Blog

Read articles and the latest industry news from ProChem Inc.

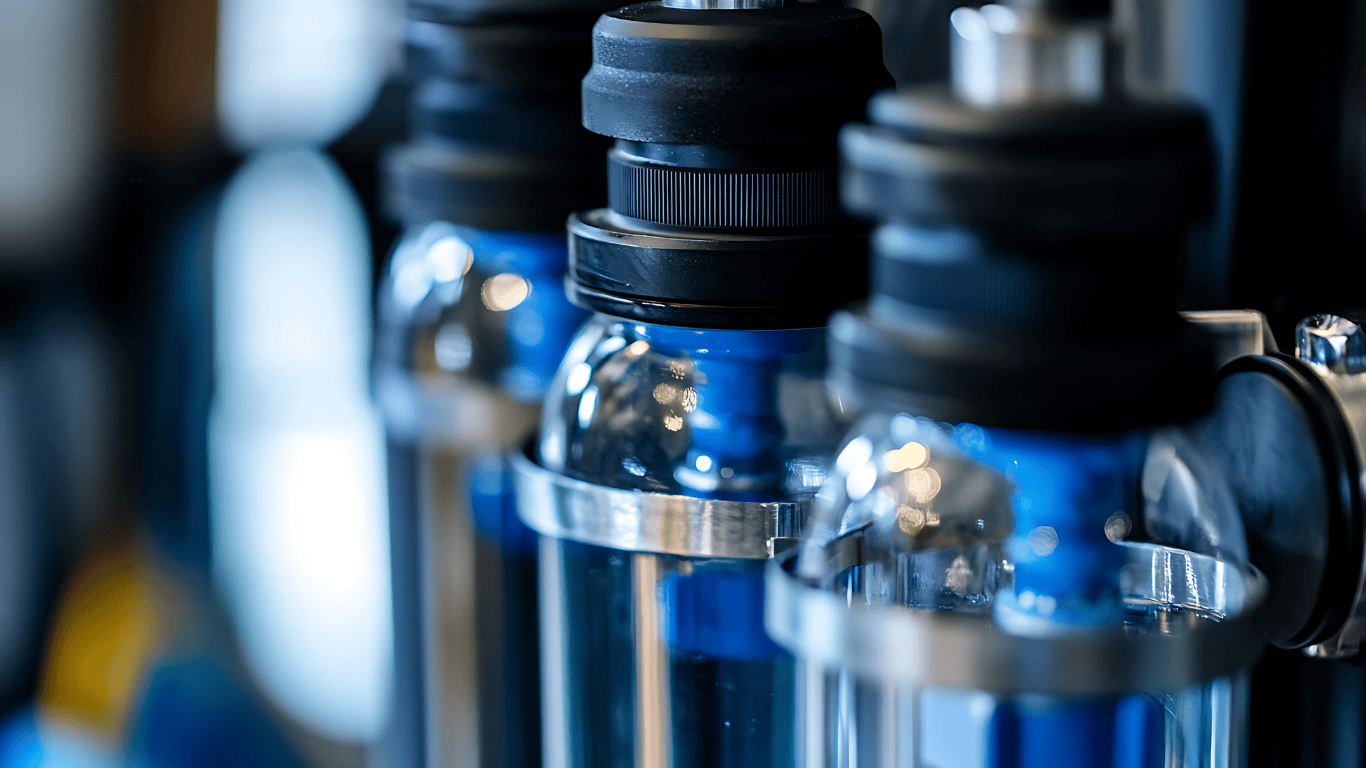

Heavy Metal Water Filter: Safe & Clean Water

- Category: Filtration & Water Quality

Clean water is a foundation for health, safety, and efficient operations in any facility. Unfortunately, water can carry hidden risks, including heavy metals like lead, mercury, and arsenic. These substances aren’t just a concern for drinking water. They can also affect plumbing fixtures, appliances, and the overall performance of your facility’s water systems. That’s why using a heavy metal water filter is a key step in protecting both your team and your operations.

In this article, we’ll explore how heavy metal water filters work, the different types available for facilities, and practical steps you can take to ensure your water remains clean, safe, and reliable. We’ll also share guidance on maintenance, monitoring, and combining filters with other water treatment methods to deliver consistent results.What Are Heavy Metals in Water?

Heavy metals are naturally occurring elements that become harmful at high levels. In water systems, these substances can come from old pipes, industrial processes, or certain plumbing fixtures. While small amounts may not cause immediate issues, prolonged exposure can affect both health and facility equipment.Common Heavy Metals to Watch For

- Lead: Often leaches from aging pipes, especially in older buildings. It’s a serious health concern even at low levels.

- Mercury: Can enter water through industrial runoff and affects nervous system functions.

- Arsenic: Typically found in groundwater, high levels are toxic and can contaminate tap water.

- Iron and Manganese: While not always harmful to health, they can stain surfaces, impact taste, and affect appliances.

- Copper: Leaches from plumbing pipes, especially in high-pressure systems, and can affect both taste and safety.

Why Monitoring Heavy Metals Matters

Facilities that rely on tap water for operations or drinking water must stay vigilant. High levels of heavy metals can damage appliances, create odor or taste issues, and even increase plastic waste if bottled water becomes the fallback. Operators often catch early issues by testing water regularly, observing changes in color, smell, or sediment, and ensuring proper water treatment measures are in place.How Heavy Metal Water Filters Work

Understanding how a heavy metal water filter works helps you choose the right system and maintain it effectively. Filters remove harmful substances by targeting specific contaminants, including heavy metals, chemicals, and sediment, while allowing water molecules to pass through cleanly.Activated Carbon Filters

- These filters trap impurities like chlorine, hydrogen sulfide, and some other substances that affect taste and odor.

- While excellent for improving drinking water quality, they are less effective against certain heavy metals unless combined with other filtration methods.

Reverse Osmosis Filters

- Reverse osmosis (RO) filters push water through a semi-permeable membrane, removing dissolved metals such as lead, arsenic, and mercury.

- RO filters are highly effective because they physically separate water molecules from contaminants, delivering clean water suitable for drinking or sensitive operations.

Filter Cartridges and Multi-Stage Systems

- Many systems combine activated carbon and reverse osmosis filters in multi-stage filtration systems.

- Filter cartridges trap sediment, dirt, and remaining heavy metals, ensuring water is not only safe but also tastes better.

- Operators should monitor cartridge lifespan to maintain high-pressure performance and prevent clogging.

Types of Heavy Metal Water Filters

Choosing the right heavy metal water filter depends on your facility’s size, water usage, and specific needs. Understanding the types of water filters available helps operators make informed decisions and protect both appliances and plumbing.Point-of-Use Filters

- Installed directly at a kitchen sink or tap, these filters provide filtered water for drinking, cooking, or small-scale operations.

- Ideal for facilities that need targeted protection in specific areas without investing in a full whole house system.

- Commonly use activated carbon filters or small reverse osmosis cartridges.

Whole-House Filters

- Treat water for the entire facility, ensuring all taps, plumbing fixtures, and appliances receive clean water.

- Typically larger filtration systems with multi-stage filter cartridges that remove sediment, hard water minerals like calcium and magnesium, and heavy metals.

- Helps reduce odor, taste, and dirt issues throughout the building.

Other Considerations

- Some systems combine point-of-use and whole home solutions for comprehensive protection.

- Installation and maintenance are critical. Filters must be replaced regularly to maintain performance.

- Operators often choose systems based on high-pressure capabilities, water usage, and the types of contaminants present.

Benefits of Installing Heavy Metal Water Filters

Investing in a heavy metal water filter brings multiple advantages for both health and facility operations. Operators often notice improvements in taste, safety, and equipment longevity when filters are installed and maintained correctly.Protect Health and Safety

- Removes harmful substances such as lead, arsenic, mercury, and other chemicals.

- Ensures drinking water is safe for staff, visitors, and operational processes.

- Reduces exposure to bacteria and other contaminants that may cause health concerns.

Improve Taste and Odor

- Filters help remove chlorine, hydrogen sulfide, and sediment, improving overall water taste and smell.

- Reduces reliance on bottled water or additional flavoring, which also helps minimize plastic waste.

- Supports better drinking water experiences in kitchen sinks and point-of-use areas.

Protect Equipment and Plumbing

- Removes heavy metals and hard water minerals like calcium, magnesium, and manganese levels that can damage appliances, pipes, and fixtures.

- Prevents buildup that affects plumbing fixtures, drains, and operational efficiency.

- Reduces maintenance needs and extends the lifespan of equipment.

Maintenance and Lifespan of Filters

A heavy metal water filter only works effectively when it’s properly maintained. Teams that stay on top of filter cartridge replacement and monitor water conditions prevent sediment, dirt, and other substances from compromising clean water and safe water standards.Replacing Filter Cartridges

- Most filter cartridges have a recommended lifespan based on how much water passes through the system.

- Signs a cartridge needs replacement include reduced water flow, changes in taste or odor, and visible sediment or dirt buildup.

- Following manufacturer installation guidelines ensures optimal performance and prevents high-pressure issues.

Monitoring Water Quality

- Regular testing helps operators catch early changes in contaminants, hard water minerals, or chemicals that may affect appliances or pipes.

- Keep an eye on unusual smell, discoloration, or increased bacteria levels to ensure safe water.

Tips for Long-Term Performance

- Schedule routine inspections and filter system maintenance.

- Maintain proper installation to prevent leaks or reduced efficiency.

- Combine filters with other water treatment steps, like distillation or osmosis, if needed for specific heavy metals or hydrogen sulfide removal.

Steps to Ensure Optimal Water Quality

Maintaining clean water in your facility requires more than just installing a heavy metal water filter. Teams should actively monitor, maintain, and complement filters with other water treatment methods to protect health, equipment, and overall operations.Regular Testing and Monitoring

- Test water for heavy metals, chlorine, bacteria, and other contaminants on a routine schedule.

- Observe changes in taste, odor, sediment, or dirt, which can signal the need for maintenance or filter replacement.

- Track manganese levels, hard water minerals like calcium and magnesium, and copper or iron content to prevent equipment buildup.

Combine Treatment Methods

- Use activated carbon filters, reverse osmosis, or distillation as needed for comprehensive water treatment.

- Incorporate filters at kitchen sinks, point-of-use taps, or whole home/whole house systems depending on operational needs.

- Address hydrogen sulfide, odor, and other chemicals early to maintain safe water quality.

Operator Guidance

- Teams should watch for pipes or appliances showing signs of heavy metal accumulation.

- Avoid relying solely on bottled water. A well-maintained filtration system provides consistent filtered water and reduces plastic waste.

- Document maintenance schedules, filter cartridge replacements, and testing results for ongoing monitoring.