Water quality sensors have become one of the most practical tools for modern facilities. They help teams track key water parameters in real time, keeping processes efficient and compliant. In many industrial settings, these sensors serve as the first line of defense against contamination, equipment wear, and costly shutdowns.

In this article, we’ll explore how water quality sensors work, what parameters they measure, and how facilities can analyze data in real time to support regulatory compliance and long-term efficiency. We'll also share how these devices connect with monitoring software and control systems to transform how industries manage water across various applications.Why Continuous Water Quality Monitoring Matters

Industrial facilities rely on consistent, accurate water quality data to keep operations stable and compliant. Continuous water quality monitoring allows operators to collect data, detect issues in real time, and make informed decisions before small variations in water parameters lead to major process or equipment problems.1. Ensuring Regulatory Compliance

Facilities must meet strict water discharge and process standards. With a water quality sensor, teams can track pH, conductivity, turbidity, and dissolved oxygen levels continuously; helping maintain regulatory compliance and avoid costly penalties. Automated data logging and reports simplify audits and documentation, saving both time and effort.2. Protecting Equipment and Infrastructure

Changes in water quality directly affect corrosion, scaling, and buildup inside pipes and cooling systems. Continuous monitoring enables early detection of contaminants, unbalanced oxygen levels, or irregular pressure readings, factors that can shorten equipment lifespan or reduce process efficiency.3. Optimizing Process Control and Efficiency

By using real-time data from sensors, facilities can adjust control parameters, chemical dosing, and flow rates more precisely. This optimization reduces chemical waste, supports energy efficiency, and ensures each system operates at peak performance.4. Supporting Environmental Responsibility

Reliable water quality monitoring not only ensures compliance but also demonstrates environmental accountability. Continuous tracking of wastewater, nitrate, ammonium, and nitrite levels helps facilities prevent harmful discharges into sources such as rivers or seawater, reinforcing sustainability goals.5. Improving Decision-Making with Connected Data

Modern sensors connect to monitoring software and mobile apps, allowing teams to analyze data and make predictions on system performance. This connected approach provides early warnings, ensures accurate measurements, and supports smart project planning for system upgrades or product selection.How Water Quality Sensors Work

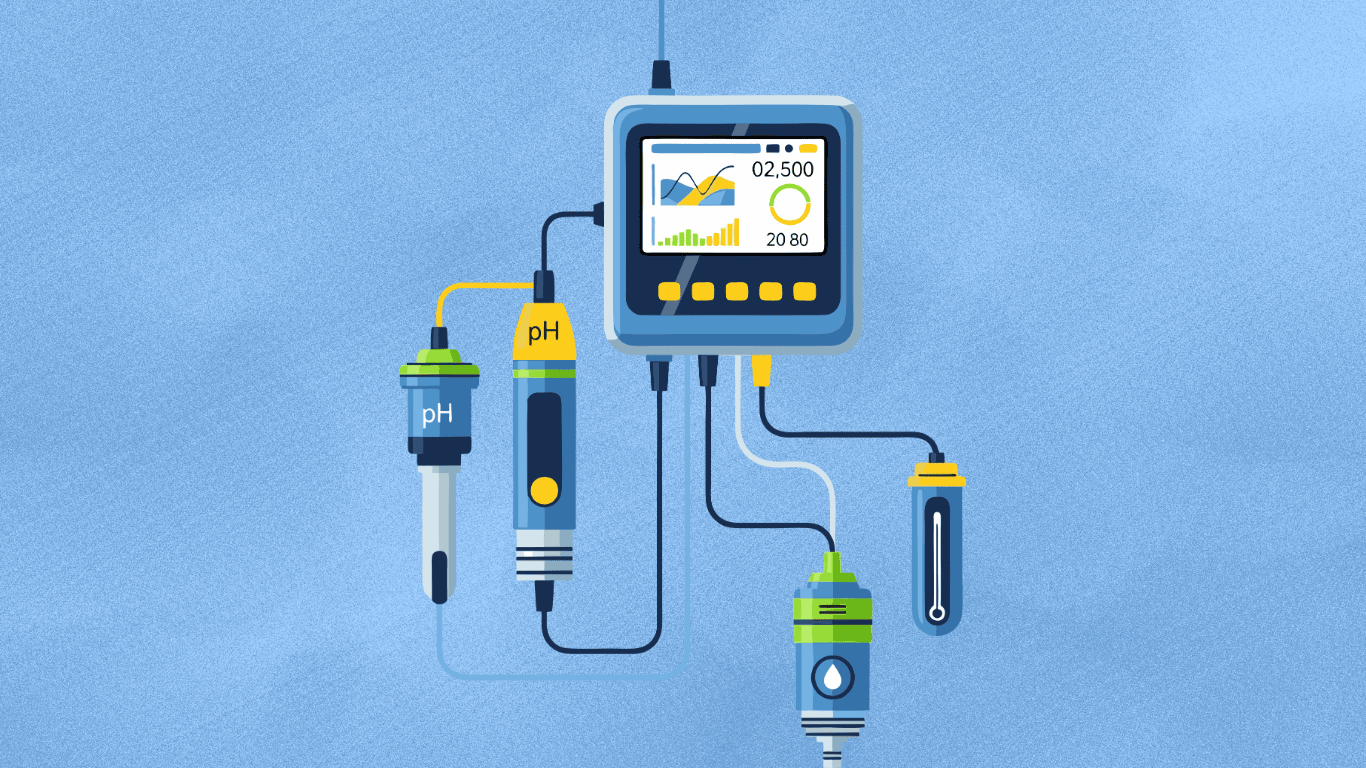

A water quality sensor is designed to detect and quantify various water parameters in real time, giving operators a continuous overview of system health. These devices collect and transmit water quality data that can be used to fine-tune control systems, ensure regulatory compliance, and prevent costly downtime.1. Collecting and Measuring Key Parameters

Each sensor measures specific parameters such as pH, conductivity, temperature, turbidity, dissolved oxygen, chloride, salinity, and TDS (total dissolved solids). These values reveal whether the water is clean, balanced, and suitable for its intended applications.2. Data Conversion and Transmission

Once readings are taken, the sensor converts them into electrical signals that are sent to a meter, controller, or data logging system. This allows operators to collect data, analyze data, and detect patterns or irregularities that manual testing might miss.3. Integration with Monitoring and Control Systems

Modern water quality sensors connect to monitoring software, SCADA systems, or mobile apps. This connectivity enables real-time alerts, trend tracking, and predictions about system behavior. Operators can adjust pressure, dosing, or filtration settings automatically, based on the data received.4. Designed for Industrial Environments

Industrial-grade sensors are built to withstand harsh conditions such as high pressure, variable temperature, and exposure to contaminants. Whether used in wastewater, process water, or seawater monitoring, these devices are designed to deliver stable readings over long periods, even in corrosive or high-load environments.5. From Data to Decision-Making

Accurate water quality data allows teams to optimize operations, reduce maintenance costs, and improve sustainability outcomes. By using monitoring software to track trends and generate reports, facility managers can make informed decisions on treatment strategies, product selection, and system maintenance schedules.Single vs. Multi-Parameter Sensors

Every facility’s water quality monitoring needs are different. Choosing between single and multi-parameter sensors depends on what water parameters you need to measure, the level of data you want to collect, and your overall system setup. Both devices serve important roles in maintaining consistent water quality and operational efficiency.1. Single-Parameter Sensors

A single-parameter water quality sensor focuses on one variable—such as pH, conductivity, temperature, or dissolved oxygen.- Advantages:

- High precision for individual parameters critical to compliance and process control.

- Easier calibration and maintenance compared to multi-parameter probes.

- Ideal for monitoring wastewater, boiler feedwater, or specific water treatment stages.

- Applications: Facilities that require tight control over key indicators like oxygen or turbidity levels.

2. Multi-Parameter Sensors

A multi-parameter sensor combines several measurement functions into one unit. These advanced devices can monitor pH, conductivity, turbidity, temperature, nitrate, nitrite, ammonium, and chloride simultaneously.- Advantages:

- Reduces installation complexity and data logging points.

- Provides a complete water quality data profile in real time.

- Compatible with monitoring software, apps, and control systems for easier data management.

- Applications: Ideal for projects that require full-system analysis such as seawater studies, process water, or wastewater treatment operations.

3. Selecting the Right Option

When choosing between single and multi-parameter sensors, consider:- Your monitoring goals (e.g., regulatory compliance, process efficiency, or environmental performance).

- The environmental conditions (e.g., high pressure, temperature swings, or exposure to contaminants).

- Your budget and long-term maintenance capacity, while multi-parameter models may seem expensive, they often reduce installation and calibration time in the long run.

Choosing the Right Sensor for Your System

Selecting the right water quality sensor is an important step toward maintaining efficient and compliant facility operations. The ideal device depends on your specific applications, required water parameters, and the operational conditions in which it will function.1. Define Your Monitoring Goals

Start by identifying why you’re conducting water quality monitoring. Is it for regulatory compliance, corrosion prevention, or process optimization?- For wastewater systems, focus on ammonium, nitrite, nitrate, and turbidity.

- For cooling systems or seawater applications, prioritize salinity, conductivity, and chloride levels.

- For chemical or manufacturing projects, key indicators include pH, oxygen, and temperature. Understanding these parameters ensures you measure what truly impacts your process efficiency.

2. Consider Environmental Conditions

Industrial environments vary in pressure, temperature, and exposure to contaminants. Choose sensors that are designed for your system’s operating range.- High pressure or high-temperature systems need reinforced probe housings.

- Corrosive environments, such as wastewater or brine, require specialized materials resistant to chemical attack.

3. Evaluate Data Integration Capabilities

Modern sensors can connect with monitoring software, SCADA platforms, and mobile apps.- Look for devices that support data logging, remote access, and automatic control adjustments.

- This digital connectivity allows operators to collect data, analyze data, and make predictions that improve efficiency in real time.

4. Balance Cost with Long-Term Value

While some water quality sensors may appear expensive upfront, consider the total lifecycle cost.- Durable products with self-cleaning features and low calibration frequency reduce maintenance time and replacement expenses.

- Reliable data means fewer disruptions and more accurate system decisions.

5. Consult Experts and Explore Options

Before finalizing your sensor selection, explore different products and seek advice from professionals experienced in industrial water quality monitoring.- Ask questions about performance in your specific applications.

- Check compatibility with existing systems and control infrastructure.

- For students or engineers working on a project, comparing featured products on the market can help you learn how technology supports process reliability and sustainability goals.

Maintenance and Calibration Tips

To ensure consistent accuracy and reliability, every water quality sensor needs regular maintenance, cleaning, and calibration. Proper care helps extend the life of your devices, maintain stable water quality data, and prevent costly system issues caused by inaccurate readings.1. Follow a Regular Maintenance Schedule

Routine sensor maintenance minimizes fouling, scaling, and corrosion.- Clean sensors regularly: Remove debris, scale, and biofilm to maintain accuracy.

- Check for wear: Inspect cables, O-rings, and connectors for damage or leaks.

- Monitor performance: Sudden fluctuations in data could signal buildup or probe failure.

2. Keep Calibration Frequency Consistent

Different sensors have unique calibration intervals. Some weekly, others monthly or quarterly.- Use certified calibration standards to maintain compliance and consistent measurements.

- Document each calibration for traceability and easier data logging.

- Some advanced water quality sensors are designed with automatic calibration and accuracy check features to simplify upkeep.

3. Conduct Routine Accuracy Checks

Regular accuracy checks verify sensor performance between calibrations.- Compare readings to laboratory results or known standards.

- Track parameters such as pH, conductivity, temperature, and dissolved oxygen to ensure reliable data.

4. Practice Preventive Maintenance

A proactive preventive maintenance plan keeps your monitoring system performing at its best.- Inspect pipes, seals, and housings for leaks or scaling.

- Replace worn components early to prevent downtime.

- Verify that all control and monitoring software connections remain stable.

5. Handle and Store Sensors Properly

When not in use, store sensors according to manufacturer guidelines.- Moisture control: Certain probes, like pH or oxygen meters, need to be stored in solution.

- Temperature management: Avoid extreme heat or freezing conditions that can damage internal components.

- Safe handling: Protect probes from impact and pressure changes during transport.