Wastewater Treatment Systems

- Treatment of wastewater from industrial processes

- Removal of metals, oils, organics/inorganics, and total dissolved solids (TDS)

- Water reuse

CWP & BWP

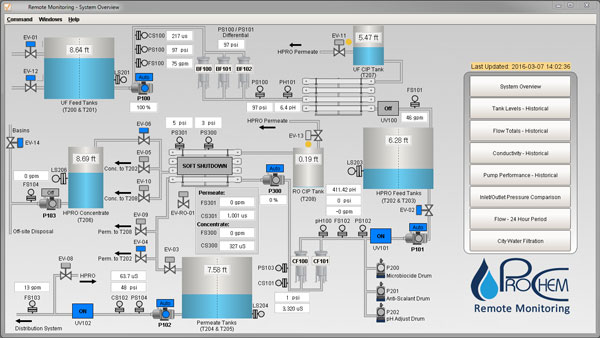

ProChem's CWP (Continuous Flow Wastewater Treatment System) and BWP (Batch Wastewater Treatment System) systems are designed to bring discharge permit compliance to high-volume dischargers and for complex or variable wastestreams. These systems are controlled with a high-degree of automation and remote monitoring technology, complete with alerts to mitigate events and prevent downtime in production.

Both the CWP and BWP are available with multiple system and sizing options. They are ideal for industrial process wastewater prior to discharge or reuse, pH adjustment, metals removal, and solids removal.

The ProChem Advantage

- Custom chemical programs using automated:

- Metering pumps to control dosing

- Air operated diaphragm pumps

- Adjustable chemical addition using the HMI based on flowrate from sensors

- Agitators on variable frequency drives

- Adjustable flow rates

- Custom-built solutions to fit any space

- Customized clarification options

- Used as pretreatment to other filtration products (I-Micro, I-Ultrafiltration, I-PRO, S-PRO)

- Sludge management

- Automated decanting process

- Filter Press

- Automated sludge drying

- Automatic plate shifter and shaker

- Custom built day tanks for chemicals

- Trending capabilities/sensors used:

- Flow

- Conductivity

- pH

- ORP

- Turbidity

- Feed tank level

- Heavy metals

- Pressure

- Level

- ...and many other parameters

Membrane Filtration

- Water reuse

- High-volume water use (overstressed POTW)

- High-purity water applications

- Process water purification

- Ion-exchange pretreatment

- Removal of: metals, glycols, ions (sulfate & nitrogen compounds), oils, grease, organics, machining oils/hydraulic fluids, ink, total suspended solids (TSS), cooling lubricants/drilling emulsions, and other contaminants found in industrial wastewater

- Feed water purification

- Cleaning and rinsing process pretreatment systems

- Desalination

Industrial-Grade Reverse Osmosis Equipment

ProChem’s I-PRO™, B-PRO™, and S-PRO™ utilize pressure to meet the stringent water quality requirements of any facility. They can achieve reuse rates of 95%, have a small footprint, and offer low-energy and low-fouling membrane options.

I-PRO: Membrane Treatment Technology for Industrial Applications, High TDS. An improvement upon standard RO equipment, I-PRO can treat high total dissolved solids (TDS) for a high recovery rate and discharge reduction. I-PRO is ideal for achieving discharge compliance, recycling/reusing wastewater, and for meeting minimal liquid discharge (MLD) and zero liquid discharge (ZLD) goals

B-PRO: Membrane Treatment Technology for Industrial Applications, Mid-Range TDS. Operating at lower pressure than the I-PRO, the B-PRO provides reliable purification at a lower capital cost. It’s ideal for achieving discharge compliance, recycling/reusing wastewater, and for meeting minimal liquid discharge (MLD) and zero liquid discharge (ZLD) goals.

S-PRO: Industrial Reverse Osmosis System. S-PRO is designed for lower TDS and operating pressures than the I-PRO and B-PRO. It’s ideal for city or well water purification, lower TDS wastewater treatment, discharge compliance, and water recycling and reuse. In addition, it has a lower capital cost than I-PRO and B-PRO.

Standard Operating Parameters |

|||

| System | TDS Limit | Operating Pressure | Flow Rate |

| I-PRO | 5,000 - 45,000 mg/l | 800 - 1200 psi | 15 - 350 gpm |

| B-PRO | 10 - 5,000 mg/l | 400 - 600 psi | 10 - 350 gpm |

| S-PRO | 10 - 2,000 mg/l | 200 - 400 psi | 10 - 350 gpm |

I-Micro: Microfiltration

I-Micro is designed to remove total suspended solids. It can be used as a secondary polish or clarifier replacement. The I-Micro is ideal for TSS removal, as a pretreatment for I-PRO and B-PRO, as a component to water reuse systems, and to replace a conventional clarifier (with a smaller footprint). It provides absolute filtration in multiple micron ranges, is easy to operate, and can incorporate ceramic and polymeric membrane options as well as PVC and stainless-steel pressure vessel options.

I-UF: Ultrafiltration

I-UF is designed to remove non-soluble and colloidal contaminants such as organics and oil and grease. It’s ideal for pretreatment for I-PRO or selective ion-exchange systems, landfill leachate treatment, organic chemical wastewater, and oily wastewater treatment and recovery. It can be designed for multiple modes (high or low crossflow and dead end) with ceramic, polymeric, and polyfiber ultrafilters and can incorporate spiral-wound and tubular design options.

Specialty Ion-Exchange

- Contaminant removal

- Dealkalization

- High-purity water

- Metals removal

- Total dissolved solids (TDS) removal

ProChem’s specialty ion-exchange systems offer minimal capital investment, reduced operational interaction, and multiple column configurations to meet space, flow, and performance needs. They can be designed to integrate into existing wastewater treatment systems and include the option to utilize portable ion-exchange program (offsite regeneration).

Process Water Treatment

SBX™: Industrial Water Softening System. SBX offers a twin alternating option for continuous flow of soft water at any flow rate. It is ideal for meeting hardness requirements, scale reduction, and boiler protection.

DBX™: Industrial Deionization System for High-Purity Water Applications. DBX removes ions (such as metals and salts) from water or wastewater, providing an optimal purity for many applications. It is ideal for high-purity water applications, laboratory water, and electronics manufacturing process water.

CBX™: Activated Carbon Filtration Technology. CBX removes chlorine compounds and organics from industrial process water.

Wastewater Treatment

- Metaloc™: Metals selective ion-exchange technology.

- Organiloc™: Selective ion-exchange technology for organic compounds.

- Anionloc™: Selective ion-exchange technology for anionic compounds.

- Noxloc™: Ion-exchange technology to selectively remove nitrogen compounds and ammonia compounds.