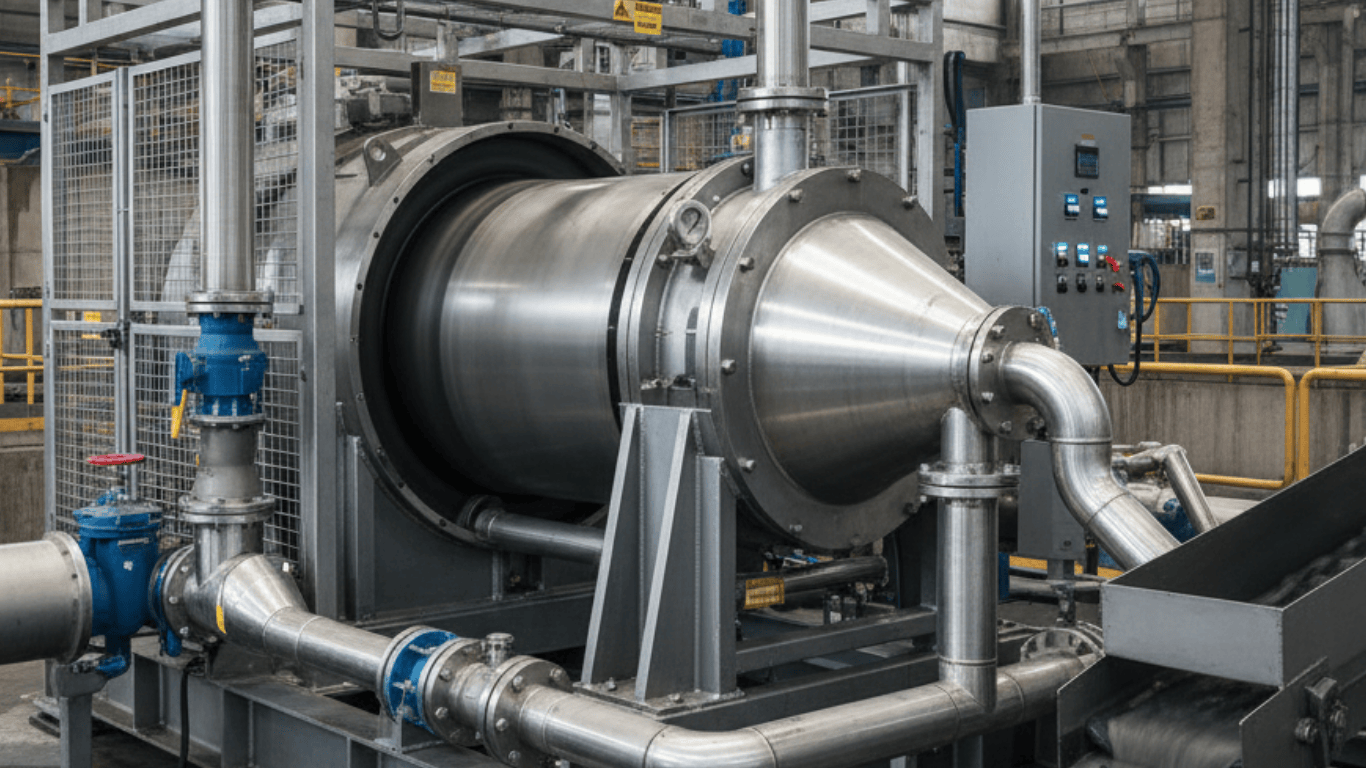

When you run a wastewater plant, the sludge can be just as challenging as the water itself. It’s heavy, wet, and costly to move or dispose of, and if you’re not careful, it can become a real bottleneck in your operations. That’s why wastewater centrifuges are such a game-changer. They use rapid spinning to separate solids from liquids, making sludge easier to handle and leaving cleaner water behind.

Over the next few sections, we’ll share what we’ve learned about these machines: how they work, the types you’ll encounter, and what to watch for in day-to-day operation.What is a Wastewater Centrifuge

A wastewater centrifuge is a high-speed machine that separates solids from liquids using centrifugal force. Think of it as a fast-forward version of gravity separation. It does in minutes what traditional settling takes hours or days to accomplish. Here’s a closer look:How It Works

- The machine spins rapidly, pushing heavier solids outward to the bowl wall.

- Lighter liquid stays near the center, producing clarified water suitable for reuse or safe discharge.

- The separated solids form a compact “cake” that’s much easier to handle and transport.

Where It’s Used

- Municipal wastewater plants: Processes primary sludge, waste activated sludge, and digested sludge from anaerobic digesters.

- Industrial facilities: Treats process water containing suspended solids, oil, or valuable materials requiring recovery before disposal.

Why Operators Prefer It

- Continuous operation: No waiting for batch cycles like filter presses.

- Minimal supervision needed, though monitoring cake dryness and vibration helps catch early issues.

- Higher dry solids content and lower disposal costs compared to older methods like belt filters or gravity thickeners.

How Wastewater Centrifuges Work

Understanding how a wastewater centrifuge operates makes it easier to troubleshoot, optimize, and get the best results from your sludge dewatering process. Here’s a breakdown of the key principles and components.The Principle

- Centrifugal force: Rapid spinning generates forces 2,000–3,100 times stronger than gravity.

- Solids separate from liquids based on density: heavier solids move outward to the bowl wall, while lighter liquids stay near the center.

- The result: dewatered sludge cake and clarified liquid (centrate).

Key Components

- Cylindrical bowl: Spins at high speed to create centrifugal force.

- Internal auger or scroll conveyor: Rotates slightly slower than the bowl, continuously moving solids toward the discharge point without disrupting separation.

- Centrate outlet: Collects the clarified liquid for reuse or safe discharge.

Operating Parameters

- Bowl speed: Determines the force applied; higher speeds generally improve separation but increase energy use.

- Differential speed: The difference between bowl and conveyor speed controls cake dryness.

- Feed rate: Affects residence time; too fast can reduce separation efficiency.

- Retention time: Usually 2–8 minutes depending on sludge type, giving solids enough time to migrate to the bowl wall.

Practical Advice

Operators often notice early issues through:- Changes in cake consistency

- Unexpected vibration

- Variations in centrate clarity

Types of Wastewater Centrifuges

Not all centrifuges are created equal. Depending on the sludge type, volume, and separation needs, different designs offer distinct advantages. Here’s a breakdown of the main types you’ll encounter in the field.1. Decanter Centrifuges

- Design: Horizontal bowl, ideal for high-volume sludge dewatering.

- Applications: Municipal wastewater, industrial effluents, and digested sludge.

- Advantages: Handles large flows continuously, produces high dry solids content, and reduces polymer use compared with other methods.

2. Disc-Stack Centrifuges

- Design: Vertical stack of conical plates, compact footprint.

- Applications: Fine particle separation in mining, food processing, and industrial water treatment.

- Advantages: Excellent for removing very small solids, self-cleaning bowls, and space-efficient installation.

3. Three-Phase Separators

- Design: Specialized for separating oil, water, and solids in a single stage.

- Applications: Petrochemical, metal fabrication, and automotive facilities with oily wastewater.

- Advantages: Simultaneous separation of three phases, recovered oil can be reused or sold, reduces hazardous waste disposal costs.

Choosing the Right Type

When deciding which centrifuge to use, consider:- Sludge characteristics: Particle size, solids concentration, and chemical composition.

- Processing volume: High-flow municipal plants usually need decanter centrifuges, while smaller or specialized flows might benefit from disc-stack or three-phase units.

- Separation goals: Are you prioritizing dry solids, fine particle removal, or oil recovery?

Decanter Centrifuges for Sludge Dewatering

Decanter centrifuges are the workhorses of municipal and industrial wastewater treatment. If your facility handles large volumes of sludge, this is likely the type you’ll encounter most often.Design and Operation

- Horizontal cylindrical bowl: Spins at 1,800–3,500 RPM to generate centrifugal forces that separate solids from liquids.

- Internal scroll conveyor: Rotates slightly slower than the bowl to move solids toward the discharge outlet without disturbing separation.

- Capacity: Can process 50–500 gallons per minute, depending on the unit size.

Applications

- Municipal plants: Primary sludge, waste activated sludge, and digested sludge from anaerobic digesters.

- Industrial facilities: Effluents containing suspended solids, food processing waste, or other high-volume sludge streams.

Enhancing Performance

- Polymer addition: Cationic polymers bind fine particles into larger aggregates for more efficient separation. Typical dosing ranges from 2–8 pounds per dry ton, optimized through jar testing.

- Monitoring: Watch cake consistency and centrate clarity to ensure proper operation; small adjustments can significantly improve dewatering efficiency.

Why Decanters Are Valuable

- Continuous, high-capacity operation with minimal downtime.

- High dry solids content, reducing disposal volume and costs.

- Reliable for a wide range of sludge types and easy integration into municipal or industrial plants.

Disc-Stack Centrifuges for Fine Particle Separation

Disc-stack centrifuges are designed for precision. When your wastewater contains very fine solids that gravity settling or decanter centrifuges can’t handle efficiently, this type is a strong option.Design and Operation

- Vertical bowl with conical discs: Spinning at 6,000–10,000 RPM, the stacked discs increase the effective settling area without taking up much floor space.

- Self-cleaning feature: Solids automatically discharge through peripheral nozzles during operation, eliminating lengthy manual cleaning cycles.

- Capacity: Ideal for lower volume flows but capable of handling very fine particles (0.1–10 microns).

Applications

- Mining wastewater: Copper, coal, and gold operations removing fine mineral particles.

- Food and beverage: Clarifying process water or recovering valuable solids.

- Industrial effluents: Removing fine solids that interfere with water reuse or discharge compliance.

Operational Insights

- High-speed rotation separates extremely small particles that would remain suspended in conventional settling systems.

- Operators often monitor vibration and centrate clarity; small changes can indicate wear or feed inconsistencies.

- Works well in space-constrained facilities due to compact design and easy retrofit potential.

Why Disc-Stack Works

- Excellent fine particle removal.

- Continuous operation with minimal downtime.

- Efficient water recovery and minimal maintenance.

Three-Phase Separators for Oily Wastewater

When wastewater contains oil along with solids and water, a three-phase separator is often the best solution. These machines handle complex mixtures that other centrifuges struggle with.Design and Operation

- Single-stage separation: Simultaneously separates oil, water, and solids.

- High-speed spinning: Centrifugal force drives denser solids outward, water stays in the middle, and oil rises to the top or is collected separately.

- Self-cleaning: Solids discharge automatically, keeping operation continuous.

Applications

- Petrochemical plants: Treat process wastewater with emulsified hydrocarbons and suspended catalyst particles.

- Metal fabrication: Recover coolant, remove tramp oils, and separate metallic particles.

- Automotive manufacturing: Treat oily wash water and cutting fluid waste.

Operational Insights

- Operators monitor oil layer thickness and cake dryness to ensure efficient separation.

- These units often integrate with recycling systems, allowing recovered oil or water to be reused in the process.

- Reduces hazardous waste volumes, cutting disposal costs while maintaining regulatory compliance.

Why Three-Phase Separators Are Valuable

- Recover valuable oil or process fluids.

- Achieve high separation efficiency, often exceeding 95% for oil and solids.

- Reduce transportation and disposal costs significantly by concentrating waste streams.

Benefits and Advantages of Wastewater Centrifuges

Wastewater centrifuges transform how a facility handles sludge and water separation. Here’s why operators and engineers favor them over older technologies.Operational Efficiency

- Continuous operation: Unlike batch systems such as filter presses, centrifuges work 24/7 with minimal interruption.

- Automated control: Modern units adjust bowl speed, differential speed, and polymer dosing automatically, reducing the need for constant operator supervision.

- Scalability: From 50 GPM small industrial units to 2,000 GPM municipal systems, centrifuges can be sized for your specific needs.

- Quick startup and shutdown: Takes 15–30 minutes versus hours for other systems, allowing rapid response to changes in flow or emergency conditions.

Cost Savings

- Reduced disposal and transportation costs: Higher dry solids content means fewer truckloads and lower tipping fees.

- Labor efficiency: Single operators can manage multiple units, saving on staffing.

- Lower polymer usage: Automated dosing typically reduces chemical consumption by 10–30%.

- Energy savings: More efficient than thermal drying systems, often reducing energy use by 30–50%.

Reliability and Maintenance

- Long service life: Stainless steel construction lasts 20–25 years, resisting chemical attack.

- Minimal wear parts: Bearings and major components usually last 10+ years before major maintenance.

- Predictive maintenance: Vibration and performance monitoring catch issues early, preventing unexpected downtime.

- Field service support: Manufacturers provide remote monitoring, 24-hour emergency response, and technical guidance.

Environmental and Regulatory Advantages

- Higher cake solids: Reduces landfill disposal volumes and associated tipping fees.

- Clean centrate: Meets or exceeds regulatory standards for water discharge or reuse.

- Oil and resource recovery: In three-phase systems, reclaimed oil or process fluids reduce hazardous waste and generate economic value.

Selection and Sizing Criteria

Choosing the right wastewater centrifuge isn’t just about picking a model off a catalog. The right selection ensures efficiency, reliability, and cost savings. Here’s what operators and engineers consider before making a decision.1. Sludge Characteristics

- Particle size: Fine particles may need disc-stack centrifuges, while coarser solids work well with decanter systems.

- Solids concentration: Higher feed solids improve throughput but may require more polymer for effective separation.

- Chemical composition: Certain industrial sludges require specialized materials or polymer conditioning.

2. Processing Volume

- Average and peak flow rates: Municipal plants often design for 150–200% of average daily flow to handle peaks.

- Number of units: Large facilities may install multiple smaller centrifuges for redundancy and flexibility.

3. Equipment Sizing

- Bowl dimensions: Longer bowls provide more retention time for difficult-to-dewater sludges.

- Motor size and power requirements: Typically range from 50–500 HP depending on flow and feed solids.

- Integration with plant infrastructure: Check space, electrical service, and control system compatibility.

4. Polymer and Chemical Conditioning

- Proper dosing and mixing are critical for forming flocs that separate easily under centrifugal force.

- Typical dosing ranges from 2–10 kg of active polymer per dry ton, adjusted based on pilot testing or jar tests.

5. Total Cost of Ownership

- Consider capital cost versus operating expenses over the expected 20–25 year equipment life.

- Factor in energy consumption, polymer usage, labor, maintenance, and disposal savings to compare options.

Practical Advice

Operators often find that pilot testing with representative sludge samples is invaluable. Running a small-scale unit for 2–4 weeks helps fine-tune polymer type, dosing, and operational parameters, ensuring the full-scale system performs as expected. Selecting the right centrifuge isn’t just about the machine—it’s about matching technology to sludge, volume, and long-term operational goals. Taking the time to analyze these factors pays off in efficiency, reliability, and reduced costs.Installation and Maintenance of Wastewater Centrifuges

Installing a wastewater centrifuge properly and keeping it well-maintained ensures long-term performance, reduces downtime, and maximizes cost savings. Here’s a practical guide from an operator’s perspective.Installation Considerations

- Foundation: Must support dynamic loads; concrete bases typically 3–5 feet deep with reinforced steel for large units.

- Vibration isolation: Pads and spring mounts reduce vibration transmission to surrounding structures.

- Utility connections: Electrical service (480V–4,160V), control systems, and polymer dosing pumps must be properly installed.

- Space planning: Allow 20–30 feet of clearance around units for maintenance access and overhead crane operation.

Commissioning

- Test with actual sludge to verify guaranteed separation efficiency and capacity.

- Typical commissioning period: 30–60 days, ensuring consistent performance under varying conditions.

- Operator training: 40–80 hours of classroom and hands-on instruction on normal operation, routine maintenance, and troubleshooting.

Routine Maintenance

- Daily checks: Vibration, bearing temperature, and visual inspection for leaks or unusual conditions.

- Weekly maintenance: Lubricate bearings and drive components (2–4 hours per unit).

- Annual overhauls: Inspect wear parts, replace bearings, and recalibrate control systems (2–5 days downtime).

- Spare parts inventory: Maintain critical components like bearings, seals, and drive belts for immediate replacement.

Cleaning Cycle

- Automated wash systems remove accumulated deposits without manual intervention.

- Operators should monitor cleaning frequency based on sludge type and polymer use.