How Water Treatment Chemicals Protect Water Systems

When people think about modern water systems, automation and advanced equipment usually come to mind first. In practice, chemistry still does much of the heavy lifting. Water enters a system carrying dissolved minerals, suspended solids, microorganisms, and gases that can quietly interfere with performance if they are left unmanaged. Even the most sophisticated treatment equipment relies on the right chemical support to function as intended.

Water treatment chemicals help stabilize water before it moves through a system, during active treatment, and as it circulates through piping and equipment. They support consistent operation, protect assets, and help teams avoid issues that tend to show up slowly, such as corrosion, scale, or biological growth. From intake to discharge, these chemicals play a critical role in keeping water predictable and controllable. In this article, we want to share how these tools fit into real-world operations and why a practical, chemistry-first mindset still matters for long-term system reliability.How Water Treatment Chemicals Support Modern Water Systems

In day-to-day operations, water treatment rarely happens at just one point. It is a continuous process that starts before water ever reaches a piece of equipment and continues as that water moves through the facility. Chemicals are used upstream to condition incoming water, helping stabilize pH, control solids, and reduce the load placed on filters and membranes. Downstream, they help maintain consistency, protect surfaces, and support discharge or reuse requirements. Operators see this firsthand. When the chemistry is right, systems run smoothly and adjustments stay predictable. When it is off, even slightly, small issues begin to compound. Pumps work harder, heat transfer drops, and maintenance teams start chasing symptoms instead of causes. That is why chemical treatment should be viewed as part of the core operating strategy, not a secondary add-on. Across industrial and commercial systems, water treatment chemicals support reliable operations by keeping the treatment process balanced from start to finish. They help facilities manage variability in source water, respond to seasonal changes, and maintain control as demand shifts. When chemistry is integrated into the overall process, teams gain more stability, fewer surprises, and better long-term performance from the systems they rely on every day.Coagulation and Solids Removal in Treatment Processes

One of the most common challenges teams face in water and wastewater treatment is dealing with fine particles that refuse to settle on their own. These solids are often too small or too stable to separate naturally, which is where coagulation becomes essential. Without proper chemical support, clarification tanks struggle, filtration loads increase, and downstream equipment sees unnecessary wear. Getting this step right sets the tone for the entire treatment process. During effective coagulation and solids removal, several things should happen in sequence:- Fine suspended solids lose their electrical charge, allowing them to collide and form larger, heavier particles. Chemicals such as ferric chloride, aluminum sulfate, and ferric sulfate are commonly used to initiate this process and promote reliable particle growth.

- As these particles grow, precipitation and sedimentation take over. The newly formed floc begins to settle out of the water, separating clean water from solids that would otherwise remain suspended.

- When settling is incomplete, solids carry over and create excess sludge downstream. Operators often notice cloudy effluent, rising sludge volumes, or overloaded filters, all signs that coagulation chemistry may be off.

pH Adjustment and Chemical Balance Control

pH is one of those measurements operators check every day, yet it is often underestimated until something goes wrong. Water that drifts too far in either direction can quietly undermine treatment performance, accelerate corrosion, or interfere with downstream processes. Effective pH adjustment is less about chasing a number and more about maintaining chemical balance across the system. In practice, pH control relies on a careful blend of acids and alkaline materials, selected based on how the water behaves over time. Hydrochloric acid and sulfuric acid are commonly used to bring high pH levels back into range, while sodium hydroxide, soda ash, and calcium hydroxide are applied to raise pH when water becomes too acidic. Each option behaves differently once introduced, especially as it reacts with dissolved salts and existing chemistry in the water. Operators often run into trouble when corrections are too aggressive. Overfeeding can swing pH rapidly, creating instability that affects coagulation, disinfection, and even biological activity. It also increases the risks associated with handling highly corrosive materials, both for personnel and for piping and equipment. A steady, measured approach tends to deliver better results. Monitoring trends, understanding buffering capacity, and making incremental adjustments help teams maintain reliable pH control while protecting the integrity of the overall treatment process.Disinfection and Microbial Control Strategies

Disinfection is where water treatment becomes personal. This is the step that protects people, products, and processes from harmful bacteria and biological growth. At the same time, it is one of the areas where chemistry choices have the most visible consequences, from byproducts in the water to impacts on taste, odor, and equipment compatibility. Most disinfection strategies rely on oxidizers, each with its own strengths and tradeoffs. Sodium hypochlorite remains widely used because it delivers reliable chlorine residuals and is effective across many applications. Chlorine dioxide offers strong microbial control with fewer chlorinated byproducts, making it attractive in systems where taste and odor are a concern. Hydrogen peroxide provides oxidation without leaving a lasting residual, breaking down into oxygen and water, which appeals to facilities focused on minimizing chemical carryover. Ozone delivers rapid disinfection and strong oxidation, though it requires careful system design and on-site generation. Operators should think beyond kill rates alone. Byproducts, material compatibility, and the way each oxidizer behaves in a specific system all matter. Some chemicals interact aggressively with metals or elastomers, while others demand tighter control to remain effective. The goal is to disinfect water consistently without creating new problems downstream. Choosing the right disinfection approach starts with understanding the system, the water chemistry, and the level of control the operation can realistically maintain.Managing Scale, Corrosion, and Equipment Protection

Operators often notice scale and corrosion long before a report confirms it. A rise in energy use, uneven heat transfer, reddish staining, or frequent valve issues are usually early signs that water chemistry is starting to work against the system. Left unchecked, these problems shorten equipment life and create ongoing maintenance headaches, especially in cooling towers and high-temperature loops. Effective control starts with understanding how scale and corrosion form inside piping and equipment:- Scale develops when dissolved minerals fall out of solution and harden onto surfaces. As layers build up, they insulate heat transfer areas, restrict flow, and force pumps and heat exchangers to work harder than they should.

- Corrosion occurs when water chemistry reacts aggressively with metal surfaces. Iron is particularly vulnerable, and once corrosion starts, it can spread quickly through piping and components.

- Treatment programs often rely on inhibitors and specialty cleaners to interrupt these reactions. Phosphoric acid is commonly used to form protective films, while sulfur-based compounds and targeted cleaners help remove existing deposits without damaging base materials.

Specialized Applications Across Industrial and Food Processing Facilities

Water treatment needs vary widely across industries, and operators quickly learn that a one-size-fits-all approach rarely works. Each facility presents its own chemistry challenges, from the high mineral loads in industrial cooling towers to the strict microbial standards in food processing lines. Understanding how treatment chemicals interact with specific water systems is key to protecting equipment, ensuring product quality, and maintaining regulatory compliance. Here’s how water treatment applications shift depending on the industry:- Industrial facilities often face issues with scale, corrosion, and variable water quality. Operators rely on customized chemical programs to control pH, prevent fouling, and extend equipment life without interrupting operations.

- Food processing plants prioritize biological control and sanitation. Water treatment chemicals are selected not just to disinfect water, but to protect machinery, maintain safe contact surfaces, and minimize any impact on taste or product quality.

- Paper and manufacturing businesses deal with large volumes of water with suspended solids or high dissolved mineral content. Coagulants and dispersants help manage solids and prevent scaling on heat exchangers and pulping equipment.

Membrane Systems and Chemical Cleaning Considerations

Membrane systems are highly effective at filtration, but they are sensitive to the water chemistry they encounter. Operators often find that problems arise not from how often membranes are cleaned, but from whether the correct chemicals are used for the specific fouling type. Choosing the right solution ensures the system performs efficiently and membranes last longer. Key considerations for membrane cleaning and maintenance include:- Identify the fouling type: Scale, biological growth, and organic deposits each respond to different chemical treatments. Using the wrong cleaning solution can reduce effectiveness and potentially damage the membrane.

- Use tailored cleaning solutions: Chemicals should be matched to the membrane material and the type of contaminants. Customized formulations help operators restore performance without introducing new risks.

- Monitor performance during cleaning: Flow rates, pressure drops, and water quality indicators reveal whether the cleaning solution is working as intended. Adjusting concentration or contact time can maximize results.

- Integrate into the overall system strategy: Membrane cleaning should complement ongoing water treatment, not replace it. Proper chemical use reduces downtime and maintains long-term efficiency.

Safety, Handling, and Environmental Responsibility

Working with water treatment chemicals requires careful attention to safety and environmental responsibility. Operators deal with highly corrosive substances like sulfuric acid and hydrochloric acid daily, and proper control measures are essential for protecting personnel, equipment, and the surrounding environment. Following best practices doesn’t just prevent accidents—it ensures consistent water treatment performance and long-term operational stability. Here are key considerations for safe handling and environmental stewardship:- Use appropriate personal protective equipment (PPE): Gloves, goggles, and face shields help protect against splashes or accidental contact when handling corrosive chemicals.

- Implement strict storage and control measures: Segregate acids, bases, and other reactive chemicals. Keep storage areas well-ventilated, clearly labeled, and equipped with spill containment solutions.

- Train personnel regularly: Teams should understand the properties of each chemical, how to respond to incidents, and proper handling procedures. Consistent training reinforces safe practices across the facility.

- Monitor environmental impact: Evaluate discharge and reuse practices to minimize potential harm. Proper chemical dosing and neutralization protect aquatic life and comply with regulations.

- Maintain a reliable supply chain: Having the right chemicals available consistently ensures that safety and treatment goals are not compromised by substitutes or interruptions.

Wastewater Treatment and Chemical Optimization

Effective wastewater treatment relies on how chemicals are applied throughout the process. Properly selected and dosed treatment chemicals improve solids removal, control sludge formation, and ensure compliance with regulatory standards. When operators focus on chemical efficiency, they often see both operational and cost benefits. Key points for optimizing wastewater treatment with chemicals include:- Targeted coagulants and flocculants: Using chemicals like ferric chloride or aluminum sulfate in the right amounts helps suspended solids aggregate, improving sedimentation and reducing the volume of sludge generated.

- Efficient disinfection: Oxidizers such as sodium hypochlorite or hydrogen peroxide disinfect wastewater effectively while minimizing chemical overuse, reducing both costs and residual impacts.

- Monitor and adjust dosing: Flow rates, incoming water quality, and seasonal variations all affect chemical demand. Fine-tuning treatment ensures consistent removal without waste.

- Sludge management: Optimized chemical treatment reduces sludge volume and makes dewatering or disposal more efficient, which lowers operational expenses.

- Compliance and reporting: Correct chemical usage supports meeting discharge regulations and maintaining documentation for inspections, avoiding fines or remediation costs.

Practical Steps for Choosing the Right Water Treatment Chemicals

Selecting the right water treatment chemicals can feel overwhelming, but taking a structured approach helps operators maintain control and prevent many problems before they occur. Here’s a practical checklist to guide decision-making:- Understand your system: Identify the type of water system you’re managing: cooling towers, boilers, or industrial process lines, and note any historical issues like scaling, corrosion, or biological growth.

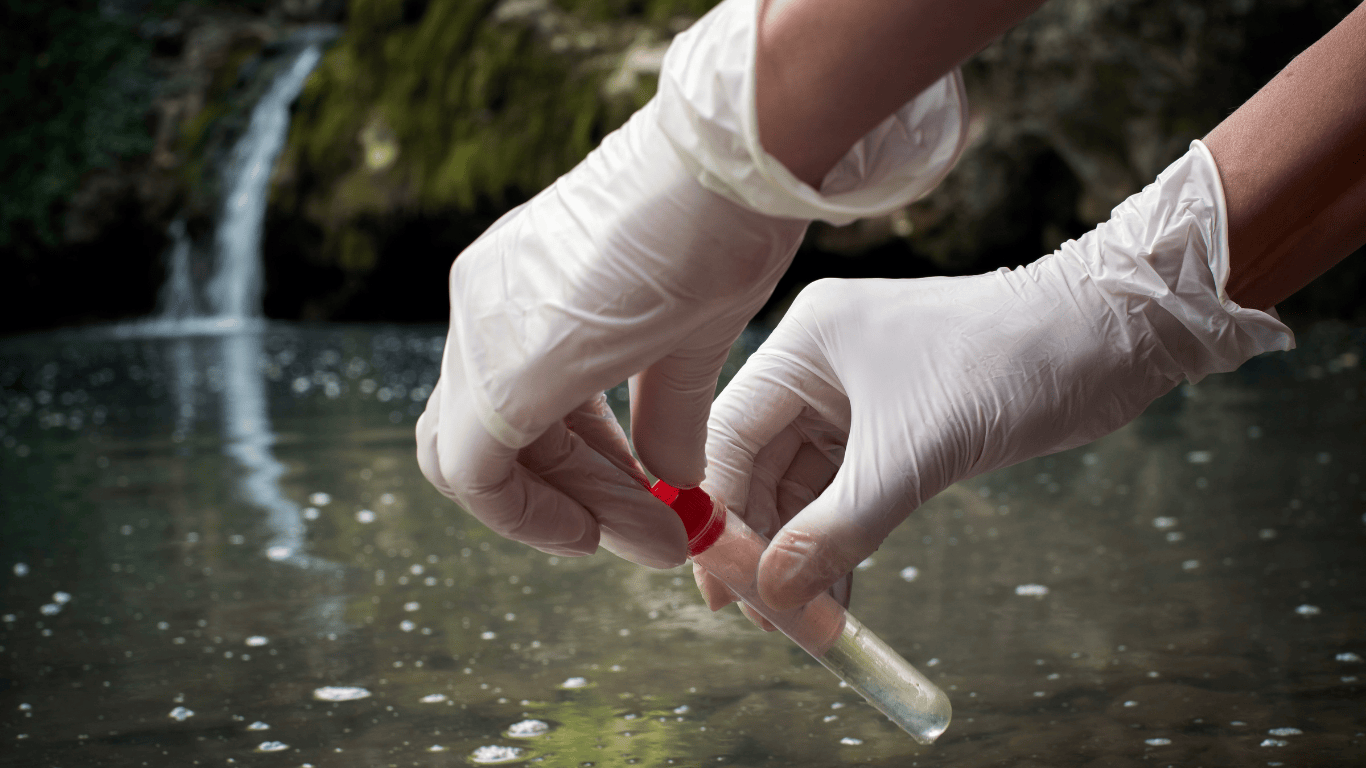

- Assess water quality: Test for pH, hardness, dissolved solids, and microbial load. Knowing the starting point makes it easier to choose chemicals that address the specific challenges in your system.

- Match chemicals to objectives: Consider whether the focus is on disinfection, coagulation, corrosion control, or scale prevention. Each water treatment chemical has unique properties that suit different applications.

- Monitor and adjust: Regularly check chemical dosing and system response. Even the best chemicals are ineffective if they are under- or over-applied.

- Work with experts: Experienced suppliers can help tailor solutions to your system, offer ongoing technical support, and ensure you use chemicals safely and efficiently.

How ProChem Supports Smarter Chemical Programs

Running a water system smoothly often comes down to having the right chemical strategy in place. Operators and facility teams benefit most when treatment chemicals are part of a thoughtful, monitored program rather than a reactive fix. Smarter programs focus on understanding system behavior, anticipating changes in water quality, and adjusting chemistry before issues appear. Here’s what a well-designed chemical program looks like in practice:- System assessment: Specialists evaluate how water moves through piping, equipment, and treatment units to identify potential problem areas and optimize chemical placement.

- Customized solutions: Rather than a generic approach, chemicals are selected and dosed to match the specific conditions, whether it’s controlling scale in cooling towers or managing biological growth in process lines.

- Ongoing monitoring: Regular checks and adjustments help maintain control, prevent unexpected downtime, and extend equipment life.

- Collaboration and support: Operators can rely on guidance from trained specialists who help interpret data, troubleshoot issues, and develop solutions that fit the facility’s unique needs.

Frequently Asked Questions (FAQs)

What is a precursor in water treatment chemicals?

A precursor is a chemical that reacts within a water system to generate an active treatment agent. For example, sodium chlorite serves as a precursor for chlorine dioxide, which is then used for effective disinfection. Understanding precursors allows operators to control dosing accurately and achieve consistent treatment results.How does bleach fit into water treatment applications?

Bleach, commonly supplied as sodium hypochlorite, is widely used for water disinfection and microbial control. Its reliability and ease of application make it common in both municipal and industrial systems, although careful monitoring of concentration is required to maintain water quality and limit taste or odor concerns.Can water treatment chemicals affect taste?

Yes. Certain treatment chemicals can influence water taste if dosing is not properly managed. While disinfectants such as chlorine are essential for safety, maintaining appropriate residual levels ensures effective treatment without creating noticeable off-flavors.Why is iron a concern in water systems?

Iron may enter water systems through source water or internal corrosion. If untreated, it can cause staining, scaling, and interference with filtration or coagulation processes. Targeted treatment chemicals help control iron levels, prevent fouling, and preserve overall system performance.What services should operators expect from a water treatment provider?

A comprehensive water treatment provider offers more than chemical supply. Typical services include system evaluations, chemical selection and dosing guidance, troubleshooting, and ongoing monitoring. These services help operators maintain consistent water quality, reduce maintenance risks, and prevent system issues before they escalate.How Commercial Reverse Osmosis Systems Work

Industrial facilities today face increasing pressure to manage water efficiently. Rising utility costs, stricter environmental regulations, and corporate sustainability goals make it essential to reduce water waste while maintaining consistent operations.

A commercial reverse osmosis system is one of the most effective tools for achieving these objectives. By removing dissolved solids, bacteria, and other contaminants, these systems transform ordinary water into high purity water suitable for multiple industrial applications. Teams often see measurable benefits from integrating RO systems, including significant water cost savings, reduced reliance on municipal supply, and compliance with regulatory standards. In the following sections, we’ll walk you through how these systems work, how they’re designed, and practical tips for maximizing performance in your facility.What is a Commercial Reverse Osmosis System?

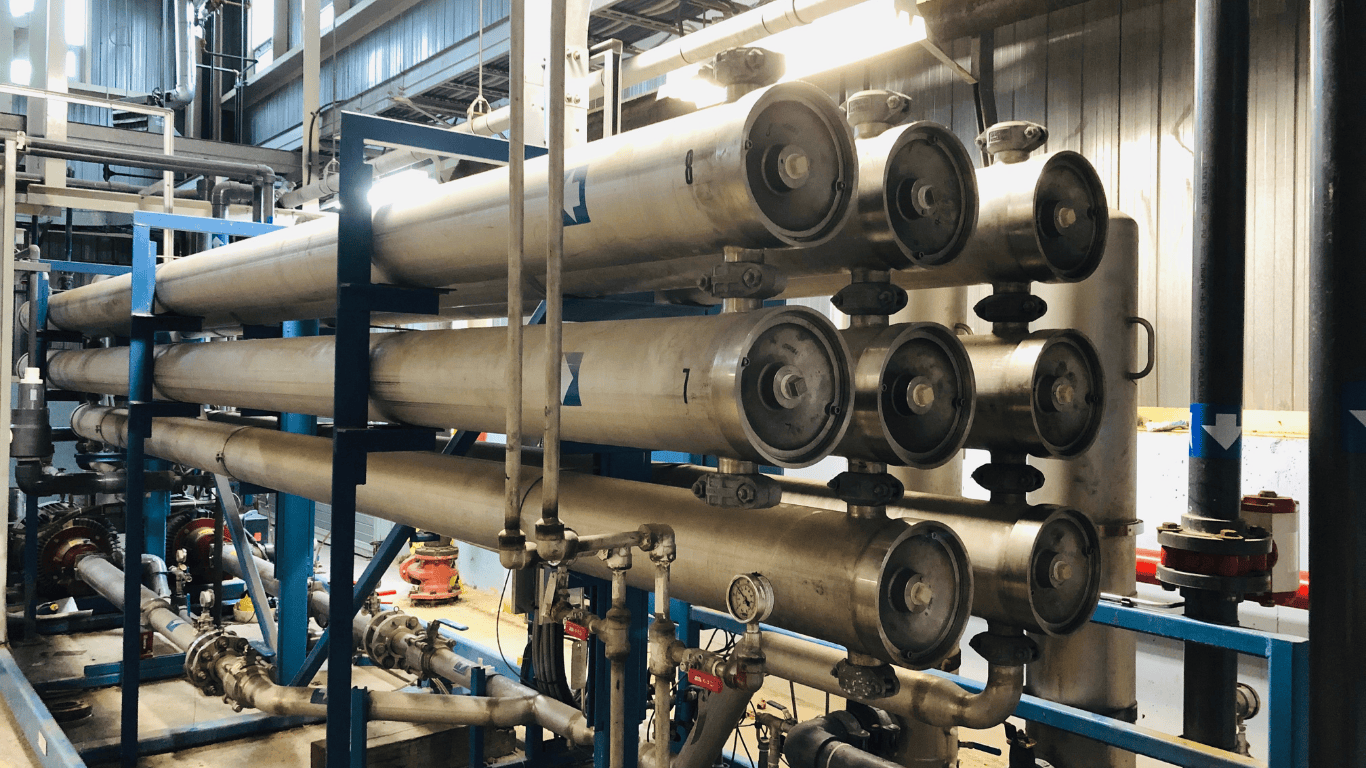

A commercial reverse osmosis system is designed to handle the high demands of industrial and large-scale commercial facilities. Unlike residential units that operate at lower pressures and produce 50–100 gallons per day, commercial RO systems generate pressures of 150–600 PSI and manage flow rates ranging from 1,000 to over 500,000 gallons per day. This allows them to consistently deliver high purity water while removing 95–99% of dissolved solids, bacteria, viruses, and other contaminants. At its core, the reverse osmosis process forces water through semi-permeable membranes with pores as small as 0.0001 microns. Contaminants such as dissolved solids, chlorine, calcium, and organic compounds are rejected, leaving purified water suitable for a variety of industrial applications. Teams often notice that maintaining proper pre-treatment and membrane care is key to keeping performance consistent over time. A typical commercial RO system includes several integrated components working together efficiently:- Pre-treatment units – multimedia filtration and activated carbon to remove suspended solids, chlorine, and organic compounds

- High-pressure pumps – maintain consistent pressure across membrane vessels

- Membrane vessels – spiral-wound or hollow fiber membranes for optimal filtration. Learn more about membrane filtration and system components.

- Post-treatment systems – carbon block filters and optional remineralization depending on application

Industrial Benefits of Commercial RO Systems

Commercial reverse osmosis systems provide significant operational and environmental advantages for industrial facilities. By removing dissolved solids and other contaminants, these systems improve water quality, safeguard critical equipment, and reduce maintenance needs. Reliable RO water helps protect pumps, boilers, and heat exchangers from scaling and corrosion, ensuring process reliability and minimizing downtime. Beyond equipment protection, these systems support water reclamation and sustainability goals. Industrial facilities often achieve 40–80% reductions in fresh water usage, translating to lower water procurement and wastewater disposal costs. Companies benefit from measurable cost savings, while also meeting regulatory requirements and supporting corporate environmental initiatives. The financial and operational benefits make commercial RO systems a sound investment. Many facilities achieve return on investment within 2–3 years through utility savings alone. Predictable water quality also enhances process efficiency, product consistency, and long-term reliability, making RO systems a cornerstone of modern industrial water management strategies.Applications by Industry

Commercial reverse osmosis systems are versatile tools that serve a wide range of industries, from food and beverage production to power generation and advanced manufacturing. These systems provide reliable high purity water while reducing operational costs, protecting equipment, and supporting regulatory compliance. By tailoring design and pre-treatment to each facility’s specific needs, industrial RO systems enable effective water reclamation, consistent process performance, and long-term sustainability. In the following sections, we’ll explore how different industries use RO water to optimize operations, maintain equipment reliability, and improve overall water management.1. Food & Beverage

Food and beverage facilities rely heavily on consistent water quality to ensure product safety and uniformity. A commercial reverse osmosis system delivers high purity RO water that removes dissolved minerals and contaminants, helping maintain taste, appearance, and shelf life across production batches. Coffee shops, beverage manufacturers, and large-scale food processors benefit from clean water that protects equipment and reduces maintenance costs. RO water also supports Clean-in-Place (CIP) systems, lowering chemical usage by 25–40% and preventing scale formation on processing surfaces. In steam generation applications, high purity water prevents corrosion and scaling in boilers, extending equipment life. Teams often find that investing in a commercial RO system ensures reliable water quality, reducing downtime and maintaining consistent product standards in daily operations.2. Pharmaceutical & Healthcare

Pharmaceutical manufacturing and healthcare facilities require purified water that meets strict regulatory standards. Commercial RO systems serve as a key pre-treatment step for Water for Injection (WFI), ensuring high purity water for sensitive processes. Laboratory operations, research facilities, and dialysis units depend on consistent water treatment to protect equipment and maintain accurate results. By removing dissolved solids and other contaminants, RO systems streamline compliance with FDA and cGMP requirements. Operators often notice that well-maintained systems simplify validation, documentation, and regulatory reporting, reducing operational risks while supporting safe, reliable patient care.3. Power Generation & Utilities

Power generation facilities demand large volumes of high-quality water for boiler feed and cooling tower makeup. Industrial applications benefit from commercial RO systems that remove dissolved solids, preventing scaling and corrosion on heat transfer surfaces. Maintaining water quality directly improves energy efficiency, reduces chemical treatment needs, and lowers maintenance costs. Teams often find that integrating RO water treatment into boiler and cooling systems extends equipment life, supports consistent performance, and allows higher cycles of concentration for water reuse, contributing to both cost savings and environmental compliance.4. Manufacturing & Industrial Processes

Industrial reverse osmosis systems support a wide range of manufacturing and processing operations, from electronics and semiconductor production to metal finishing, textile, and chemical processing. By producing high purity water, these systems enable effective water reclamation and metals recovery, reducing environmental impact while lowering operational costs. RO water protects sensitive equipment, ensures process consistency, and supports chemical processing applications where water quality is critical. Operators often see that reliable RO systems allow facilities to recover valuable materials, minimize waste, and maintain regulatory compliance, making them an integral part of modern industrial water management.Commercial RO System Design and Configuration

Designing a commercial reverse osmosis system starts with understanding your facility’s water needs. Proper sizing ensures flow rates meet both average and peak demand, while storage tank capacity helps maintain consistent supply during high-use periods. Teams should watch for variations in source water quality, as these influence pre-treatment requirements and membrane selection. Pre-treatment is critical to protect membranes and optimize system longevity. Multimedia filtration removes suspended solids, and carbon block units eliminate chlorine and organic compounds that could damage membranes. Membrane configuration, typically spiral-wound for commercial systems, determines both performance and maintenance accessibility. Modular designs allow facilities to expand capacity as demand grows, while space-saving system features help retrofit facilities with limited floor space. Recovery rate optimization balances water savings with membrane life and system complexity. High-efficiency pumps and energy recovery devices can reduce operating costs by capturing pressure energy from the concentrate stream. By carefully selecting pre-treatment, membrane type, and system layout, operators can optimize capacity, minimize footprint, and plan for future growth, ensuring the commercial RO system delivers reliable high purity water while supporting operational efficiency over many years.Advanced Technology Features

Modern commercial reverse osmosis systems incorporate advanced technology to improve performance, reliability, and operational efficiency. Variable frequency drives (VFDs) adjust pump speed based on actual demand, reducing energy consumption and mechanical stress while maintaining optimal flow rates. Automated membrane cleaning systems extend membrane life by performing scheduled or demand-based cleaning cycles, minimizing labor while ensuring consistent water quality. Remote monitoring and SCADA integration allow teams to track system performance 24/7, enabling predictive maintenance before small issues affect operation. Alerts and data analytics provide actionable insights on pressure, flow, and recovery rates, helping operators optimize cleaning schedules and chemical dosing. These controls not only enhance reliability but also improve operational safety and reduce the risk of unexpected downtime. Redundant system design further boosts reliability for critical applications. Duplicate pumps, membranes, and control systems ensure uninterrupted operation, while modular layouts allow maintenance on individual components without halting production. By leveraging automated controls, energy-saving technologies, and predictive monitoring, facilities can achieve superior water quality, lower operational costs, and consistent performance across all industrial applications.System Selection, Installation, and Commissioning

Choosing and installing a commercial reverse osmosis system requires careful planning to ensure optimal performance, longevity, and ease of maintenance. Teams should consider water quality, flow rates, storage tank capacity, and recovery rate to match system capacity with operational needs. Proper site preparation, equipment placement, and pre-treatment setup help simplify installation while protecting pumps, membranes, and other critical components. Key steps for effective installation and commissioning include:- Site Preparation: Ensure the location supports electrical, plumbing, and structural requirements, while allowing safe access for chemical programs and routine maintenance.

- Factory Testing: Pre-assembled systems undergo thorough testing to confirm performance specifications before shipment, reducing on-site adjustments.

- Equipment Placement and Easy Installation: Modular designs and space-saving layouts allow teams to install pumps, membranes, and pre-treatment units efficiently, even in facilities with limited floor space.

- Startup Procedures: Initial membrane conditioning, system flushing, and calibration of monitoring controls ensure optimal performance from day one. Proper chemical programs protect membranes and prevent fouling.

- Performance Verification: Validate flow rates, rejection percentages, and recovery rates, documenting baseline data for ongoing maintenance and performance monitoring.

Maintenance, Operational Excellence, and Troubleshooting

Maintaining a commercial reverse osmosis system is essential for ensuring long-term performance and water quality. Operators should establish a preventive maintenance schedule that includes regular inspection and replacement of filters, membranes, pumps, and chemical dosing systems. Teams often catch early issues by monitoring pressure, flow, and water quality, allowing adjustments before performance declines. Training facility personnel is critical. Operators who understand system controls and cleaning protocols can optimize membrane cleaning cycles, reducing chemical use and extending membrane longevity. Data trending and monitoring help identify patterns in water quality and system performance, enabling predictive maintenance rather than reactive repairs. Common issues include pressure drops, flux decline, or changes in rejection rates. These often indicate fouling, scaling, or inadequate pre-treatment. Addressing them promptly maintains system efficiency and minimizes downtime. By combining regular maintenance, proper chemical use, and proactive troubleshooting, teams can optimize water treatment, extend equipment life, and reduce operational costs, ensuring the commercial RO system continues to deliver high-purity water reliably over many years.Cost of Ownership and ROI

When evaluating a commercial reverse osmosis system, it’s important to look beyond the initial price and consider long-term operational savings. While the upfront cost may be higher than alternative water treatment methods, commercial RO systems deliver predictable water quality, protect equipment, and reduce downtime, often offsetting initial investments. Energy consumption is typically 2–4 kWh per 1,000 gallons, though systems with energy recovery and optimized recovery rates can lower these costs significantly. Chemical use and membrane replacement schedules also influence operating costs, with membranes generally lasting 3–7 years depending on water quality and maintenance practices. Routine preventive maintenance keeps both membranes and pumps operating efficiently, reducing unexpected repairs and extending system longevity. Facilities often achieve return on investment within 2–3 years through savings on water procurement, wastewater disposal, energy, and chemical use. Compared with other treatment technologies, commercial RO systems may have a higher upfront cost but deliver superior water quality, reliability, and consistent performance, making them a financially sound choice for industrial applications.Regulatory Compliance and Environmental Impact

Commercial reverse osmosis systems play a key role in helping facilities meet environmental regulations while supporting sustainability goals. Teams should ensure that concentrate disposal complies with EPA and local regulations, and consider zero liquid discharge (ZLD) systems where mandated or desired. Proper water treatment protects water quality and reduces environmental impact by minimizing waste and conserving freshwater resources. Documenting operational data is essential for regulatory compliance. Automated monitoring and reporting simplify record-keeping and provide evidence of water quality, recovery rates, and proper concentrate management. This not only supports inspections but also streamlines internal audits and quality assurance programs. Beyond compliance, commercial RO systems contribute to corporate sustainability initiatives. Reducing water consumption, minimizing waste, and optimizing chemical use align with environmental responsibility while also improving operational efficiency. Facilities pursuing LEED certification can gain points for water efficiency projects, making RO systems a practical choice that delivers measurable benefits for both the environment and the bottom line.Future Trends in Commercial RO Technology

Commercial reverse osmosis systems continue to evolve, offering greater efficiency, sustainability, and adaptability for industrial applications. High-recovery systems are becoming more common, capable of reclaiming over 90% of feed water while maintaining membrane performance through advanced pre-treatment and optimized recovery rates. These systems help facilities reduce waste and move closer to zero liquid discharge goals. Artificial intelligence (AI) is also transforming operations. Predictive algorithms analyze historical and real-time data to optimize chemical dosing, pump operation, and cleaning schedules. Teams can anticipate performance changes before they occur, improving energy efficiency and extending membrane life. Advances in membrane materials further enhance system performance. New chemistries resist fouling, tolerate variable water quality, and deliver higher purity water with less maintenance. Integration with renewable energy sources such as solar or wind supports sustainable operation, particularly in remote or environmentally conscious facilities. By adopting these emerging technologies, industrial operators can optimize water treatment, improve energy efficiency, and support long-term sustainability goals.Steps to Implement a Commercial RO System

Implementing a commercial reverse osmosis system requires careful planning to ensure reliable performance, efficient water treatment, and long-term operational success. Following a clear sequence of steps helps teams optimize installation, maintain system longevity, and protect equipment.- Assess Facility Needs: Evaluate water quality, flow rates, recovery rate, and storage tank capacity to match the commercial RO system to your facility’s operational demands.

- Select the Right System: Choose a system with the appropriate membranes, pre-treatment, and modular design to support both current needs and future expansion.

- Prepare the Site: Ensure electrical, plumbing, and structural requirements are met, and allow safe access for maintenance and chemical programs.

- Coordinate Installation: Proper placement of pumps, membranes, and pre-treatment units ensures easy installation, smooth integration with existing equipment, and reliable performance.

- Establish Maintenance Protocols: Set preventive maintenance schedules, monitor water quality, and optimize membrane cleaning to maintain system longevity and consistent high-purity water.

- Monitor and Optimize: Use data trending and performance tracking to address minor issues early, ensuring the RO system continues to deliver reliable, efficient water treatment.

Frequently Asked Questions (FAQs)

How often should membranes be replaced in a commercial reverse osmosis system?

Membrane life typically ranges from 3–7 years depending on feed water quality, pre-treatment, and maintenance. Regular monitoring of water quality and preventive cleaning helps extend membrane longevity.What energy considerations should I keep in mind for industrial reverse osmosis systems?

Energy consumption varies with flow rates, recovery rate, and system size. Using VFDs and energy recovery devices can optimize energy efficiency and reduce operational costs.How do I determine the right storage tank size?

Storage tank capacity should accommodate peak demand and maintain consistent flow rates, ensuring reliable water supply during high-use periods.What chemicals are necessary for proper system maintenance?

Antiscalants, cleaning solutions, and other chemical programs protect membranes, prevent fouling, and maintain consistent water quality.Can commercial RO systems handle other contaminants beyond dissolved solids?

Yes, properly designed systems can remove bacteria, viruses, and many organic compounds, providing high-purity water suitable for diverse industrial applications.Water Treatment Technologies for Industrial Systems

Water is the lifeblood of any industrial operation. Keeping it clean, safe, and efficient to use means protecting equipment, ensuring product quality, and reducing costs.

Modern water treatment goes far beyond simple filtration. Today’s industrial facilities rely on a mix of advanced processes, from membrane separation to biological treatment, to tackle a wide range of contaminants. Understanding these technologies helps operators choose the right system, optimize performance, and ensure water meets both operational and regulatory standards. In this guide, we’ll break down the key water treatment technologies used in industrial settings, explain how they work, and explore their applications all in clear, practical terms that make sense for facility managers, engineers, and operators alike.What Are Water Treatment Technologies

At their core, water treatment technologies are the tools and processes used to clean water, making it safe, reliable, and fit for purpose. In industrial settings, these technologies don’t just protect public health; they safeguard equipment, support manufacturing processes, and ensure regulatory compliance. Modern systems combine multiple processes to handle a wide range of contaminants efficiently. Key aspects of water treatment technologies include:- Targeting different types of contaminants: Industrial water can carry physical particles like sediments and suspended solids, chemical compounds such as heavy metals and organic contaminants, and biological threats including bacteria and viruses. Each technology focuses on addressing specific challenges.

- Integrated treatment processes: Facilities often use a series of technologies in a carefully designed “treatment train,” where each step complements the next. This combination ensures water meets strict quality standards for industrial use, drinking, or environmental discharge.

- Tailored technology selection: Choosing the right system depends on the type and concentration of contaminants in the water, regulatory requirements, and the unique conditions of the site — from available space to infrastructure constraints.

- Measuring effectiveness: Beyond removing contaminants, industrial water treatment systems are evaluated for energy efficiency, waste generation, operational sustainability, and long-term reliability.

- Regulatory-driven innovation: Standards like those in the EPA’s drinking water treatability database, along with emerging contaminant concerns such as polyfluoroalkyl substances (PFAS), continue to push the development of more advanced, adaptable water treatment solutions.

Physical Water Treatment Technologies

Physical water treatment processes rely on mechanisms such as size exclusion, adsorption, and phase transfer to remove contaminants from water without altering their chemical structure. These treatment processes form the foundation of many water treatment systems, often serving as primary treatment steps or pretreatment for more advanced technologies.1. Filtration and Membrane Processes

Membrane separation processes represent some of the most effective water treatment technologies available today, utilizing semi-permeable barriers to separate contaminants based on molecular size and charge. Reverse osmosis systems operate at high pressures to force water molecules through extremely fine membranes, effectively removing dissolved solids, radionuclides, and synthetic organic compounds with removal efficiencies exceeding 95% for most contaminants. The reverse osmosis process requires significant pressure differentials, typically ranging from 150 to 800 psi depending on the membrane type and water quality parameters. These systems generate a concentrated solution containing 15-30% of the influent water volume as a waste stream, which requires proper disposal or beneficial reuse. The concentrated waste stream contains all rejected contaminants at significantly higher concentrations than the original contaminated water.| Membrane Technology | Pore Size | Primary Applications | Typical Removal Efficiency |

|---|---|---|---|

| Reverse Osmosis | <0.001 µm | Desalination, dissolved organics | >95% for most contaminants |

| Nanofiltration | 0.001-0.01 µm | Hardness removal, organic compounds | 85-95% for target compounds |

| Ultrafiltration | 0.01-0.1 µm | Bacteria, viruses, colloids | >99% for particles >0.01 µm |

| Microfiltration | 0.1-5 µm | Suspended solids, large bacteria | >99% for particles >0.1 µm |

2. Adsorption Technologies

Granular activated carbon (GAC) is one of the most versatile and widely used water treatment technologies, thanks to its high internal surface area that effectively adsorbs organic contaminants. GAC systems can achieve remarkable removal rates for volatile organic compounds, including trichloroethylene (TCE) and perchloroethylene (PCE), often exceeding 99% when properly designed. The performance of activated carbon depends on factors like pH, water temperature, and the presence of competing organics. Contact time is also crucial: longer exposure generally improves contaminant removal, with most systems designed for 10 to 30 minutes to ensure optimal treatment. Specialized adsorptive media based on aluminum, iron, titanium, or zirconium target specific inorganic contaminants such as arsenic, fluoride, and heavy metals, though spent media must be regenerated or disposed of safely. Natural organic matter in the influent water can compete with contaminants for adsorption sites, reducing efficiency. Pretreatment to remove these organics not only improves system performance but also extends the service life of the media. By addressing these variables, adsorption technologies provide reliable, adaptable solutions for industrial water purification.3. Air Stripping Technologies

Air stripping technologies remove volatile contaminants by transferring them from the water phase to the air phase, with effectiveness directly correlated to the contaminant’s volatility as expressed by Henry’s law coefficients. Packed tower aeration systems force contaminated water through structured packing material while air flows counter-currently, maximizing the air-water interface for efficient contaminant transfer. Multi-stage bubble aeration systems utilize shallow basins with fine-bubble diffusers to achieve volatile contaminant removal through enhanced air-water contact. These systems often require multiple stages to achieve target contaminant reduction levels, with each stage providing incremental removal efficiency. The natural flow of air through stripping systems requires careful design to ensure adequate air-to-water ratios for effective treatment. Most air stripping systems operate with air-to-water ratios between 20:1 and 100:1, depending on the specific target contaminant and required removal efficiency. Air pollution control requirements may apply to air stripping systems treating certain volatile organic compounds, particularly in areas with stringent air quality regulations. Community acceptance factors often influence the feasibility of air stripping technologies due to potential odor issues and noise from blower equipment.Chemical Water Treatment Technologies

Chemical water treatment processes utilize chemical reactions to transform, neutralize, or precipitate contaminants, making them easier to remove through subsequent physical separation processes. These treatment technologies often provide highly specific contaminant removal capabilities and can address contaminants that are difficult to remove through physical processes alone.1. Ion Exchange Systems

Ion exchange systems are a key water treatment technology for removing specific ionic contaminants from water. By exchanging undesirable ions for harmless ones using specialized resin materials, these systems provide precise and efficient water purification for both industrial and commercial applications.- Targeting specific contaminants: Anion exchange systems effectively remove contaminants such as arsenic, chromium-6, nitrate, perchlorate, and certain polyfluoroalkyl substances (PFAS), often achieving removal efficiencies above 99% when properly designed and operated. Cation exchange systems focus on positively charged contaminants, including radium, barium, strontium, and hardness-causing calcium and magnesium ions. Water softening, one of the most common residential and commercial applications, relies on cation exchange to improve water quality for consumption and industrial processes.

- System operation and regeneration: Ion exchange resins require periodic regeneration using saturated sodium chloride brine solutions. This process restores the resin’s capacity but generates a concentrated waste stream containing removed contaminants at higher concentrations, which must be managed and disposed of safely.

- Optimizing performance: Adjusting pH can enhance removal efficiency for certain target contaminants, with optimal ranges depending on the resin type and contaminant profile. Many systems include automated chemical feed systems to maintain ideal treatment conditions and consistent water quality.

2. Chemical Oxidation and Reduction

Advanced oxidation processes (AOPs) are among the most powerful water treatment technologies for breaking down stubborn organic contaminants. By generating highly reactive species like hydroxyl radicals, these systems can destroy complex molecular structures that resist conventional treatment, making them ideal for industrial applications requiring high water quality.- Powerful oxidation mechanisms: AOPs combine oxidants such as ozone gas, hydrogen peroxide, and UV light to create conditions capable of treating a wide range of organic compounds. UV oxidation systems using UV light and hydrogen peroxide generate hydroxyl radicals with extremely short half-lives but exceptional reactivity, effectively addressing challenging contaminants like 1,4-dioxane, NDMA, and pharmaceutical residues.

- Dependence on water quality parameters: The success of chemical oxidation is influenced by factors like pH, alkalinity, and the presence of natural organic matter, which can compete with target contaminants. Most processes operate best within a pH range of 6.5–8.5 to optimize hydroxyl radical formation.

- Ozone-based treatment benefits: Ozone systems provide rapid oxidation of organic compounds while simultaneously offering disinfection. Ozone gas is generated on-site and dissolved into water under controlled conditions, including proper water temperature and pH, to maximize treatment efficiency and overall water quality.

3. Coagulation and Precipitation

Coagulation and precipitation are essential water treatment technologies for removing fine particles and dissolved metals from industrial water. By destabilizing suspended particles and forming insoluble compounds, these processes help clarify water, protect downstream equipment, and ensure compliance with water quality parameters.- Coagulation for particle removal: Chemical coagulants like aluminum sulfate (alum) and ferric sulfate neutralize the electrical charges that keep colloidal and fine particles suspended. This allows particles to aggregate into larger flocs that settle more easily, making subsequent sedimentation and filtration more effective.

- Precipitation for dissolved metals: Precipitation removes dissolved metals by forming insoluble compounds that can be separated from the treated water. Maintaining proper pH is critical, as it ensures optimal precipitation and prevents soluble metal complexes from remaining in the water. Automated chemical feed systems with pH monitoring often help maintain consistent treatment performance.

- Optimizing flocculation: Flocculation enhancement provides gentle mixing to encourage particle collisions and floc growth without breaking them apart. Typical retention times in flocculation basins range from 20 to 45 minutes, allowing sufficient time for flocs to form and settle efficiently.

Biological Water Treatment Technologies

Biological water treatment technologies harness the natural metabolic activity of microorganisms to remove contaminants efficiently and sustainably. By converting organic compounds into harmless byproducts like carbon dioxide, water, and biomass, these systems provide cost-effective solutions for industrial water treatment while minimizing chemical waste.

- Microbial contaminant removal: Indigenous bacteria in bioreactors consume organic contaminants as carbon and energy sources. Anoxic biological treatment systems can achieve over 90% removal of nitrate and perchlorate, using specialized bacteria that convert these contaminants into nitrogen gas and chloride ions.

- Supporting microbial activity: Adequate nutrients such as nitrogen and phosphorus, along with carefully dosed electron donors like methanol or ethanol, are essential to maintain active biological communities. Automated nutrient feed systems ensure optimal conditions even when influent water has limited natural nutrients.

- Operational considerations: Biomass management prevents excessive bacterial growth that could reduce treatment efficiency or cause operational issues. Post-treatment measures, including oxygen control, help avoid unwanted biological activity in downstream treatment processes or distribution systems.

- Adaptability and stability: Biological treatment systems naturally adjust to varying contaminant concentrations and types, offering more stable performance compared to chemical treatment processes sensitive to water quality changes in manufacturing processes and industrial applications.

Advanced and Specialized Treatment Technologies

Advanced and specialized water treatment technologies are designed to tackle contaminants that conventional processes cannot fully remove, including emerging contaminants and particularly resistant organic compounds. These systems combine oxidation, disinfection, and corrosion control strategies to ensure safe, reliable, and compliant water for industrial and commercial applications.- UV photolysis and advanced oxidation: UV photolysis uses UV light alone to break down organic contaminants, particularly those with chromophores absorbing 200–280 nm wavelengths. UV/H2O2 systems enhance this process by generating hydroxyl radicals, effectively treating stubborn compounds like 1,4-dioxane, NDMA, and MTBE. Emerging UV/chlorine systems create multiple reactive species while leveraging existing chlorine infrastructure for superior performance. Energy-efficient UV lamps and optimized reactor designs help minimize operational costs, and regular lamp maintenance ensures consistent treatment effectiveness.

- Disinfection technologies: Chlorine-based disinfection, including chlorine dioxide, provides robust pathogen control while producing fewer disinfection byproducts. UV disinfection inactivates bacteria, viruses, and chlorine-resistant protozoa without chemical addition, while ozonation delivers both oxidation and disinfection benefits. Maintaining residual disinfection in the distribution system often involves chloramines to prevent recontamination while balancing regulatory and water quality requirements.

- Corrosion control systems: Caustic feed systems using sodium hydroxide adjust pH to prevent metal leaching, and phosphate feed systems form protective films on pipe surfaces to reduce lead and copper levels for Lead and Copper Rule compliance. Sophisticated chemical dosing systems with automated monitoring and redundant feed equipment ensure consistent protection under variable water demand. Safety considerations, including proper storage, handling, and emergency response, are critical when working with concentrated chemicals.

Technology Selection and Implementation

Selecting appropriate water treatment technologies requires comprehensive evaluation of multiple factors to ensure effective, economical, and sustainable treatment solutions. The decision-making process must consider contaminant characteristics, site conditions, regulatory requirements, and long-term operational considerations.Design Considerations

Selecting the right water treatment technologies starts with understanding the specific characteristics of the water and contaminants to be treated. Proper design ensures that industrial and commercial treatment systems operate efficiently, meet regulatory requirements, and adapt to changing water conditions.- Contaminant type and concentration: The type, concentration, and mass loading of contaminants influence system sizing and technology selection. Higher contaminant levels often require more robust treatment approaches or multiple stages to achieve the desired removal efficiency.

- Water quality parameters: Factors such as pH, alkalinity, hardness, and natural organic matter content directly impact treatment effectiveness. Pretreatment adjustments may be necessary to optimize downstream water treatment processes and ensure consistent performance.

- Regulatory requirements: Discharge limitations and regulatory standards set minimum performance criteria. Systems must maintain compliance even during peak loading, maintenance periods, or other operational fluctuations.

- Site-specific conditions: Available space, existing infrastructure, power supply, and environmental constraints often dictate feasible technology options. Compact systems may suit urban facilities, while larger, less intensive setups can work in rural locations.

- Influent water variability: Seasonal changes, storm events, and other factors affect influent water quality. Flexible treatment systems with adjustable operating parameters help maintain reliable performance under variable conditions.

Cost and Duration Factors

Capital costs for water treatment systems vary significantly based on technology complexity, system size, and site preparation requirements. Membrane processes and advanced oxidation systems typically require higher initial investments compared to conventional technologies like granular activated carbon or air stripping. Operation and maintenance costs include ongoing expenses for chemicals, energy consumption, waste disposal, and equipment replacement. These recurring costs often represent a significant portion of total treatment costs over the system’s operational life and must be carefully evaluated during technology selection.| Treatment Technology | Annual O&M Cost | Primary Cost Drivers |

|---|---|---|

| Granular Activated Carbon | 5-15% of capital | Media replacement, pressure loss |

| Reverse Osmosis | 8-20% of capital | Membrane replacement, energy |

| Ion Exchange | 10-25% of capital | Resin replacement, brine disposal |

| Air Stripping | 3-10% of capital | Energy, air emission control |

Alternative Approaches

Nontreatment options, such as interconnection with uncontaminated water supplies, can offer cost-effective solutions when only part of a system is affected by contamination. These approaches typically require less capital investment and ongoing operational attention compared to active water treatment technologies. Installing new wells to access uncontaminated aquifers provides a permanent solution, eliminating ongoing treatment costs while ensuring long-term water supply security. Feasibility and optimal well placement are determined through detailed hydrogeological investigations. Additionally, beneficial reuse of treated water maximizes the value of treatment systems and supports sustainable water management, often requiring higher treatment standards but offering greater operational flexibility. For sites with complex contamination profiles, combination treatment trains that integrate multiple water treatment technologies in series provide the most comprehensive contaminant removal. Sequential processes can be optimized for specific contaminants, improving overall efficiency while minimizing costs, making these integrated approaches particularly valuable for industrial and commercial applications.Partner with ProChem for Reliable Industrial Water Treatment

When it comes to industrial water management, choosing the right water treatment technologies is just the first step. Effective implementation, ongoing operation, and regulatory compliance are equally critical, and that’s where ProChem excels. With decades of experience supporting industrial facilities, ProChem designs, installs, and maintains treatment systems that deliver clean, safe, and efficient water while optimizing costs and protecting equipment.- Customized solutions: ProChem evaluates your site’s unique influent water quality, contaminant profile, and operational requirements to recommend the most effective combination of physical, chemical, biological, and advanced treatment technologies.

- Full-service support: From system design and installation to monitoring, maintenance, and troubleshooting, ProChem ensures your water treatment systems operate at peak performance with minimal downtime.

- Regulatory confidence: ProChem stays ahead of evolving water quality standards, including emerging contaminants and EPA guidelines, helping your facility remain compliant while safeguarding both people and processes.

Frequently Asked Questions (FAQs)

What is the most effective water treatment technology for removing PFAS compounds?

For polyfluoroalkyl substances (PFAS), granular activated carbon and ion exchange systems currently provide the most effective removal, with properly designed systems achieving over 95% removal efficiency. Advanced oxidation processes using UV/hydrogen peroxide are also emerging as effective treatment options for certain PFAS compounds, though treatment effectiveness varies significantly among different PFAS chemicals.How do I determine which water treatment technology is most cost-effective for my specific contamination problem?

Cost-effectiveness depends on contaminant type and concentration, required treatment standards, site conditions, and long-term operational considerations. A comprehensive evaluation should include pilot testing of promising technologies, detailed cost analysis including capital and operational expenses, and consideration of waste disposal requirements. Professional consultation with water treatment engineers familiar with your specific contaminants typically provides the most reliable technology selection guidance.What are the main waste streams generated by different water treatment technologies and how are they managed?

Different technologies generate distinct waste streams: reverse osmosis and nanofiltration produce concentrated brine containing rejected contaminants, granular activated carbon generates spent media requiring disposal or regeneration, ion exchange systems produce regeneration brines, and air stripping may require air emission control. Waste management strategies include hazardous waste disposal, beneficial reuse where possible, and specialized treatment of waste streams to reduce disposal costs.Can multiple water treatment technologies be combined, and what are the benefits of treatment trains?

Treatment trains combining multiple technologies provide superior contaminant removal compared to single-technology approaches, particularly for sites with various contaminants requiring different removal mechanisms. For example, combining air stripping for volatile organic compounds with granular activated carbon for non-volatile organics and ion exchange for inorganic contaminants can address complex contamination profiles more effectively and economically than using any single technology alone.How long does it typically take to implement a water treatment system and achieve regulatory compliance?

Implementation timelines vary significantly based on system complexity, permitting requirements, and site conditions. Simple systems like granular activated carbon installations may be operational within 3–6 months, while complex membrane systems or custom-designed treatment trains may require 12–24 months from design initiation to full operation. Regulatory approval processes, equipment procurement, construction, and system startup and optimization each contribute to overall implementation timeframes.Selecting an Industrial Reverse Osmosis System

Water is one of the most critical resources in industrial operations, and managing its quality can make or break production efficiency. An industrial reverse osmosis system provides a reliable solution, turning raw water into purified water that meets the demanding needs of heavy industry. These reverse osmosis systems are engineered for continuous, large-scale operation, offering industrial water solutions that protect equipment, reduce downtime, and maintain consistent product quality across power plants, automotive facilities, and wood processing operations.

In this article, we’ll guide you through the key aspects of industrial reverse osmosis systems, from understanding how reverse osmosis systems work to selecting the right system size and maintaining peak performance. You’ll discover practical insights on industrial water solutions that help facilities remove dissolved solids, optimize water use, and ensure reliable operations, all while reducing costs and extending the life of critical equipment.What is an Industrial Reverse Osmosis System?

An industrial reverse osmosis system is a high-capacity water treatment solution designed to deliver purified water for demanding industrial applications. Unlike a commercial reverse osmosis system, which is suited for smaller-scale or light commercial use, industrial RO systems are built for continuous operation, handling large volumes of feed water while removing dissolved solids and other contaminants through advanced semi permeable membrane technology. These systems are essential for industries like power generation, automotive manufacturing, and wood processing, where consistent water quality directly impacts equipment performance and product standards. Key features and benefits of industrial RO systems include:- Continuous large-scale operation: Industrial RO systems are engineered with robust pumps and multiple membrane trains to maintain steady performance under heavy-duty conditions, unlike smaller commercial reverse osmosis systems.

- Effective TDS reduction: These systems can lower total dissolved solids (TDS) from over 1,000 ppm to less than 10 ppm, producing high-purity water that protects critical equipment and industrial processes.

- Advanced semi permeable membranes: The heart of the system, membranes selectively allow water molecules to pass while blocking contaminants, ensuring reliable water treatment at industrial scale.

- Industrial water solutions for diverse applications: By delivering clean, low-TDS water, these systems support processes in power plants, automotive production, and wood treatment operations, improving efficiency, product quality, and regulatory compliance.

- Operational reliability and longevity: Industrial RO systems are designed to handle fluctuating feed water quality and continuous production demands, minimizing downtime and maintenance while maximizing system life.

How Industrial RO Systems Work

Industrial reverse osmosis systems purify water by using pressure to force feed water through semi permeable membranes, separating dissolved solids and other impurities from clean water. This osmosis system is designed for continuous, large-scale industrial operation, ensuring high-purity water while protecting critical equipment and supporting consistent process performance.- Pressure-driven filtration: Applying pressure pushes water molecules through the membrane surface while dissolved solids are left behind, producing purified water for industrial applications.

- Cross-flow design: Part of the feed water flows along the membrane surface, carrying away concentrated impurities to prevent fouling and maintain system efficiency.

- Multi-stage configuration: Several pressure vessels arranged in series allow the system to achieve high water recovery rates and consistent quality across large volumes.

- Automated controls and monitoring: Sensors track feed water, flow rates, and system pressure, while PLCs adjust pumps and valves, trigger cleaning cycles, and alert operators to potential issues.

- Optimized performance: Regular monitoring and control help maintain membrane life, reduce energy consumption, and ensure the osmosis system delivers reliable water for industrial operations.

Key Industrial Applications

Industrial reverse osmosis systems are essential across multiple industrial applications, providing high purity water that supports critical processes while protecting equipment and maintaining consistent water quality. Operators in heavy industry rely on these systems to reduce dissolved solids, improve efficiency, and ensure compliance with internal and regulatory standards.- Power Generation and Boiler Feed Water:

- RO-treated water removes scale-forming minerals like calcium, magnesium, and silica, protecting high-pressure boilers and turbines from corrosion and fouling.

- Large-scale facilities often operate 500–5,000 GPM systems to meet continuous steam generation demands, with recovery rates of 75–85% helping minimize freshwater use.

- Operators should regularly monitor feed water TDS and check for early signs of scaling; adjusting pretreatment chemicals can prevent costly downtime and efficiency losses.

- Automotive Manufacturing Processes:

- Automotive plants rely on industrial RO systems for paint booth operations, parts washing, and engine cooling, where even minor variations in water quality can impact product quality.

- Purified water prevents paint defects, water spotting on finished components, and corrosion in cooling systems, supporting high manufacturing standards.

- Operators often catch early issues by monitoring flow rates and conductivity, ensuring consistent water quality across production shifts.

- Wood Processing and Treatment Operations:

- Pulp, paper, and engineered wood facilities use RO systems to maintain consistent chemical reactions during bleaching, adhesive curing, and kiln drying, improving product uniformity and reducing chemical consumption.

- High-purity water ensures even penetration of preservatives and minimizes mineral deposits that can compromise wood surface quality.

- Advisory tip: Regularly verify system pressure and conduct water quality tests to prevent fouling and optimize membrane life.

- Additional Industrial Water Solutions:

- Across these sectors, industrial RO systems allow facilities to recycle treated water, reduce environmental discharge, and improve operational efficiency.

- Teams should review membrane performance trends, adjust cleaning protocols, and plan for peak demand to maintain continuous operation and minimize maintenance interruptions.

System Sizing and Capacity Planning

Choosing the right industrial reverse osmosis system begins with understanding your facility’s water needs. Proper sizing ensures consistent water quality, protects equipment, and avoids unnecessary energy or chemical costs. Operators should consider not just current demands but also peak flow, recovery rate, and potential future expansion when planning system capacity.- Assessing Process Demands and Feed Water:

- Evaluate the volume and quality of feed water for each industrial application, including variations in total dissolved solids and potential contaminants.

- Review peak flow requirements during production surges, ensuring the RO system can handle maximum demand without sacrificing water quality or system performance.

- Advisory tip: Monitor feed water trends regularly, as seasonal or operational changes can affect sizing decisions and membrane performance.

- Typical Capacities and Recovery Rates:

- Industrial RO systems range from 100–10,000+ GPM, depending on application scale—from automotive manufacturing lines to power generation boilers.

- Incorporate 20–30% excess capacity to accommodate maintenance, future growth, or temporary surges in water demand.

- Recovery rates of 75–85% are common, balancing efficient freshwater use with safe concentrate handling and disposal.

- Practical Tips for Matching Production Requirements:

- For facilities with multiple production lines, consider parallel membrane trains to provide flexibility and uninterrupted water supply.

- Factor in system downtime for cleaning or membrane replacement, and plan capacities so production continues smoothly during maintenance cycles.

- Operators often improve reliability by integrating automated controls that adjust flow rates based on real-time demand, maintaining both efficiency and consistent water quality.

Components and Design Considerations

A high-performing industrial reverse osmosis system relies on well-engineered components working together seamlessly. Understanding each part helps operators maintain reliability, extend membrane life, and optimize water quality. These systems combine advanced water treatment equipment, membrane technology, and automation to handle demanding industrial applications.- Pretreatment Systems:

- Pretreatment protects membranes by removing suspended solids, hardness, chlorine, and other contaminants before water reaches the RO system.

- Common filtration techniques include multimedia filters, water softeners, and antiscalant dosing to prevent scaling and fouling.

- Advisory tip: Regular monitoring of pretreatment performance prevents early membrane degradation and keeps recovery rates high.

- Membranes, Pumps, and Cleaning Systems:

- Membrane arrays form the core of industrial RO systems, with parallel configurations in membrane systems providing redundancy for continuous operation.

- High-pressure pumps deliver consistent feed water pressure, critical for optimal reverse osmosis performance.

- Clean-in-place (CIP) chemical programs maintain membrane efficiency by removing scale, biofilm, and other fouling, extending service life without disassembling the system.

- Materials and Vessel Design:

- Pressure vessels are typically stainless steel or fiberglass to withstand industrial operating pressures and corrosive feed water.

- Multi-stage membrane systems are arranged to maximize recovery while protecting membranes from concentrated dissolved solids.

- Selecting the right vessel material ensures durability and reduces long-term maintenance costs.

- Automation and Monitoring:

- Modern RO systems integrate PLC-based controls for real-time monitoring of flow rates, pressure, and water quality parameters.

- Automated alarms and performance tracking help operators catch issues early, reducing downtime and protecting sensitive equipment.

- For a deeper look at industrial RO system features, see ProChem’s system solutions and features.

Performance Optimization and Monitoring

Maintaining optimal performance in an industrial reverse osmosis system requires continuous attention to water quality and proactive management of membranes and chemicals. Operators who actively monitor system conditions can prevent downtime, extend membrane life, and ensure consistent removal of impurities.- Monitoring Critical Parameters:

- Track feed pressure, permeate flow, and conductivity to detect shifts in water quality that may indicate membrane fouling or scaling.

- Small fluctuations often signal issues early, allowing teams to take corrective action before production is impacted.

- Advisory note: Regular checks help maintain target recovery rates while protecting downstream equipment.

- Data-Driven Cleaning and Energy Recovery:

- Schedule chemical cleaning cycles based on system performance data rather than fixed intervals to maximize membrane life and reduce chemical use.

- Energy recovery devices capture pressure from the concentrate stream, lowering operating costs, particularly in high-pressure or high-TDS applications.

- Operators often catch efficiency losses by comparing historical performance trends and adjusting chemical dosing or flow rates accordingly.

- Regular Membrane Analysis:

- Periodic membrane autopsy and inspection reveal early signs of fouling, scaling, or biological growth, preventing unexpected downtime.

- Addressing minor issues promptly ensures consistent water quality and reduces long-term repair costs.

- For detailed guidance, see our system performance and maintenance blog.