Across the water industry, teams are always looking for ways to make treatment processes cleaner, smaller, and more efficient. One technology that continues to raise the bar is the membrane bioreactor for wastewater treatment. By combining proven biological treatment with advanced membrane filtration, MBR systems deliver high-quality effluent that’s safe for reuse and meets strict discharge limits.

In the sections ahead, we’ll take a closer look at how MBRs work, their components, and the best ways to keep them running efficiently for years to come.How a Membrane Bioreactor Works

At its core, a membrane bioreactor (MBR) combines two powerful treatment methods, which are biological treatment and membrane filtration, into one compact system. This integration allows facilities to clean wastewater more efficiently while producing consistent, high-quality effluent.1. The Biological Treatment Stage

Inside the bioreactor, microorganisms consume and break down organic matter, much like what happens in a conventional activated sludge process. This biological activity is essential for reducing pollutants and preparing the water for the next stage.2. The Membrane Filtration Stage

Instead of relying on a secondary clarifier or settling tank, the membrane does the separation work. It physically filters the treated water, holding back:- Suspended solids

- Bacteria and pathogens

- Fine organic particles

3. Two Main MBR Configurations

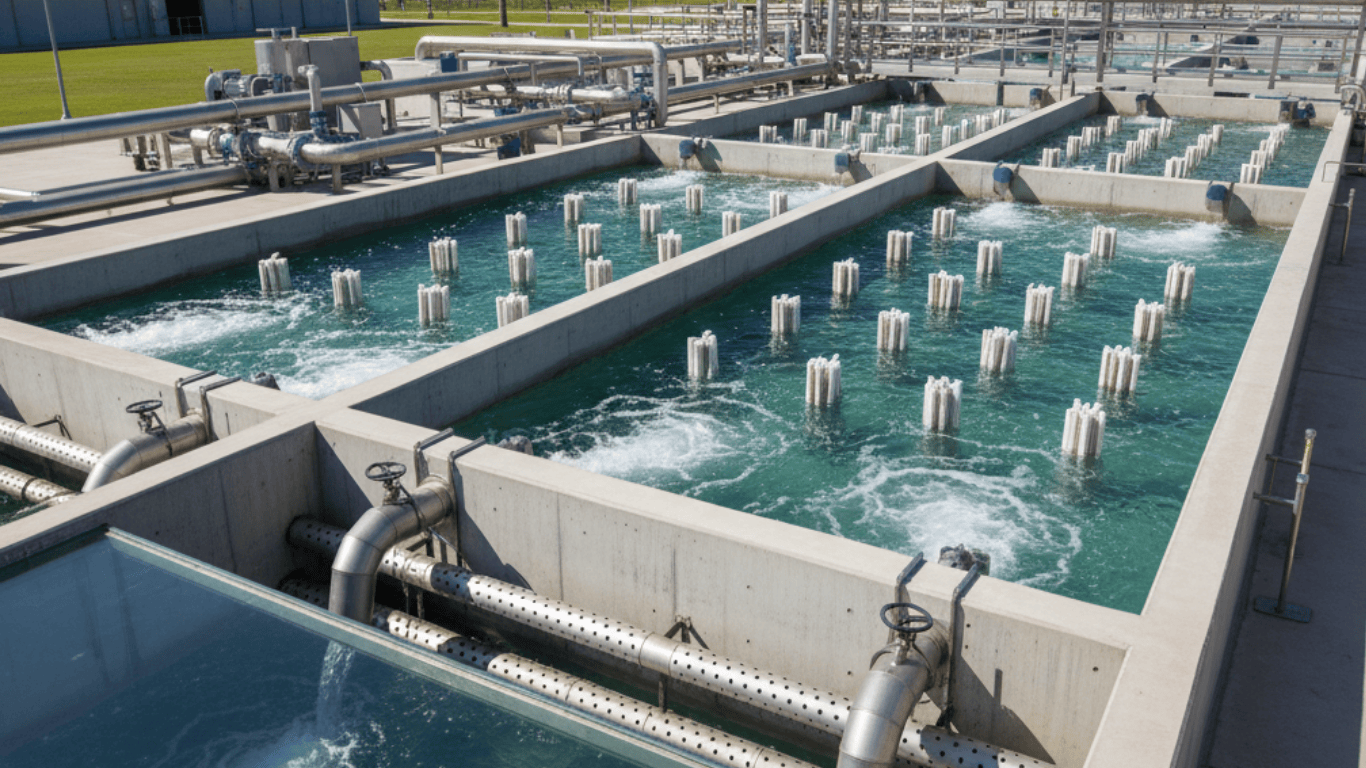

MBR systems generally fall under two setups, each suited to different operational needs:- Submerged membranes – Installed directly inside the bioreactor; commonly used for municipal wastewater treatment due to simpler operation and lower energy needs.

- Side-stream membranes – Located outside the bioreactor; ideal for industrial wastewater applications where higher operating pressures and stronger cleaning cycles are required.

Core Components of an MBR System

Every membrane bioreactor relies on a few key components working in balance. When each part operates as intended, the system produces consistent, high-quality effluent with minimal maintenance issues. Let’s take a closer look at the major components that make up an effective MBR setup.1. The Bioreactor

This is where the main biological process happens. The bioreactor serves as a controlled environment where microorganisms feed on organic matter and nutrients in the wastewater. Teams often monitor parameters like mixed liquor suspended solids (MLSS) and biomass concentration to maintain a stable process. A well-managed bioreactor ensures the downstream membranes don’t get overloaded.2. The Membrane Modules

Membranes act as the final barrier that separates treated water from solids. Different membrane modules are available depending on the application and space:- Flat sheet membranes – Easy to clean and commonly used in municipal wastewater treatment.

- Tubular membranes – Ideal for high-strength industrial wastewater treatment.

- Hollow fiber membranes – Offer a high membrane surface area in a compact space.

3. Membrane Materials

The type of membrane material directly affects fouling resistance and lifespan.- Polymeric membranes, such as PVDF, are flexible and cost-effective.

- Ceramic membranes offer superior durability and are often used where cleaning frequency or harsh wastewater conditions are expected.

4. The Aeration Tank

Aeration keeps the biomass active and supplies oxygen for microbial growth. It also helps limit fouling by creating turbulence near the membrane surface, preventing buildup. The right balance of air and mixing ensures a healthy biological environment and stable operation. Understanding these components gives operators a clearer picture of how to fine-tune performance and design systems that fit their treatment goals.Why Teams Choose MBR Systems

More facilities are switching to membrane bioreactor systems because they solve problems that conventional wastewater treatment can’t easily handle. From tighter discharge standards to limited space, MBRs offer a modern answer that balances performance and reliability.1. Superior Effluent Quality

The membrane acts as a physical barrier that blocks even the smallest particles, producing effluent clear enough for reuse. MBR-treated water often meets or exceeds Class A reuse standards, making it ideal for irrigation, cooling towers, and other non-potable applications.2. Smaller Footprint

Because MBRs eliminate the need for large settling tanks, they can treat the same volume of water using far less space. This compact design makes them a strong fit for urban treatment plants, industrial facilities, or any site with limited real estate.3. Stable and Reliable Operation

MBRs maintain consistent treatment quality even when influent loads fluctuate. Their combination of biological treatment and membrane separation helps absorb shock loads, keeping effluent quality steady without constant operator intervention.4. Easy Integration for Water Reuse

With growing demand for wastewater recycling, MBRs are often the preferred choice for plants aiming to reuse water safely. The consistent effluent quality simplifies the next treatment steps, such as disinfection or reverse osmosis, reducing the overall complexity of reuse systems.5. Lower Sludge Production

MBRs generally produce less waste activated sludge compared to conventional processes, cutting down on disposal costs and handling requirements. That’s a win for both operations and sustainability goals. For many operators, these combined advantages make MBRs less of an experimental technology and more of a dependable standard.The Ongoing Challenge: Membrane Fouling

Membrane fouling is the single most persistent operational challenge in membrane bioreactor systems. In plain terms, fouling happens when particles, colloids, organic matter, or biological growth accumulate on the membrane surface or inside the membrane pores, reducing flow and forcing higher energy use. Teams usually spot a problem when transmembrane pressure trends upward or permeation flux drops at a given operating point. Common fouling modes include:- Cake layer formation, where solids collect on the membrane surface and form a compact layer.

- Pore blocking, when colloidal or fine particles plug membrane pores.

- Biofouling, driven by biofilms, extracellular polymeric substances (EPS), and soluble microbial products (SMP).

Practical Ways to Control and Mitigate Fouling

Fouling mitigation works best when strategies are combined and consistently applied. Here are practical, field-proven steps teams use.Operational controls

- Run membranes in constant flux mode where feasible, or carefully manage constant transmembrane pressure to avoid sudden stress.

- Keep mixed liquor suspended solids within target ranges and control sludge retention time to limit excess biomass and SMP production.

Physical measures

- Use air scouring and intermittent backwashing to dislodge cake layers before they compact.

- For side-stream units, maintain adequate cross-flow shear to reduce deposit buildup.

Membrane selection and surface treatment

- Choose hydrophilic membranes or membranes with smoother surface roughness to lower fouling tendency.

- Consider polymeric membranes like PVDF for general use and ceramic modules where cleaning frequency is high.

Chemical cleaning and monitoring

- Schedule periodic chemical cleaning cycles, alternating alkaline and acidic cleaners to remove organic and inorganic fouling respectively.

- Track permeation flux and TMP recovery after each clean to judge cleaning effectiveness.

Applications and Innovations in MBR Technology

Membrane bioreactor technology is flexible, and we see it applied across municipal and industrial settings. In municipal wastewater plants, submerged MBRs are popular for compact footprint and reliable treated effluent, often fed into tertiary trains for water reuse. For industrial wastewater treatment, side-stream MBRs or robust tubular modules handle high-strength streams and variable loads. Current innovations to watch:- Advanced membrane materials, including improved PVDF blends and coated surfaces that reduce fouling and tolerate intensive chemical cleaning.

- Hybrid systems, such as anaerobic MBRs or MBRs coupled with microbial fuel cells, which cut energy use or boost pollutant removal for specific industrial wastes.

- Smart monitoring, where sensors and analytics predict fouling events, optimize aeration, and recommend cleaning schedules before performance drops.

- Integration with polishing steps, like reverse osmosis, for applications that require near-potable quality or specific reuse streams.