When people ask us how to reduce water use, we always tell them it starts with awareness. Most of us don’t realize how much water we go through each day, until we see the bill or notice a small leak turning into gallons of water lost.

In the following sections, we’ll walk through practical, proven ways to save water, improve efficiency, and create a more sustainable environment for your facility and community.The Basics: Fix Leaks and Optimize Plumbing

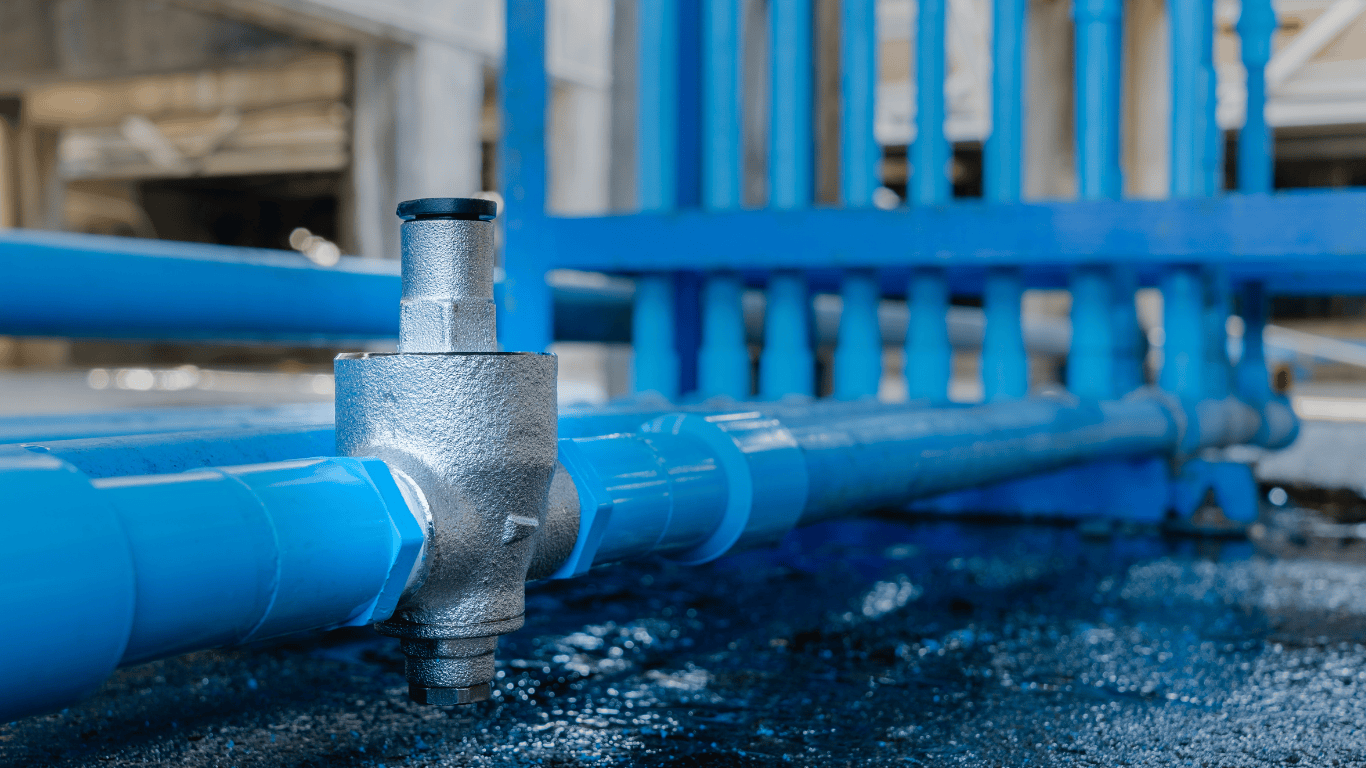

If you’re serious about learning how to reduce water use, start with what’s often overlooked: plumbing. Even small drips from hoses, process lines, or slow leaks in facility valves can waste thousands of gallons of water each year. These aren’t minor issues—they quietly raise your water usage and energy bills while contributing to water loss.1. Check for Leaks Regularly

Most facilities lose more water than they realize through small, undetected leaks. To stay ahead:- Schedule periodic inspections of all plumbing fixtures and irrigation systems.

- Watch for signs like low water pressure or continuous faucet run in process lines.

- Fix leaks in valves, taps, and seals immediately.

2. Upgrade to Smarter Fixtures

If your facility still relies on older models, it’s time for an update:- Replace outdated plumbing fixtures with low-flow or WaterSense-labeled valves designed for efficiency.

- Check irrigation systems for overwatering or poor sprinkler alignment to prevent runoff and reduce water waste.

- Implement more efficient process line setups to minimize unnecessary water consumption.

Upgrade to Efficient Fixtures and Appliances

Once leaks are under control, the next step in learning how to reduce water use is upgrading your fixtures and equipment. Outdated systems waste more water and energy than you might expect, and the savings from modern replacements often pay for themselves over time.1. Choose Water- and Energy-Efficient Options

Look for WaterSense or ENERGY STAR labeled fixtures and equipment. These models deliver top performance while using less water and energy:- Low-flow faucets, valves, and process line fittings reduce water consumption without affecting water pressure.

- Efficient rinse systems, cooling equipment, or washers for industrial cleaning save hundreds of gallons of water annually, especially when operated at full capacity.

- Smart toilet fixtures or flush mechanisms in facilities can use up to 60% less water compared to older models.

2. Think Beyond Fixtures

Small operational habits also make a difference:- Run industrial cleaning, rinsing, or cooling systems only when fully loaded or needed.

- Use cold water cycles in processes when heating isn’t required to save energy and lower energy bills.

- Shut off hoses, taps, or valves when not in active use to prevent water waste.

Improve Water Use in Cooling and HVAC Systems

For many commercial facilities, HVAC and cooling systems quietly account for a large share of total water consumption. If you want to know how to reduce water use effectively, start by looking at how your system cools, cleans, and circulates water. Even small adjustments can translate to major savings.1. Schedule Regular Maintenance

Keeping your HVAC system in good condition is one of the simplest ways to save water and energy.- Check cooling towers for leaks, mineral buildup, or overflowing basins.

- Inspect filters, valves, and pumps to ensure proper operation and consistent water pressure.

- Clean heat exchangers and coils regularly to prevent inefficiencies that waste water and energy.

2. Adopt Water-Saving Technologies

Consider investing in air-cooled chillers or smart control systems that automatically regulate flow and reduce evaporation losses. Some facilities also repurpose condensate or use non-potable water from reclaimed sources for cooling, an approach that helps reduce evaporation and reliance on fresh water. These upgrades not only save water but also lower operational costs and improve overall system efficiency.Recycle and Reuse: Turning Wastewater into a Resource

One of the most effective ways to reduce water use is to make the most of what you already have. Many facilities now recycle or reuse treated wastewater for non-potable purposes. This not only saves drinking water but also reduces the strain on local water resources.1. Recycle Process Water

Treated wastewater can often be reused safely for:- Cooling and rinsing operations in industrial settings

- Irrigation systems for landscaping or outdoor areas

- Equipment cleaning where potable water isn’t required

2. Invest in Smart Recycling Systems

Modern treatment technologies, such as membrane bioreactors and filtration units, can effectively recycle water within your system. This minimizes discharge, reduces water loss, and supports sustainability goals. Facilities that recycle water not only save on supply and treatment costs but also strengthen their environmental stewardship. The goal is to use every drop more than once before it leaves your facility.Smarter Water Management: Monitoring and Control

Once your systems are running efficiently, the next step is tracking how much water you actually use. Monitoring is what turns good intentions into measurable results. Without it, even well-designed systems can waste water quietly over time.1. Install Water Meters and Tracking Devices

Modern water meters provide real-time data on consumption across different parts of your facility. Use that data to:- Identify where most of your water usage occurs.

- Detect leaks or unusual spikes that may signal a problem.

- Compare consumption between departments or processes.

2. Automate for Efficiency

Pairing meters with automated control systems lets you adjust water flow and timing automatically based on demand. For example:- Smart irrigation systems that prevent overwatering.

- Automated valves that shut off when flow exceeds preset limits.

Build a Culture of Water Awareness

Technology can make a big difference, but lasting water conservation starts with people. When everyone in your facility understands how to reduce water use, the results multiply. Building awareness is about turning water-saving habits into everyday practice.1. Train and Empower Your Team

Hold short, practical training sessions that show employees where water is most often wasted and how to avoid it.- Remind teams to report leaks, running water, or faulty fixtures right away.

- Encourage simple habits like shutting off taps, using a washing up bowl, or collecting rinse water for cleaning.

2. Recognize and Reward Conservation Efforts

People respond to recognition. Celebrate departments or teams that show measurable improvement in water efficiency. Over time, that positive culture helps reduce water usage, lower your carbon footprint, and create a shared sense of responsibility for the environment.Everyday Water-Saving Practices That Add Up

One of the easiest ways to save water in facilities is to operate equipment only at full capacity and avoid running rinse lines unnecessarily. Collect rinse or cooling water for reuse in other processes. Shutting off hoses, taps, or valves when not in use prevents water waste and reduces overall water consumption.1. Smarter Water Use Indoors / In Facilities

- Use collection tanks or buckets to capture rinse or process water for reuse rather than letting it go to drain.

- Run industrial cleaning or rinsing systems only at full capacity to avoid unnecessary water loss.

- Avoid excessive flushing in process lines; redirect greywater for safe reuse whenever possible.

- Shut off hoses and taps immediately when not in active use.

- Switch to cold water cycles in cooling or process systems when heating isn’t necessary to save energy and reduce utility costs.

2. Smarter Water Use Outdoors

- Cover cooling towers, storage tanks, or outdoor reservoirs to reduce evaporation.

- Schedule irrigation or outdoor cleaning for cooler hours, like early morning or late afternoon, to retain moisture and avoid runoff.

- Collect rainwater using water butts or tanks for landscaping, irrigation, or non-potable process use. It’s free, sustainable, and efficient.