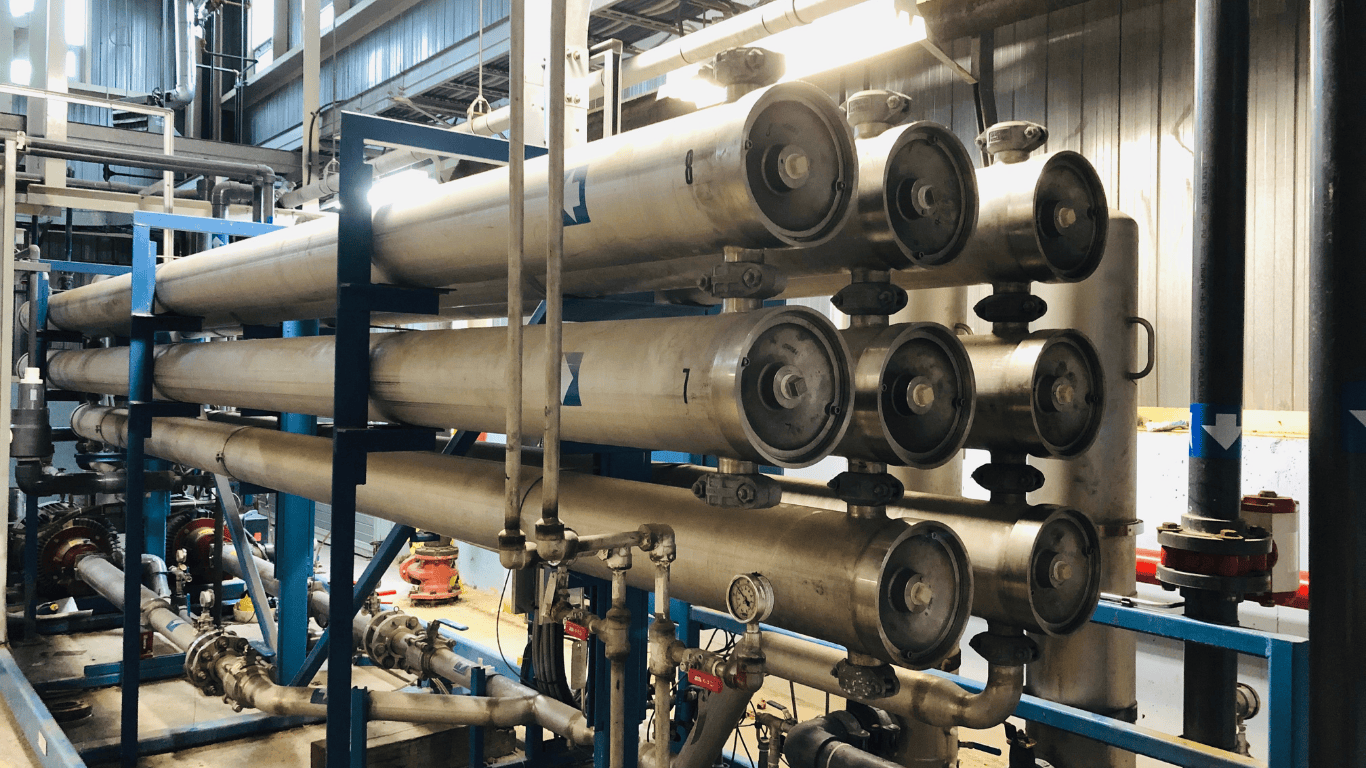

An industrial reverse osmosis system is a high-capacity water treatment solution designed to deliver purified water for demanding industrial applications. Unlike a commercial reverse osmosis system, which is suited for smaller-scale or light commercial use, industrial RO systems are built for continuous operation, handling large volumes of feed water while removing dissolved solids and other contaminants through advanced semi permeable membrane technology. These systems are essential for industries like power generation, automotive manufacturing, and wood processing, where consistent water quality directly impacts equipment performance and product standards. Key features and benefits of industrial RO systems include:- Continuous large-scale operation: Industrial RO systems are engineered with robust pumps and multiple membrane trains to maintain steady performance under heavy-duty conditions, unlike smaller commercial reverse osmosis systems.

- Effective TDS reduction: These systems can lower total dissolved solids (TDS) from over 1,000 ppm to less than 10 ppm, producing high-purity water that protects critical equipment and industrial processes.

- Advanced semi permeable membranes: The heart of the system, membranes selectively allow water molecules to pass while blocking contaminants, ensuring reliable water treatment at industrial scale.

- Industrial water solutions for diverse applications: By delivering clean, low-TDS water, these systems support processes in power plants, automotive production, and wood treatment operations, improving efficiency, product quality, and regulatory compliance.

- Operational reliability and longevity: Industrial RO systems are designed to handle fluctuating feed water quality and continuous production demands, minimizing downtime and maintenance while maximizing system life.

How Industrial RO Systems Work

Industrial reverse osmosis systems purify water by using pressure to force feed water through semi permeable membranes, separating dissolved solids and other impurities from clean water. This osmosis system is designed for continuous, large-scale industrial operation, ensuring high-purity water while protecting critical equipment and supporting consistent process performance.- Pressure-driven filtration: Applying pressure pushes water molecules through the membrane surface while dissolved solids are left behind, producing purified water for industrial applications.

- Cross-flow design: Part of the feed water flows along the membrane surface, carrying away concentrated impurities to prevent fouling and maintain system efficiency.

- Multi-stage configuration: Several pressure vessels arranged in series allow the system to achieve high water recovery rates and consistent quality across large volumes.

- Automated controls and monitoring: Sensors track feed water, flow rates, and system pressure, while PLCs adjust pumps and valves, trigger cleaning cycles, and alert operators to potential issues.

- Optimized performance: Regular monitoring and control help maintain membrane life, reduce energy consumption, and ensure the osmosis system delivers reliable water for industrial operations.

Key Industrial Applications

Industrial reverse osmosis systems are essential across multiple industrial applications, providing high purity water that supports critical processes while protecting equipment and maintaining consistent water quality. Operators in heavy industry rely on these systems to reduce dissolved solids, improve efficiency, and ensure compliance with internal and regulatory standards.- Power Generation and Boiler Feed Water:

- RO-treated water removes scale-forming minerals like calcium, magnesium, and silica, protecting high-pressure boilers and turbines from corrosion and fouling.

- Large-scale facilities often operate 500–5,000 GPM systems to meet continuous steam generation demands, with recovery rates of 75–85% helping minimize freshwater use.

- Operators should regularly monitor feed water TDS and check for early signs of scaling; adjusting pretreatment chemicals can prevent costly downtime and efficiency losses.

- Automotive Manufacturing Processes:

- Automotive plants rely on industrial RO systems for paint booth operations, parts washing, and engine cooling, where even minor variations in water quality can impact product quality.

- Purified water prevents paint defects, water spotting on finished components, and corrosion in cooling systems, supporting high manufacturing standards.

- Operators often catch early issues by monitoring flow rates and conductivity, ensuring consistent water quality across production shifts.

- Wood Processing and Treatment Operations:

- Pulp, paper, and engineered wood facilities use RO systems to maintain consistent chemical reactions during bleaching, adhesive curing, and kiln drying, improving product uniformity and reducing chemical consumption.

- High-purity water ensures even penetration of preservatives and minimizes mineral deposits that can compromise wood surface quality.

- Advisory tip: Regularly verify system pressure and conduct water quality tests to prevent fouling and optimize membrane life.

- Additional Industrial Water Solutions:

- Across these sectors, industrial RO systems allow facilities to recycle treated water, reduce environmental discharge, and improve operational efficiency.

- Teams should review membrane performance trends, adjust cleaning protocols, and plan for peak demand to maintain continuous operation and minimize maintenance interruptions.

System Sizing and Capacity Planning

Choosing the right industrial reverse osmosis system begins with understanding your facility’s water needs. Proper sizing ensures consistent water quality, protects equipment, and avoids unnecessary energy or chemical costs. Operators should consider not just current demands but also peak flow, recovery rate, and potential future expansion when planning system capacity.- Assessing Process Demands and Feed Water:

- Evaluate the volume and quality of feed water for each industrial application, including variations in total dissolved solids and potential contaminants.

- Review peak flow requirements during production surges, ensuring the RO system can handle maximum demand without sacrificing water quality or system performance.

- Advisory tip: Monitor feed water trends regularly, as seasonal or operational changes can affect sizing decisions and membrane performance.

- Typical Capacities and Recovery Rates:

- Industrial RO systems range from 100–10,000+ GPM, depending on application scale—from automotive manufacturing lines to power generation boilers.

- Incorporate 20–30% excess capacity to accommodate maintenance, future growth, or temporary surges in water demand.

- Recovery rates of 75–85% are common, balancing efficient freshwater use with safe concentrate handling and disposal.

- Practical Tips for Matching Production Requirements:

- For facilities with multiple production lines, consider parallel membrane trains to provide flexibility and uninterrupted water supply.

- Factor in system downtime for cleaning or membrane replacement, and plan capacities so production continues smoothly during maintenance cycles.

- Operators often improve reliability by integrating automated controls that adjust flow rates based on real-time demand, maintaining both efficiency and consistent water quality.

Components and Design Considerations

A high-performing industrial reverse osmosis system relies on well-engineered components working together seamlessly. Understanding each part helps operators maintain reliability, extend membrane life, and optimize water quality. These systems combine advanced water treatment equipment, membrane technology, and automation to handle demanding industrial applications.- Pretreatment Systems:

- Pretreatment protects membranes by removing suspended solids, hardness, chlorine, and other contaminants before water reaches the RO system.

- Common filtration techniques include multimedia filters, water softeners, and antiscalant dosing to prevent scaling and fouling.

- Advisory tip: Regular monitoring of pretreatment performance prevents early membrane degradation and keeps recovery rates high.

- Membranes, Pumps, and Cleaning Systems:

- Membrane arrays form the core of industrial RO systems, with parallel configurations in membrane systems providing redundancy for continuous operation.

- High-pressure pumps deliver consistent feed water pressure, critical for optimal reverse osmosis performance.

- Clean-in-place (CIP) chemical programs maintain membrane efficiency by removing scale, biofilm, and other fouling, extending service life without disassembling the system.

- Materials and Vessel Design:

- Pressure vessels are typically stainless steel or fiberglass to withstand industrial operating pressures and corrosive feed water.

- Multi-stage membrane systems are arranged to maximize recovery while protecting membranes from concentrated dissolved solids.

- Selecting the right vessel material ensures durability and reduces long-term maintenance costs.

- Automation and Monitoring:

- Modern RO systems integrate PLC-based controls for real-time monitoring of flow rates, pressure, and water quality parameters.

- Automated alarms and performance tracking help operators catch issues early, reducing downtime and protecting sensitive equipment.

- For a deeper look at industrial RO system features, see ProChem’s system solutions and features.

Performance Optimization and Monitoring

Maintaining optimal performance in an industrial reverse osmosis system requires continuous attention to water quality and proactive management of membranes and chemicals. Operators who actively monitor system conditions can prevent downtime, extend membrane life, and ensure consistent removal of impurities.- Monitoring Critical Parameters:

- Track feed pressure, permeate flow, and conductivity to detect shifts in water quality that may indicate membrane fouling or scaling.

- Small fluctuations often signal issues early, allowing teams to take corrective action before production is impacted.

- Advisory note: Regular checks help maintain target recovery rates while protecting downstream equipment.

- Data-Driven Cleaning and Energy Recovery:

- Schedule chemical cleaning cycles based on system performance data rather than fixed intervals to maximize membrane life and reduce chemical use.

- Energy recovery devices capture pressure from the concentrate stream, lowering operating costs, particularly in high-pressure or high-TDS applications.

- Operators often catch efficiency losses by comparing historical performance trends and adjusting chemical dosing or flow rates accordingly.

- Regular Membrane Analysis:

- Periodic membrane autopsy and inspection reveal early signs of fouling, scaling, or biological growth, preventing unexpected downtime.

- Addressing minor issues promptly ensures consistent water quality and reduces long-term repair costs.

- For detailed guidance, see our system performance and maintenance blog.